ComprehensIve daTa Tables

www.DaikinApplied.com 5 ED 15103-6 • MICROTECH III WSHP UNIT CONTROLLER

ComprehensIve daTa Tables

BACnet Network Objects

The following section contains relevant information needed

to integrate a MicroTech III WSHP into the BACnet network.

The data point differences between the Ennity

™

Single Stage

Compressor, and the SmartSource

®

Two Stage Compressor

and Ennity Large Two Compressor models are highlighted

below in the following tables:

• Table 1 - Table 7: Ennity Single Stage Compressor

models MHC/MHW, CCH/CCW, VFC/VFW, LVC/LVW,

VHC/VHF (notes for all tables are shown at the end of

Table 7)

• Table 8 - Table 14: SmartSource Single and Two Stage

Compressor models GSH/GSV, GTH/GTV, GCV; Ennity

Large Two Compressor models CCH/CCW, LVC/LVW

(notes for all tables are shown at the end of Table 14)

The Selected Parameters Information section describes Binary

Input Status and Binary Output Status settings in greater detail.

CAUTION

Please note that anytime a command is written to a conguration property,

this information is stored in the unit controller’s non-volatile memory. Writing

to non-volatile memory is an operation that has a nite limit. For this reason,

the number of writes made to BACnet objects linked to conguration

properties must be limited to avoid damage to the hardware.

The BACnet Conguration and Commissioning, Effective

Occupancy Modes, and Space Temperature Setpoint Methods

sections provide supplemental conguration and temperature

setpoint operation details. The BACnet PICS for each WSHP

model is included at the end of the document. See Appendix

A: Protocol Implementation Conformance Statements (PICS).

Refer to OM 1085 Software Downloading Procedures and

Troubleshooting Guide, available on www.DaikinApplied.com,

for software part number and compatibility details.

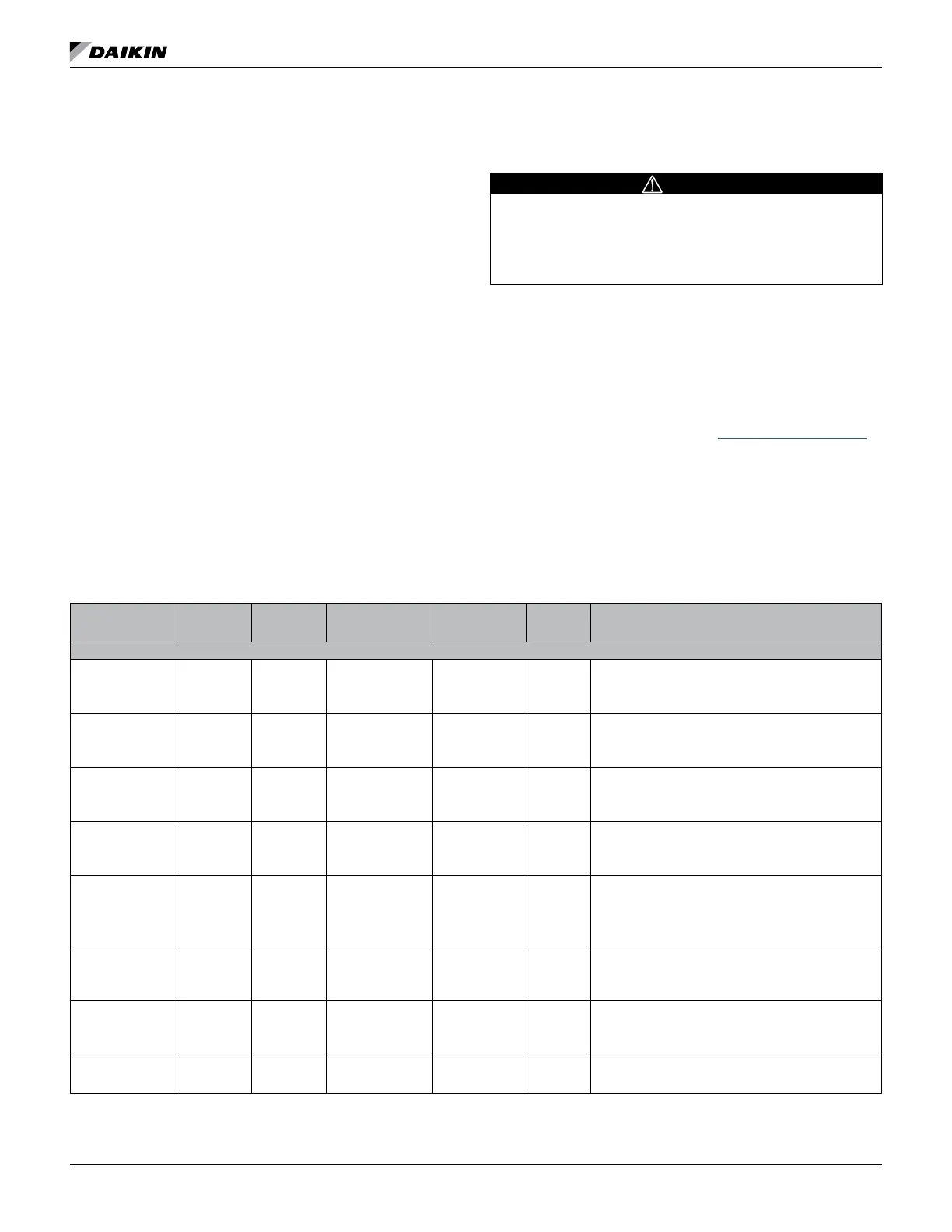

BACnet Data Points - Ennity Single Stage Compressor

Models: MHC/MHW, CCH/CCW, VFC/VFW, LVC/LVW, VHC/VHF

Table 1: Analog Values - Ennity Single Stage Compressor

Point Name

Object Type/

Instance

Read/

Write

Access

2

BACnet Object

Name

Range/Default

(in Units)

Non-

volatile

Memory

1

Description

ANALOG INPUTS

Local Space

Temperature Output

AI:1 R LocalSpaceTemp

0 to 158ºF

-17.77 to 70ºC

Default:

68ºF / 20ºC

N

The value of the hardwired space temperature sensor

installed either in the return air or the space. Writing to

Space Temp Input (AV18) does not affect Local Space

Temp (AI1) but does effect Effective Space Temp (AV22).

6

Leaving Water

Temperature

AI:2 R LWT

0 to 158°F

-17.77 to 70°C

Default:

32ºF / 0ºC

N Displays the leaving water temperature sensor value.

6

Entering Water

Temperature

AI:3 R EWT

0 to 158°F

-17.77 to 70°C

Default:

32ºF / 0ºC

N Displays the entering water temperature sensor value.

6

Discharge Air

Temperature

AI:4 R DischAirTemp

0 to 158°F

-17.77 to 70°C

Default:

32ºF / 0ºC

N Displays the discharge air temperature sensor value.

6

Local Setpoint

Adjust Output

AI:5 R LocalSetpt

55 to 95ºF

12.78 to 35ºC

Default:

32ºF / 0ºC

N

The reference setpoint used to determine the Effective

Heating/Cooling setpoints. It is the value of the local,

hardwired space temperature setpoint. It is only valid if

the unit controller JP5 conguration jumper is congured

for Long Range Setpoint Adjust and is enabled by

MSV14.

6

See Effective Occupancy Modes.

Compressor

#1 Suction

Temperature

AI:6 R SuctionTemp

1

0 to 158°F

-17.77 to 70°C

Default:

32ºF / 0ºC

N

The compressor #1 suction line temperature sensor

value.

6

Compressor

#2 Suction

Temperature

AI:7 R SuctionTemp

2

0 to 158°F

-17.77 to 70°C

Default:

32ºF / 0ºC

N

The compressor #2 suction line temperature sensor

value.

6

Brownout Voltage

Reading

AI:8 R Brownout

0 to 1023 counts

Default: 0

N

The Brownout Voltage Reading is compared to the

reference setpoint to determine if the brownout condition

exists.

Loading...

Loading...