OM 1280-2 • MICROTECH UNIT CONTROLLER 32 www.DaikinApplied.com

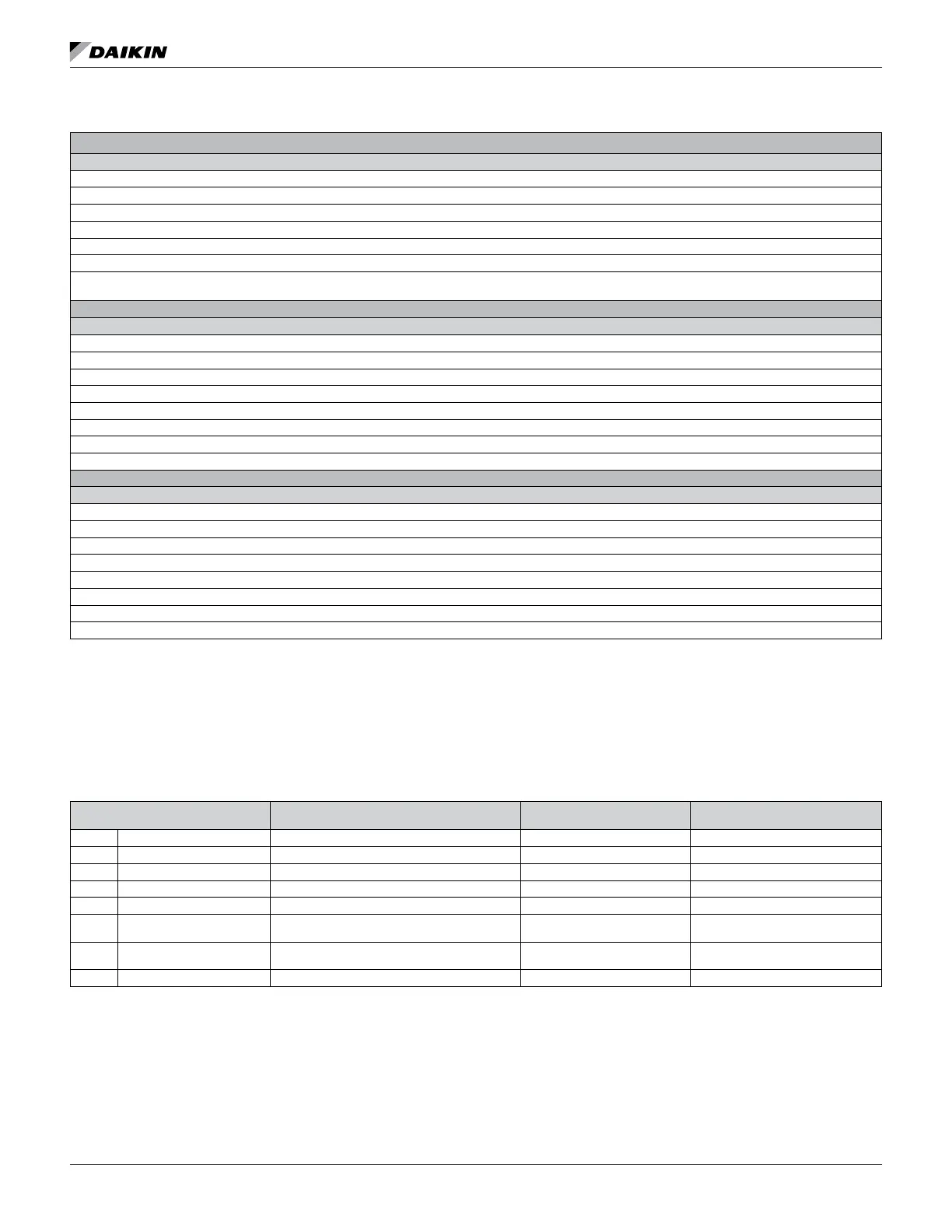

Table 14: Setpoint Calculation Examples

Example A – Stand-Alone Unit, No remote sensor, No network communication

Given

Occupancy Mode = Occupied and Unit Mode = Heat

Space Temp Setpoint = (not used)

Setpoint Shift = (not used) = 0.0°F

OHS = 69.8°F

= 69.8°F + 0.0°F + 0.0°F + 0.0°F = 69.8°F

Example B – Stand-Alone Unit, Remote sensor with 55ºF – 95ºF Setpoint, No network communication

Given

Occupancy Mode = Occupied and Unit Mode = Heat

Space Temp Setpoint = 71.0°F (from remote sensor)

Setpoint Shift = (not used) = 0.0°F

OCS = 75.0°F, OHS = 70.0°F

Example C – Stand-Alone Unit, Remote sensor with +/- 5°F, BACnet network communication

Given

Occupancy Mode = Occupied and Unit Mode = Heat

Space Temp Setpoint = 71.0°F (from network input)

Setpoint Shift = (from network input) = -2.0°F

OCS = 74.0°F, OHS = 68.0°F

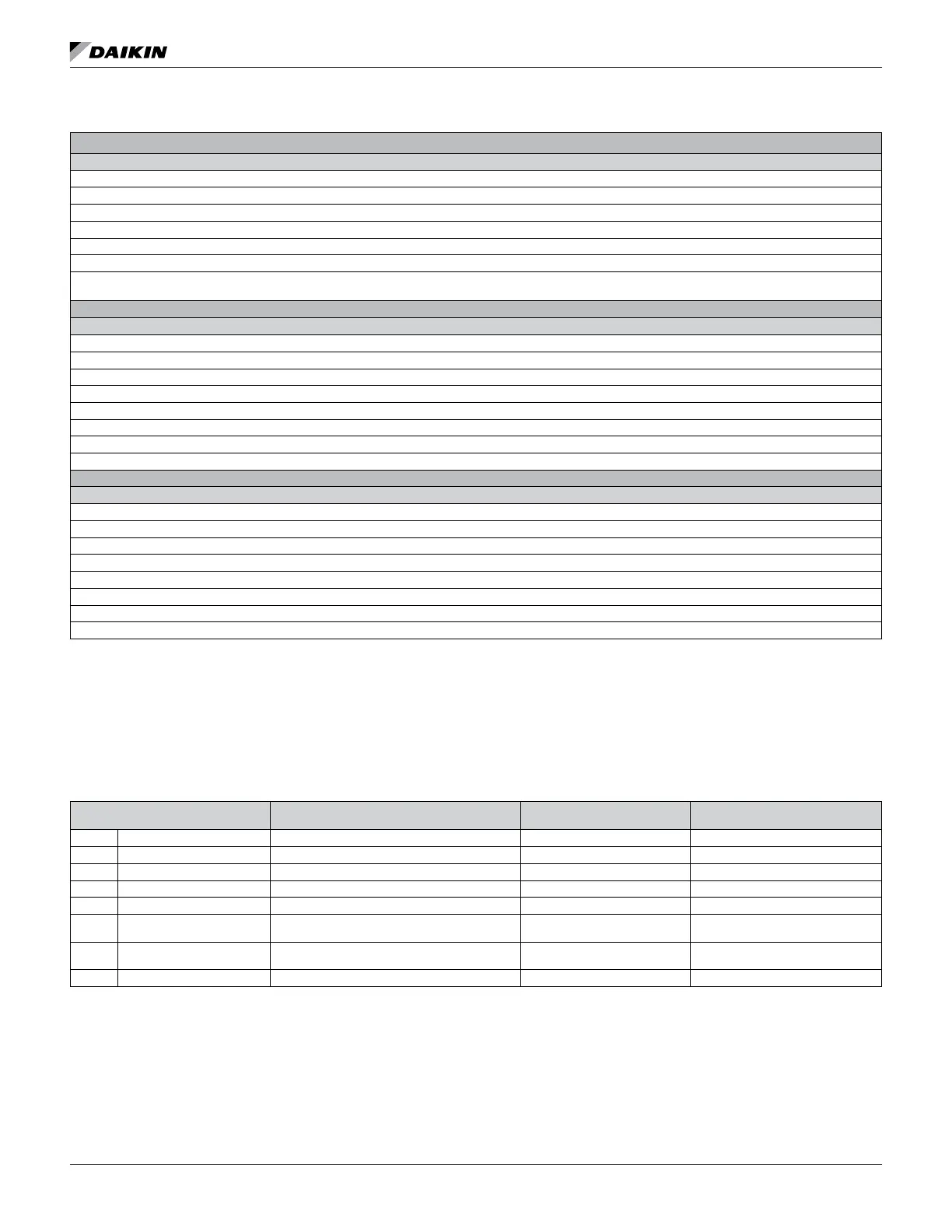

Proportional Integral (PI) Control Loops

The MicroTech UVC uses PI-loop control for heating, cooling

and ventilation processes within the unit ventilator. Numerous

PI algorithms can be used depending upon the unit ventilator

Table 15: PI Loop List

PI loops Setpoint

Feedback

(controlled variable)

Output

PI-1 Single Zone VAV Fan Control Temperature Fan Speed

PI-2 Economizer / Free Cooling Discharge Air Temperature Position the OA Damper

PI-3 Modulating Cooling Valve Discharge Air Temperature Modulating Cooling Valve Position

PI-4 Modulating Hot Water Valve Discharge Air Temperature Modulating Hot Water Valve Position

PI-5 Face and Bypass Damper Discharge Air Temperature Face and Bypass Damper Position

PI-6

CO

2

/ Demand Control

Ventilation

2

Setpoint Space CO

2

Position the OA Damper

PI-7 DAT Low Limit

Setpoint

Discharge Air Temperature Position the OA Damper

PI-8 Electric Heat Discharge Air Temperature Electric Heat Stage

Loading...

Loading...