IM 962-2 13

Installation

Table 9: Recommended Vapor and Liquid Line Sizes for Various Lengths of Run

Recommended Vapor and Liquid Line Sizes for Various Lengths of Run

Equivalent Length to

Evaporator (ft)

Cooling Model

Liquid Line O.D. Sizes (in) Vapor Line O.D. Sizes (in)

6 7 10 11 12 15 20 6 7 10 11 12 15 20

0 to 15 1/2 1/2 5/8 5/8 5/8 5/8 7/8 1-1/8 1-1/8 1-3/8 1-3/8 1-3/8 1-5/8 1-5/8

16 to 50 1/2 1/2 5/8 5/8 5/8 5/8 7/8 1-1/8 1-1/8 1-3/8 1-3/8 1-5/8 1-5/8 1-5/8

51 to 100 1/2 1/2 5/8 5/8 5/8 3/4 7/8 1-1/8 1-3/8 1-3/8 1-3/8 1-5/8 1-5/8 2-1/8

101 to 150 1/2 1/2 5/8 5/8 5/8 3/4 7/8 1-3/8 1-3/8 1-5/8 1-5/8 2-1/8 2-1/8 2-1/8

NOTE: Line length between condenser and evaporator (suction and liquid) not to exceed 150' equivalent length.

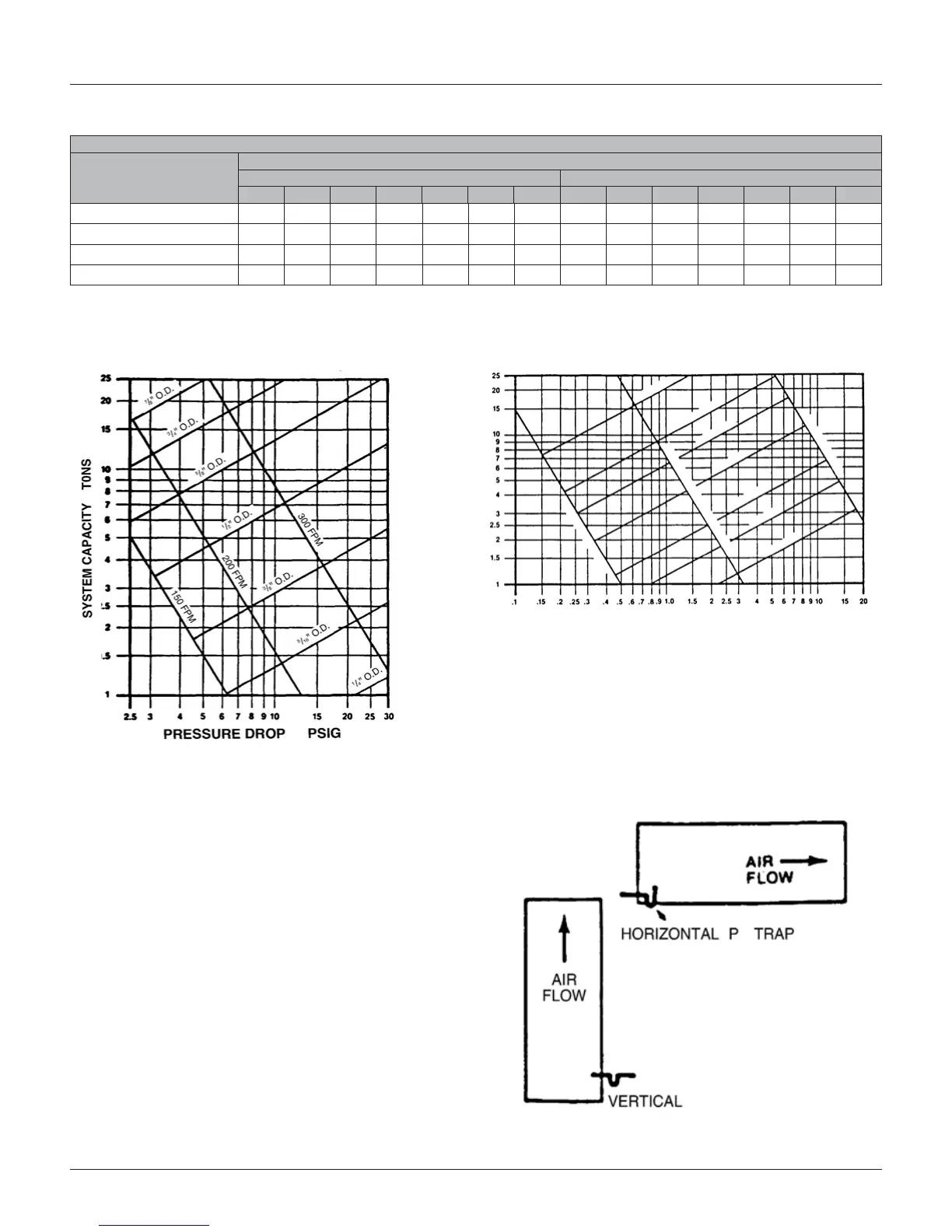

Figure 11: Liquid Line Pressure Drop Per 100 Feet

Equivalent Length (Type L Copper Tubing)

Note:

1. When evaporator coil is above condenser, the pressure

drop due to vertical lift (0.5 PSIG per foot of lift) must

be added to the pressure drop derived from this curve.

2. Size liquid line for no more than 10°F loss

(approximately 30 PSIG total pressure drop).

3. Do not oversize liquid line. Oversized liquid lines add

signicantly to the amount of refrigerant required to

charge the system.

4. The maximum recommended velocity with solenoid

valves or other quick closing devices in the liquid line is

300 FPM.

Figure 12: Suction Line System Capacity Loss In Percent

Per 100 Feet Equivalent Length (Type L Copper Tubing)

Note:

1. The minimum velocity line (700 fpm) is recommended

for cooling only units with vertical or horizontal run

refrigerant lines.

2. For suction pressure drop (PSIG), multiply percent (%)

loss by 1.18.

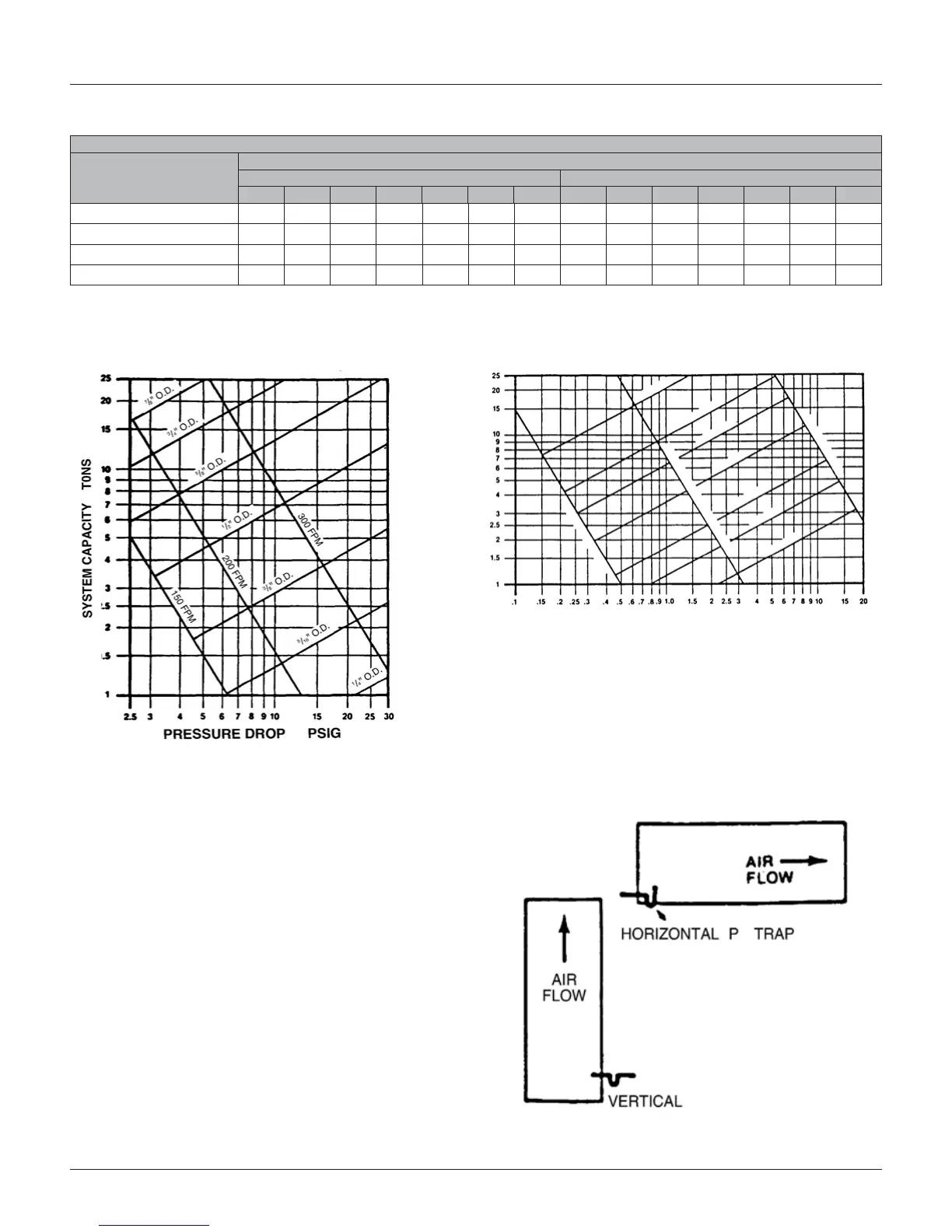

Figure 13: Typical Drain Piping

Loading...

Loading...