5 ■English

Outdoor Unit Installation

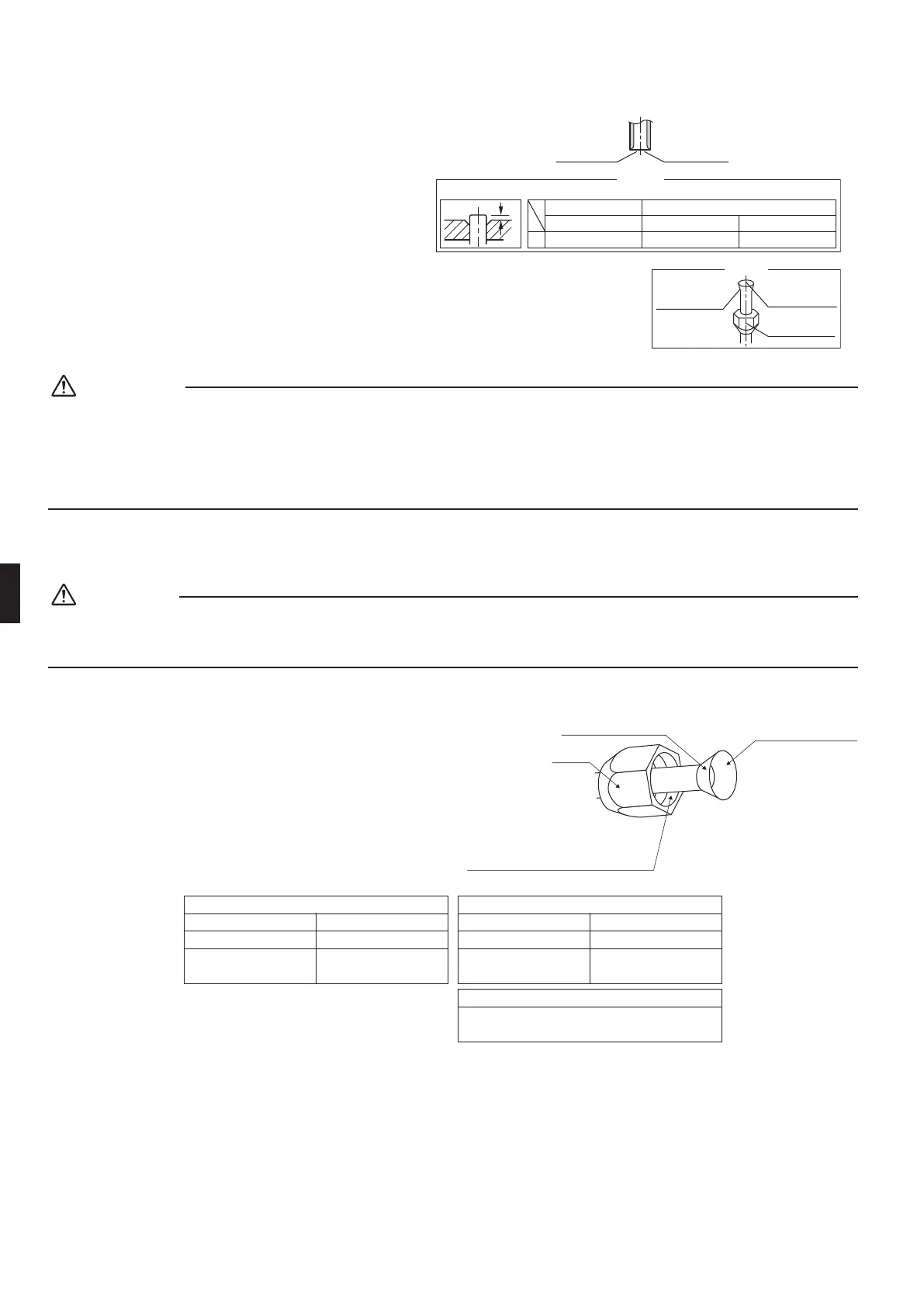

3. Flaring the pipe end

1)Cutthepipeendwithapipecutter.

2)Removeburrswiththecutsurfacefacing

downwardsothatthechipsdonotenterthepipe.

3)Putthearenutonthepipe.

4)Flarethepipe.

5)Checkthatthearingisproperlymade.

(Cut exactly at

right angles.)

Remove burrs.

Set exactly at the position shown below.

A

Flaring

Die

Check

Flare’s inner

surface must

be flaw-free.

The pipe end must

be evenly flared in

a perfect circle.

Make sure that the

flare nut is fitted.

A 0-0.5mm

Clutch-type

Flare tool for R410A

1.0-1.5mm

Clutch-type (Rigid-type)

1.5-2.0mm

Wing-nut type (Imperial-type)

Conventional flare tool

WARNING

•Donotusemineraloilonaredpart.

•Preventmineraloilfromgettingintothesystemasthiswouldreducethelifetimeoftheunits.

•Neverusepipingwhichhasbeenusedforpreviousinstallations.Onlyusepartswhicharedeliveredwiththeunit.

•DoneverinstalladriertothisR410Aunitinordertoguaranteeitslifetime.

•Thedryingmaterialmaydissolveanddamagethesystem.

•Incompletearingmaycauserefrigerantgasleakage.

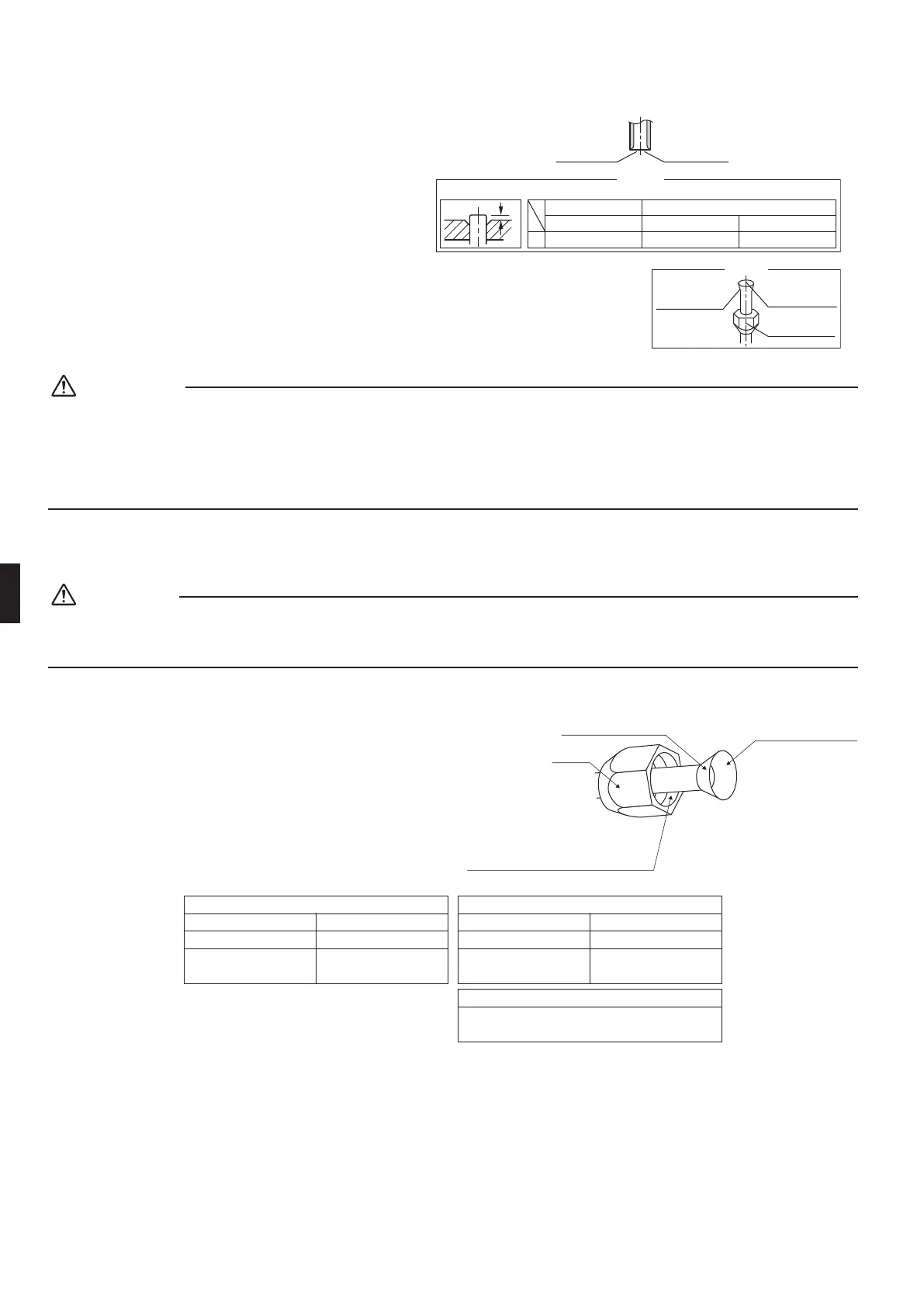

4. Refrigerant piping work

CAUTION

•Usethearenutxedtothemainunit.(Topreventcrackingofthearenutbyageddeterioration.)

•Topreventgasleakage,applyrefrigerationoilonlytotheinnersurfaceoftheare.(UserefrigerationoilforR410A.)

•Usetorquewrencheswhentighteningthearenutstopreventdamagetothearenutsandgasleakage.

•Alignthecentresofbotharesandtightenthearenuts3

or4turnsbyhand.Thentightenthemfullywiththetorque

wrenches.

Do not apply refrigeration

oil to the outer surface.

Flare nut

Apply refrigeration oil to

the inner surface of the

flare.

Do not apply refrigeration oil to the flare nut

to avoid tightening with excessive torque.

[Apply oil]

Flare nut tightening torque

Gas side Liquid side

3/8 inch 1/4 inch

32.7-39.9N • m

(333-407kgf • cm)

14.2-17.2N • m

(144-175kgf • cm)

Valve cap tightening torque

Gas side Liquid side

3/8 inch 1/4 inch

21.6-27.4N • m

(220-280kgf • cm)

21.6-27.4N • m

(220-280kgf • cm)

Service port cap tightening torque

10.8-14.7N • m

(110-150kgf • cm)

01_EN_3P297037-2D.indd 5 11/1/2012 11:04:42 AM

Loading...

Loading...