NOISE DIAGNOSIS

Noises generated by the accessory drive belt are

most noticeable at idle. Before replacing a belt to

resolve a noise condition, inspect all of the accessory

drive pulleys for contamination, alignment, glazing,

or excessive end play.

ACCESSORY DRIVE BELT DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

RIB CHUNKING (One or more ribs

has separated from belt body)

1. Foreign objects imbedded in

pulley grooves.

1. Remove foreign objects from

pulley grooves. Replace belt.

2. Installation damage 2. Replace belt

RIB OR BELT WEAR 1. Pulley misaligned 1. Align pulley(s)

2. Abrasive environment 2. Clean pulley(s). Replace belt if

necessary

3. Rusted pulley(s) 3. Clean rust from pulley(s)

4. Sharp or jagged pulley groove

tips

4. Replace pulley. Inspect belt.

5. Belt rubber deteriorated 5. Replace belt

BELT SLIPS 1. Belt slipping because of insuffi-

cient tension

1. Inspect/Replace tensioner if nec-

essary

2. Belt or pulley exposed to sub-

stance that has reduced friction

(belt dressing, oil, ethylene glycol)

2. Replace belt and clean pulleys

3. Driven component bearing fail-

ure (seizure)

3. Replace faulty component or

bearing

4. Belt glazed or hardened from

heat and excessive slippage

4. Replace belt.

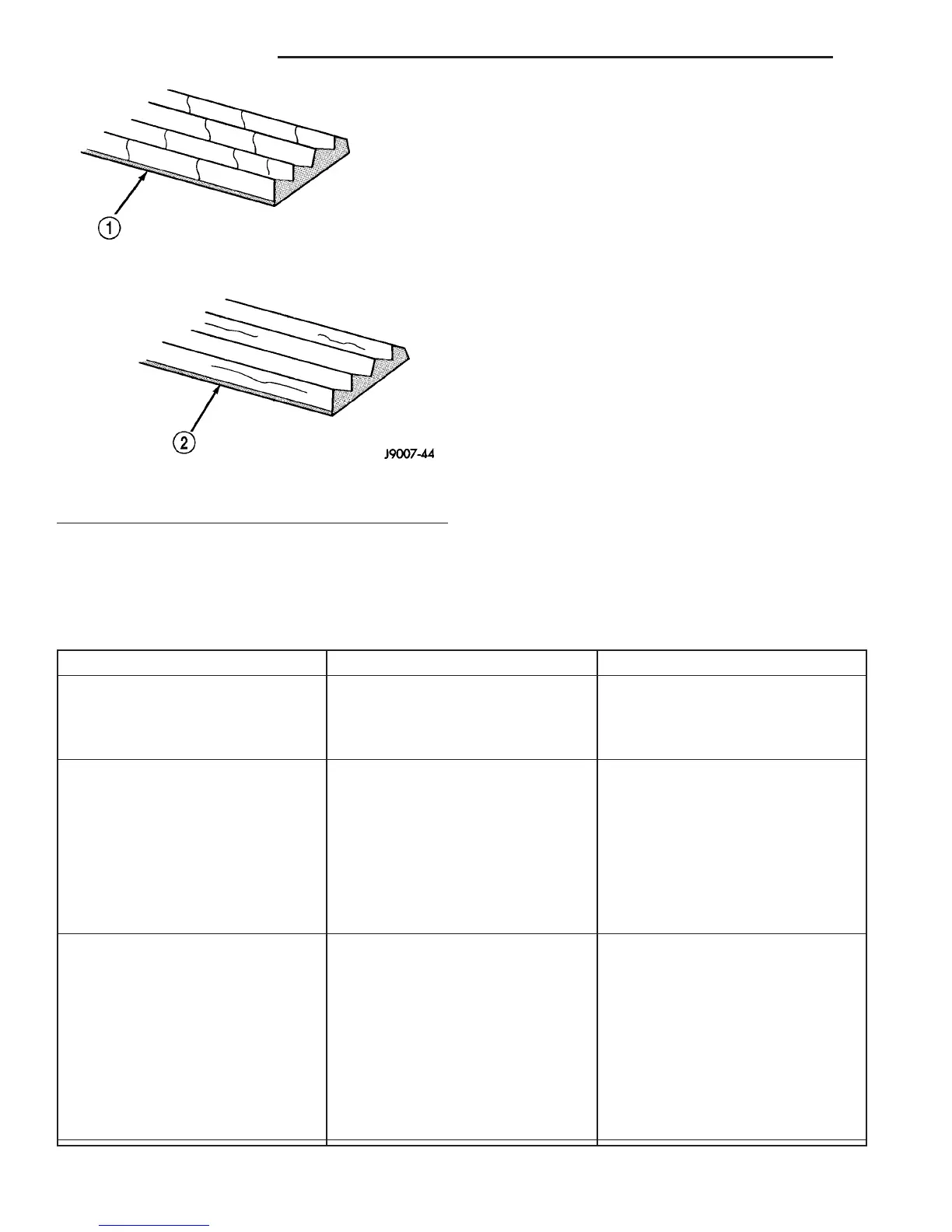

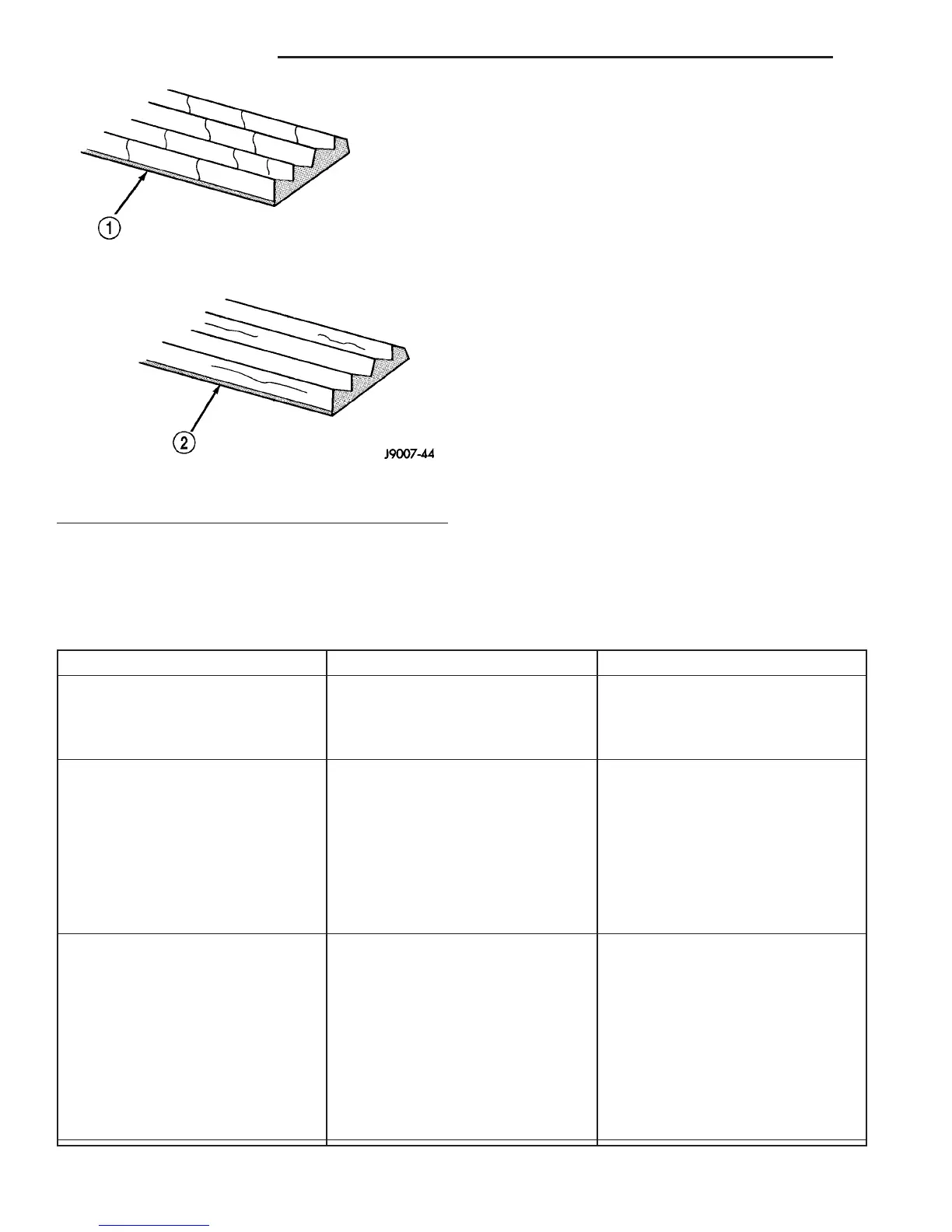

Fig. 2 Belt Wear Patterns

1 - NORMAL CRACKS BELT OK

2 - NOT NORMAL CRACKS REPLACE BELT

7 - 6 ACCESSORY DRIVE VA

Loading...

Loading...