6

180R9267 / IOM APP 1.5-3.5 Appendices - v04 / 11.2013

Data sheet APP pumps - APP 1.5-3.5

4

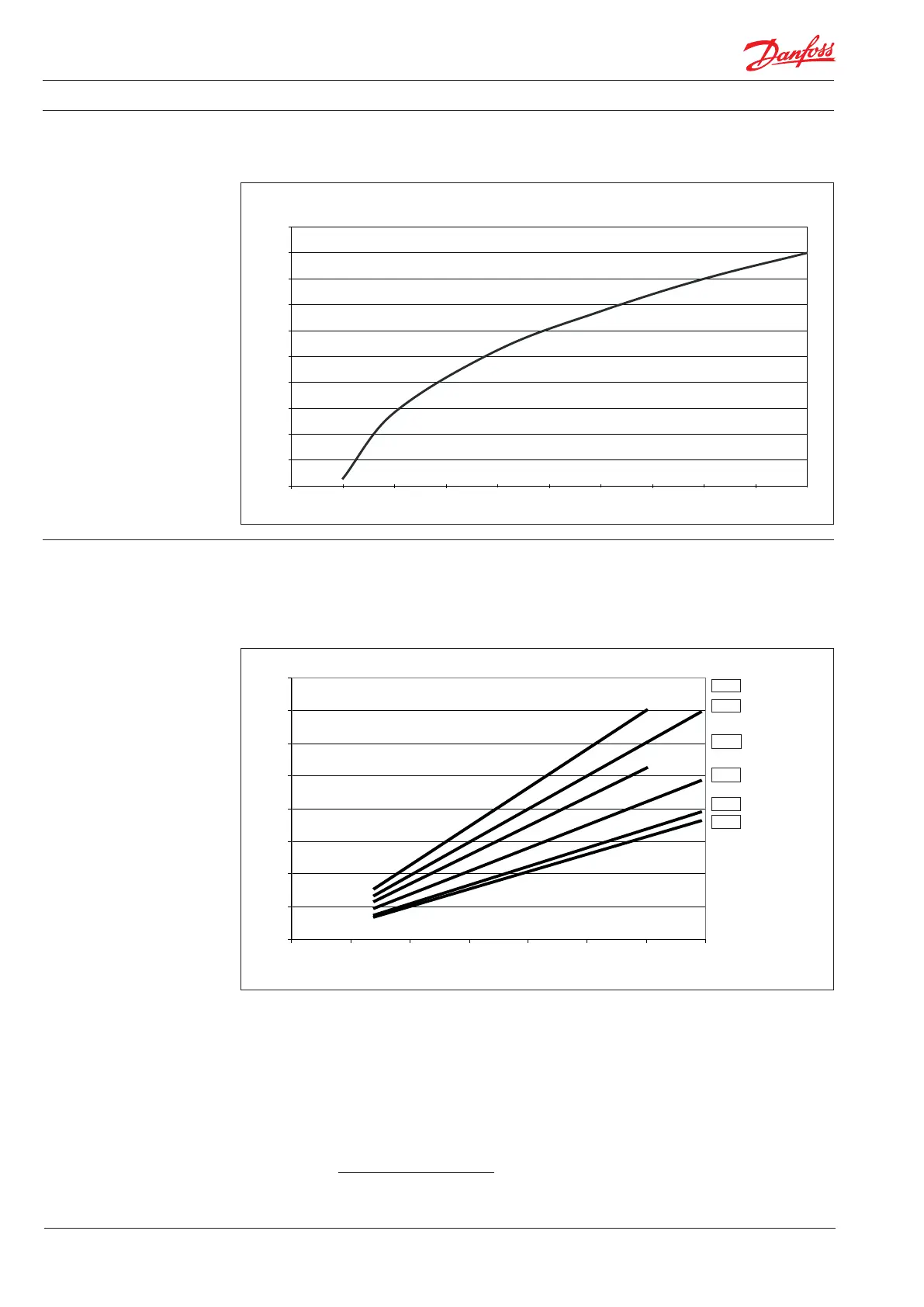

521B0850 / DKCFN.PD.013.FA6.02 / 09.2012

The diagram shows pressure dierences across

the ushing valve:

4. Flushing valve

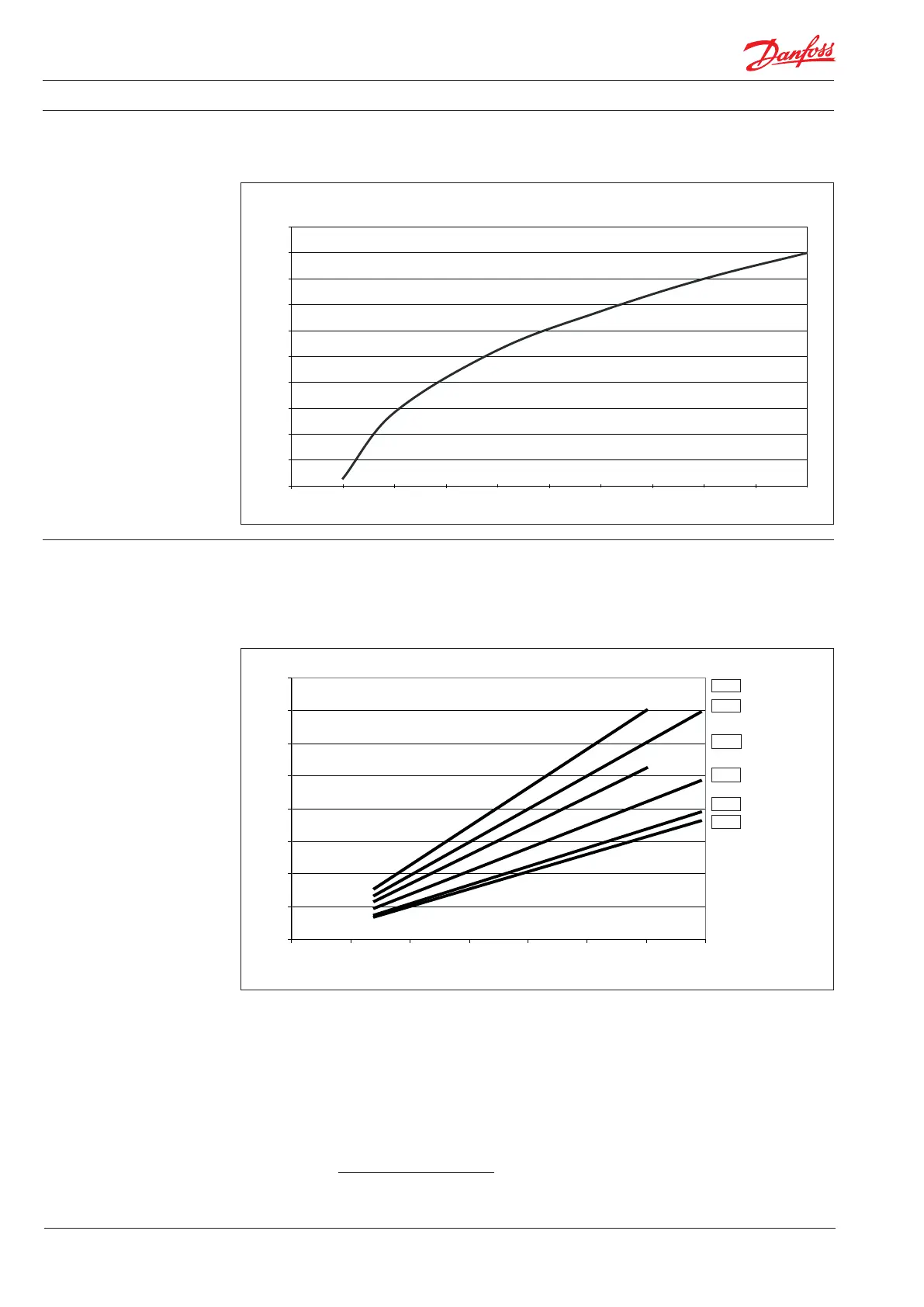

5. Flow at dierent rpm Using the diagram shown below, it is easy to

select the pump which ts the application best if

the ow required and the rotation speed (rpm) of

the pump are known.

Furthermore, this diagram shows that the ow

can be controlled by changing the rotation

speed of the pump. The ow/rpm ratio is

constant, and the “required“ ow can be

obtained by changing the rotation speed to a

corresponding value. Thus, the required rpm can

be determined as:

Required ow × Rated rpm

Required rpm =

Rated ow

521B0850 DKCFN.PD.013.FA6.02 3

5. Flow at diff erent rpm

Using the diagram shown below, it is easy to select the pump which fi ts the application best if the fl ow required and the rotation

speed (rpm) of the pump are known.

Furthermore, this diagram shows that the fl ow can be changed by changing the rotation speed of the pump. The fl ow/rpm ratio is

constant, and the “required “ fl ow can be obtained by changing the rotation speed to a corresponding value. Thus, the required rpm

can be determined as:

Required fl ow × Rated rpm

Required rpm =

Rated fl ow

6. Power requirements

Pump model Flow Pressure rpm Calc. factor

60 bar 70 bar 80 bar

l/min m

3

/h gpm 870 psi 1015 psi 1160 psi

APP1.5 25.11 1.51 6.63 3.21 kW 3.75 kW 4.29 kW 2890 468.6

APP1.5 30.17 1.81 7.97 3.86 kW 4.51 kW 5.15 kW 3470 468.6

APP1.8 26.78 1.61 7.07 3.43 kW 4.00 kW 4.57 kW 2890 463.2

APP1.8 32.18 1.93 8.50 4.12 kW 4.81 kW 5.49 kW 3470 463.2

APP2.2 33.48 2.01 8.84 4.29 kW 5.00 kW 5.71 kW 2900 468.6

APP2.2 40.22 2.41 10.63 5.15 kW 6.01 kW 6.87 kW 3480 468.6

APP2.5 41.94 2.52 11.08 5.07 kW 5.92 kW 6.77 kW 2900 484.8

APP3.0 48.2 2.9 12.7 6.2 kW 7.2 kW 8.2 kW 2930 470.0

APP3.5 56.0 3.4 14.8 7.2 kW 8.4 kW 9.6 kW 2930 470.0

The power requirements can be determined using one of the following guiding equations:

l/min × bar 16.7 × m

3

/h × bar 0.26 × gpm × psi

Required power = [

kW] or [kW] or [kW]

Calc. factor Calc. factor Calc. factor

1 hp = 0.75 kW

1 kW = 1.34 hp

1 gpm = 3.79 l/min

1 l/min = 0.26 gpm

1 m

3

/h = 4.40 gpm

1 gpm = 0.23 m

3

/h

0

0,5

1

1,5

2

2,5

3

3,5

4

0 500 1000 1500 2000 2500 3000 3500

rpm

m³/h

APP1.8

APP2.2

APP1.5

APP2.5

APP3.0

APP3.5

2 DKCFN.PD.013.FA6.02 521B0850

3. Technical data

APP pumps APP1.5 APP1.8 APP2.2 APP2.5 APP3.0 APP3.5

Code number 180B3043 180B3044 180B3045 180B3046 180B3030 180B3032

Geometric displacement

cm

3

/rpm

(in

3

/

rpm)

9.3

(0.56)

10

(0.61)

12.5

(0.76)

15.3

(0.93)

17.7

(1.08)

20.5

(1.25)

Rated fl ow (3000 rpm)

1)

m

3

/h

(gpm)

1.5

(6.6)

1.7

(7.5)

2.1

(9.2)

2.6

(11.4)

3.0

(13.2)

3.5

(15.4)

Outlet min. pressure

2)

bar

(psi)

20

(290)

20

(290)

20

(290)

20

(290)

20

(290)

20

(290)

Outlet max. pressure,

continuous

3)

bar

(psi)

80

(1160)

80

(1160)

80

(1160)

80

(1160)

80

(1160)

80

(1160)

Outlet max. pressure,

intermittent

4)

bar

(psi)

100

(1450)

100

(1450)

100

(1450)

100

(1450)

100

(1450)

100

(1450)

Inlet min. pressure

bar

(psi)

0.5

(7.3)

0.5

(7.3)

0.5

5)

(7.3)

0.5

(7.3)

0.5

5)

(7.3)

0.5

(7.3)

Inlet max. pressure,

continuous

bar

(psi)

5

(72.5)

5

(72.5)

5

(72.5)

5

(72.5)

5

(72.5)

5

(72.5)

Inlet max. pressure, peak

bar

(psi)

10

(145)

10

(145)

10

(145)

10

(145)

10

(145)

10

(145)

Max. speed continuous rpm 3450 3450 3450

5)

3000 3450

5)

3000

Min. speed continuous rpm 700 700 700 700 700 700

Power requirement

at 80 bar and 3000 rpm

kW

(hp)

4.5

(6)

4.8

(6.3)

6.0

(7.9)

7.2

(9.6)

8.4

(11.3)

9.8

(13.1)

Torque at 80 bar

Nm

(lbf-ft)

14,2

(10.5)

15.3

(11.3)

19

(14)

23

(17)

25.6

(18.8)

29.7

(21.9)

Weight

Kg

(lb)

8.6

(17)

8.6

(17)

8.6

(17)

8.6

(17)

8.6

(17)

8.6

(17)

Integrated fl ushing valve YES YES YES YES YES YES

1) Typical average fl ow at 80 bar (1160 psi). 4) Intermittent pressure is acceptable for less than

2) For lower pressure, please contact Danfoss RO Sales Organization.

10 seconds per minute.

3)

For higher pressure, please contact Danfoss RO Sales Organzation.

5) For speeds above 3000 rpm the pump must be

boosted at a pressure of 2-5 bar (29.0 - 72.5 psi).

4. Flushing valve

The diagram shows pressure diff erence across fl ushing valve

APP1.5-3.5 flushing valve characteristic

0

2

4

6

8

10

12

14

16

18

20

Pressure [bar]

Flow[l/min]

APP 1.5-3.5 ushing valve characteristic

Pressure [bar]

Flow [l/min)

20

18

16

14

12

10

8

8

4

2

0 1 2

2 3 4 5

Loading...

Loading...