11

180R9267 / IOM APP 1.5-3.5 Appendices - v04 / 11.2013

Data sheet APP pumps - APP 1.5-3.5

8

521B0850 / DKCFN.PD.013.FA6.02 / 09.2012

10.2 Complete unit

Pump A

(mm)

B

(mm)

C

(mm)

D

(mm)

E

(mm)

F

(mm)

G

(mm)

H

(mm)

IEC Electric motor

APP 1.5 250 260 100 160 140 325 120 166 3.0 kW, IEC 100L-2

APP 1.8 250 290 112 190 140 340 120 166 4.0 kW, IEC 112M-2

APP 2.2 300 338 132 216 140 403 144 166 5.5 kW, IEC 132S1-2

APP 2.5 300 338 132 216 178 403 144 166 7.5 kW, IEC 132S2-2

APP 3.0 350 422 160 254 210 505 188 166 11 kW, IEC 160M1-2

APP 3.5 350 422 160 254 210 505 188 166 11 kW, IEC 160M1-2

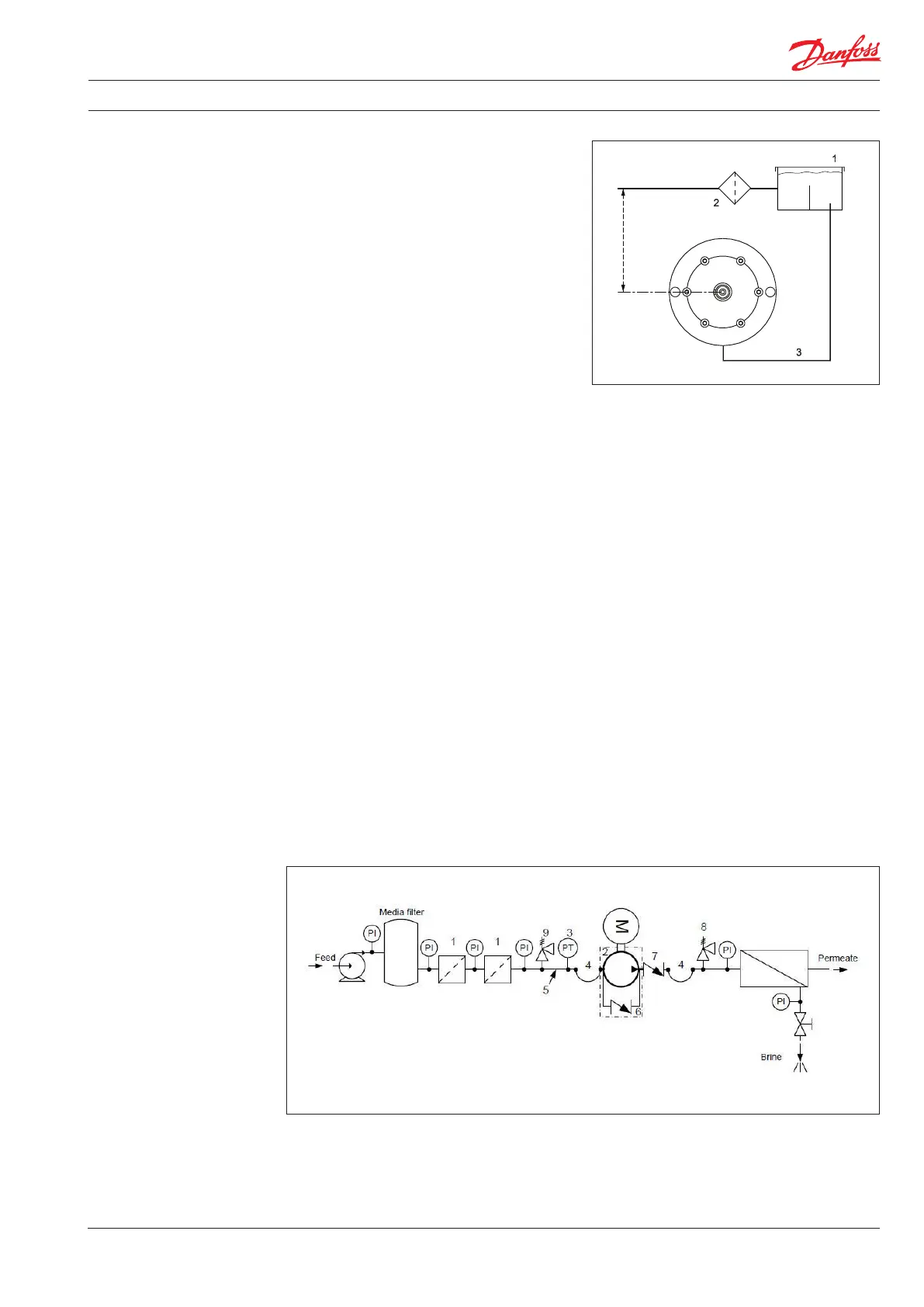

11. Installation 11.1 Mounting

The gure below illustrates how to mount the

pump and connect it to electric motor/combus-

tion engine.

A: Flexible coupling

B: Bell housing

C: Motor shaft

If alternative mounting is required, please

contact Danfoss Sales Organization for further

information.

To ensure easy mounting of the exible coupling

without using tools, the tolerances must be

dimensioned accordingly.

Note: Any axial and/or radial loads on the shaft

must be avoided.

The pump should be connected to the rest of the

plant with exible hoses.

A CB

Min. 5 mm

Data sheet APP pumps - APP 1.5-3.5

9

521B0850 / DKCFN.PD.013.FA6.02 / 09.2012

11.2 Open-ended system with direct water

supply

In order to eliminate the risk of cavitation, a

positive inlet pressure is always to be main-

tained. Please see technical data (part 3.) for

specic pressure values.

1. Place the lter (1) in the water supply line in

front of the pump.

2. Place a monitoring pressure switch (2) - set

at min. inlet pressure - between lter and

pump inlet. The monitoring switch must

stop the pump at pressures lower than min.

inlet pressure. Please see technical data

(part 3.) for specic pressure values.

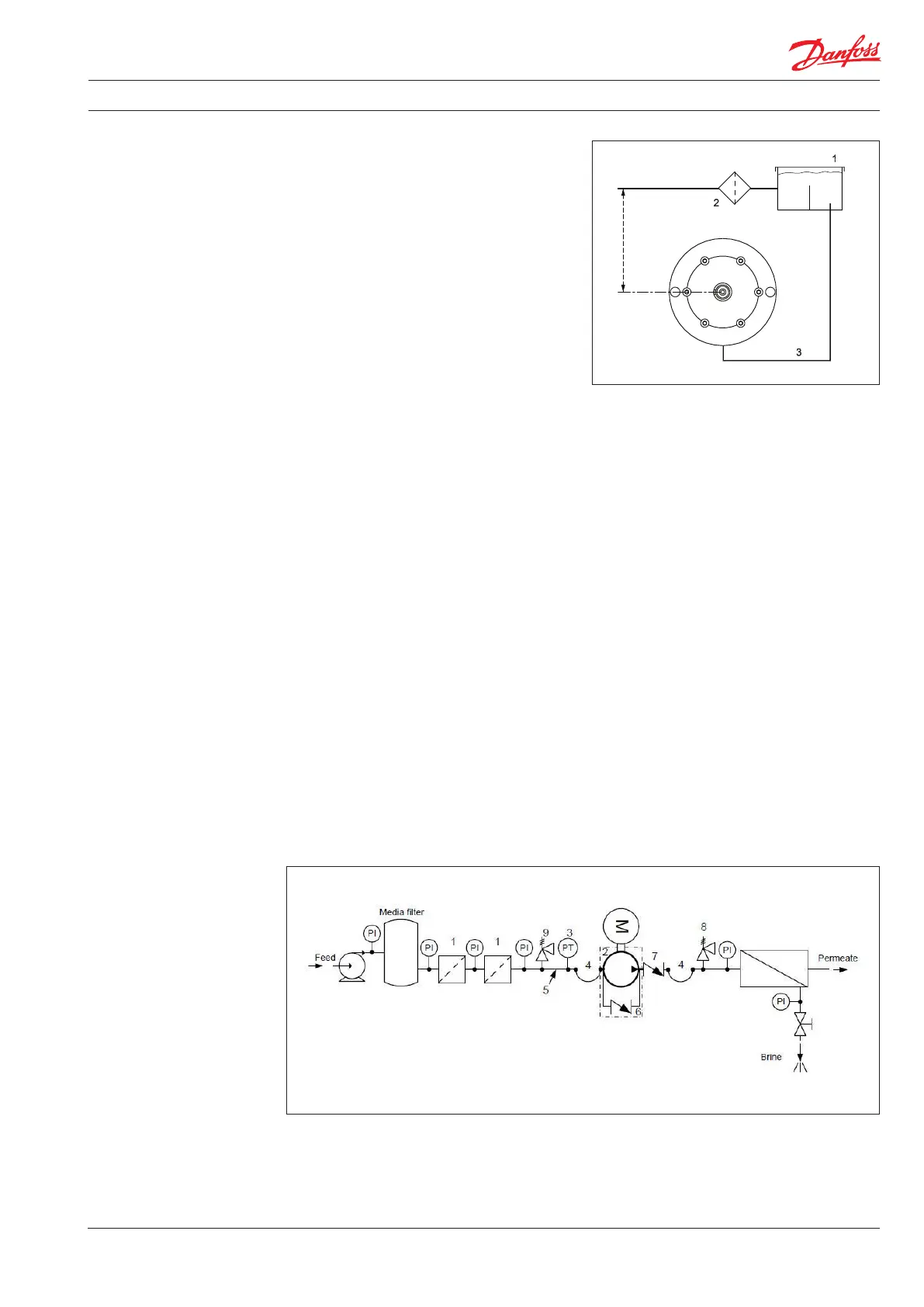

11.3 RO system with APP pump

1. Dimension the inlet line to obtain mini-

mum pressure loss (large ow, minimum

pipe length, minimum number of bends/

connections and ttings with small

pressure losses).

2. Place an inlet lter (1) in front of the APP

pump (2). Please consult section 9,

“Filtration” for guidance on how to select

the right lter. Thoroughly clean pipes and

ush system prior to start-up.

3. Place a monitoring pressure switch (3) set

at min. inlet pressure between lter and

pump inlet. The monitoring switch must

stop the pump at pressures lower than

minimum pressure.

4. Use exible hoses (4) to minimize vibrations

and noise.

5. In order to eliminate the risk of damage

and cavitation, a positive pressure at the

inlet (5) is always to be maintained at min.

inlet pressure and max. inlet pressure.

6. For easy system bleeding and ushing, a

bypass non-return valve (6) is integrated in

the APP pump.

7. A non-return valve (7) in outlet can be

installed in order to avoid backspin of the

pump. The volume of water in the

membrane vessel works as an accumulator

and will send ow backwards in case of the

pump stops momentarily.

8. A safety valve (8) can be installed in order

to avoid system damage as the Danfoss

APP pump creates pressure and ow

immediately after start-up, regardless of

any counter-pressure.

Loading...

Loading...