Setting

(se also “Wiring”)

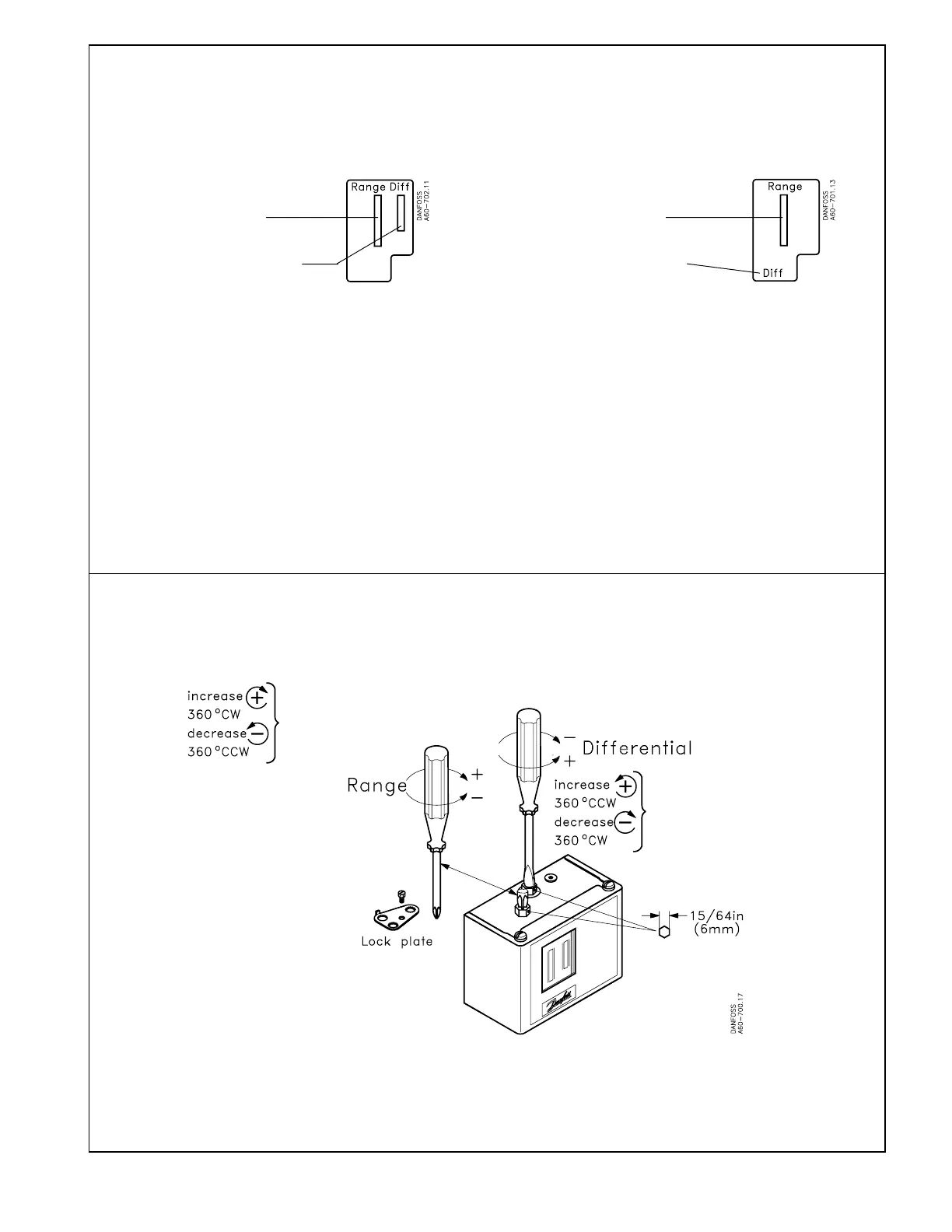

KP 1 (auto reset), KP 2, KP 5, KP 7W and KP 7B KP 1 (manual reset ONLY)

1. Adjust range spindle to desired 1. Adjust range spindle to desired

HIGH SET POINT (HSP) LOW SET POINT (LSP)

2. Adjust differential spindle to 2. DIFFERENTIAL is fixed.

desired DIFFERENTIAL (DIFF.) Value printed on scale plate

Note:

KP 5 (manual reset) and KP 7B have fixed diff.

Value printed on scale plate.

HIGH SET POINT minus DIFFERENTIAL equals LOW SET POINT LOW SET POINT plus DIFFERENTIAL equals HIGH SET POINT

Example: Example:

HSP – DIFF. = LSP LSP + DIFF. = HSP

30 psig – 20 psi = 10 psig 12 psig + 10 psi = 22 psig

(2.1 bar) (1.4 bar) (0.7 bar) (0.8 bar) (0.7 bar) (1.5 bar)

If terminals 1-4 are used: CUT-IN = HSP

CUT-OUT = LSP

If terminals 1-2 are used: CUT-IN = LSP

CUT-OUT = HSP

RI.5A.J1.22 © Danfoss A/S

10 psi (0.7 bar) /

rev. KP 1

7 psi (0.5 bar) /

rev. KP 2

33 psi (2.3 bar) /

rev. KP 5, 7W, 7B

3 psi (0.2 bar) / rev. KP 1

1.5 psi (0.1 bar) / rev. KP 2

4 psi (0.3 bar) / rev. KP 5

7 psi (0.5 bar) / rev. KP 7W

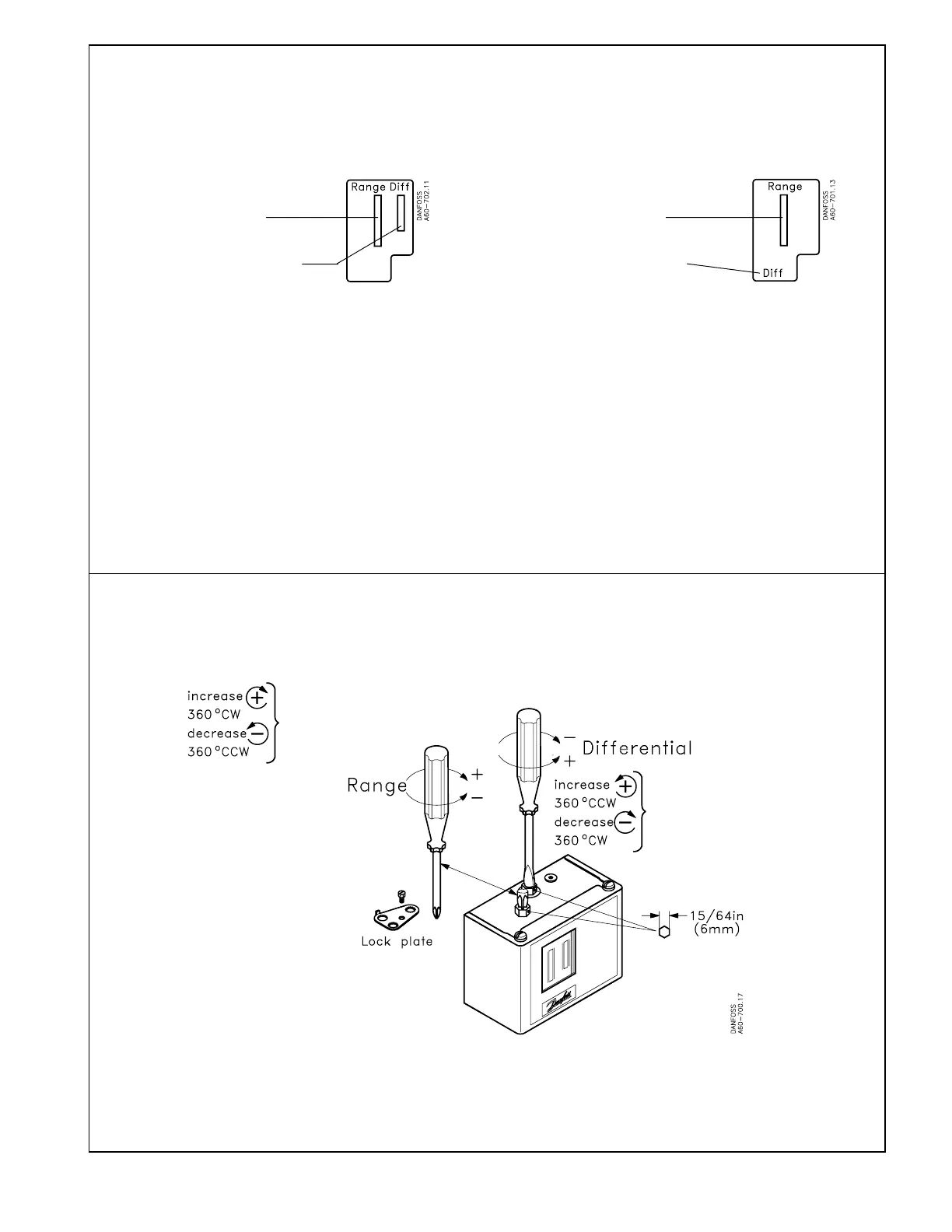

Adjustment

See instruction printed on top of control

Note:

Remove lock plate before adjustment.

Replace lock plate after adjustment (if desired).

Loading...

Loading...