8 Danfoss T-420 Crimp machine operator´s manual December 2022 8

Operating instructions

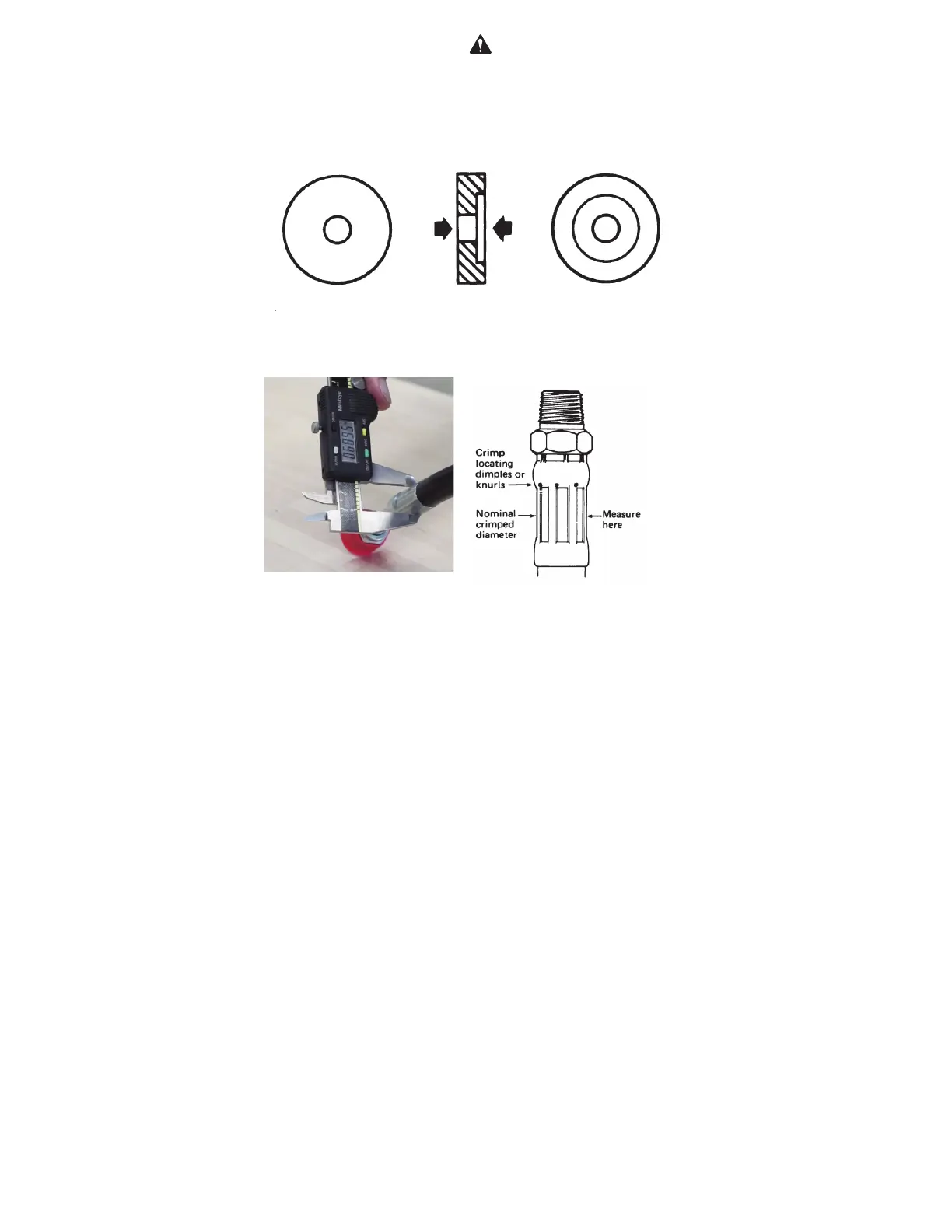

Spacer ring and nominal crimp

diameter measurement

Spacer ring

Typical spacer ring illustrating

both sides of ring

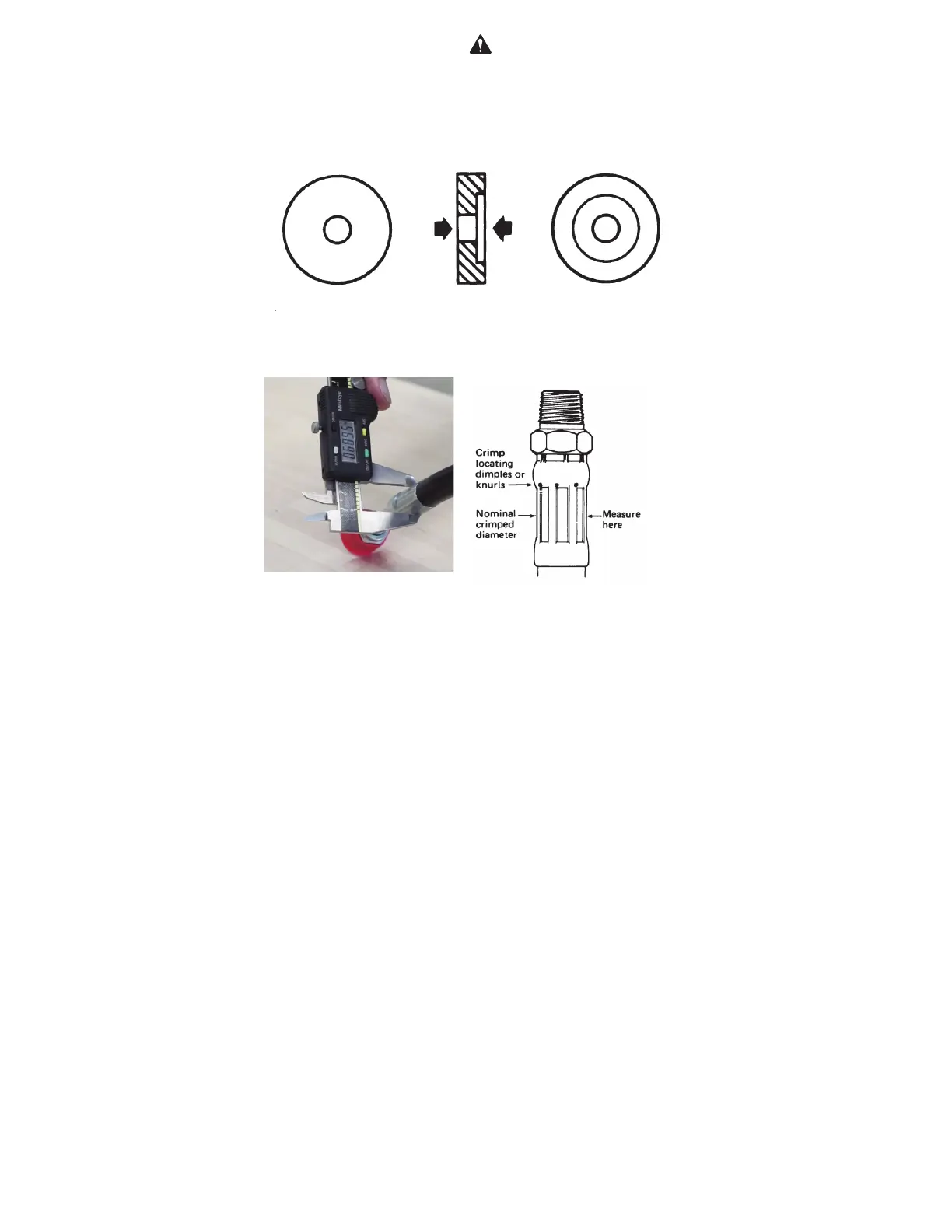

Nominal crimp diameter

measurement

Measuring crimp diameters

should be a part of the normal

hose assembly procedure.

To ensure a proper crimp

diameter reading, follow these

steps:

1. Measure the diameter in

the middle of the crimped

portion of the hose end.

2. Place the caliper in a

position to allow for a

measurement across the

pressed (flat) portion of the

crimp.

3. See crimp diameters in

crimp specifications.

Maintenance

Collet assembly lubrication

Every 30 crimps = Re-lubricate sliding surfaces of dies

Every 250 crimps = Remove old grease and re-lubricate

Base adapter ring lubrication

Every 250 crimps = Remove old grease and re-lubricate

Every 1,000 crimps = Remove old grease, inspect for

wear or damage and re-lubricate

if okay.

Flat side Counterbore side

Refer to safety information regarding Danfoss hose,

hose fittings, and assembly compatibility on page 2.

Loading...

Loading...