Class 121/ 122

IMPORTANT INSTRUCTIONS

Please read BEFORE using this model

Y

our model

c

o

nt

ains deli

ca

t

e p

r

ecision parts. Please handle ac

c

o

r

dingl

y.

R

em

o

ving

y

our model f

rom its

c

ase

:

R

em

o

v

e the model f

rom the pla

sc case along with its

f

oam packing.

The model

c

an then be

rem

ov

ed f

rom the

f

oam ab

o

v

e a so sur

f

ace t

o p

re

v

e

n

t dama

g

e if d

r

opped.

•

T

a

k

e

c

a

r

e

to ensu

r

e th

a

t d

e

t

ail parts do not

c

a

tch on the

f

oam as the model is

r

em

o

v

ed.

•

Do not use the Bu

ff

e

r

s or other parts as handles or l

e

v

e

r

s when

r

em

o

ving the model f

r

om its pac

k

aging.

Y

OUR MODEL NEEDS LIGHT

LUBRIC

ATION AFTER EVE

R

Y 50 HOU

R

S RUNNING:

•

Place a d

r

oplet of plas

c s

a

f

e oil o

nt

o a ha

r

d, non-a

b

sorbe

n

t, sur

f

ace;

•

Use a v

e

r

y fine poi

n

t

ed pai

n

tbrush

to t

r

an

s

f

er a v

e

r

y small amou

n

t of oil, p

r

ecisel

y

, ont

o the bearings

a

t the poi

n

ts indi

c

a

t

ed in the diag

r

am

o

v

erle

a

f. (The oil should not be pai

n

t

ed on but,

r

a

the

r,

c

apilla

r

y

acon should be used

t

o dr

a

w the nie

s

t amou

n

t of oil out of the p of the brush i

nt

o the bearing.)

•

D

r

y the pai

n

tbrush b

y blong with a

bsorbe

n

t paper, such as ki

tchen

t

o

w

el;

•

R

e-apply the d

r

y pai

n

tbrush o

nt

o the oiled bearin

g,

to ‘wick

aw

a

y

’ a

n

y

e

x

cess oil.

R

epe

a

t

ste

p

s 3 and 4

u

n

l the only

r

emaining oil is an

e

xt

r

emely fine (almo

s

t invisible)

co

a

ng

a

t the p

r

ecise poi

n

t wher

e the

t

w

o

compone

n

ts rub

t

o

g

ethe

r

.

Please

k

eep oils and lubri

c

a

n

ts

aw

a

y f

r

om the Mo

tor and elect

r

onic ci

r

cuit

r

y lo

c

a

t

ed inside the bod

y.

The mo

t

or is of ad

v

anced sel

f

-lubri

c

a

on design,

‘

sealed

-f

o

r

-li

f

e

’

, and lubri

c

a

n

ts m

ay dama

g

e the deli

c

a

t

e

ci

r

cuit

r

y

. Als

o

, be

aw

a

r

e th

a

t N

g

au

g

e t

r

ack should n

e

v

er be laid di

r

ectly ont

o

c

arp

e

t, as du

s

t and fib

r

es will

become e

nt

angled in

y

our lo

comove’s finely d

et

ailed mechanisms.

*Y

our model supplier

c

an advise on the be

s

t ‘pla

s

c s

a

f

e’ oils and lubri

c

a

n

ts

av

ailable in

y

our

cou

n

t

r

y.

Y

ou will ob

tain qui

et

er and smoother per

f

ormance f

r

om

y

our Dapol lo

como

v

e if

y

ou i

nv

e

s

t a lile me

‘running in’ the mo

t

or and the moon parts.

W

e

r

e

commend th

a

t

y

ou begin the ‘running in’ period

b

y

ope

r

a

ng the lo

como

v

e on its

o

wn,

a

t a mode

r

a

t

e speed,

f

or a period of

a

t leas

t half an hour in each

di

r

econ. (The

compl

e

t

e

‘

s

eling in’ p

r

ocess oen

co

n

nues be

y

ond the inial ‘running in’ period, and

y

ou will noce th

a

t the lo

como

v

e g

r

adually runs qui

et

er and smoother

o

v

er s

e

v

e

r

al

wee

k

s of normal

c

oach/

w

a

gon hauling ope

r

a

on.)

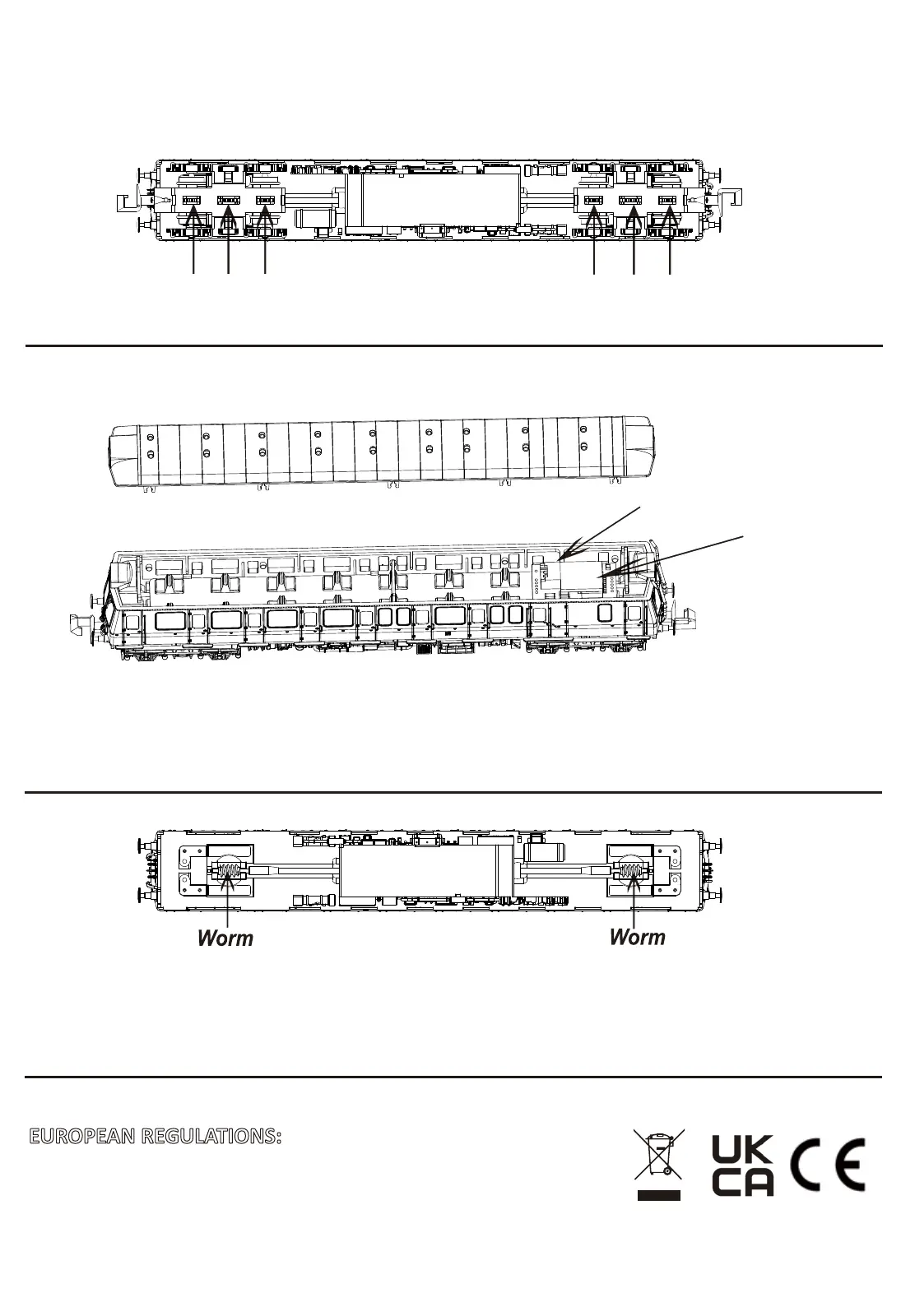

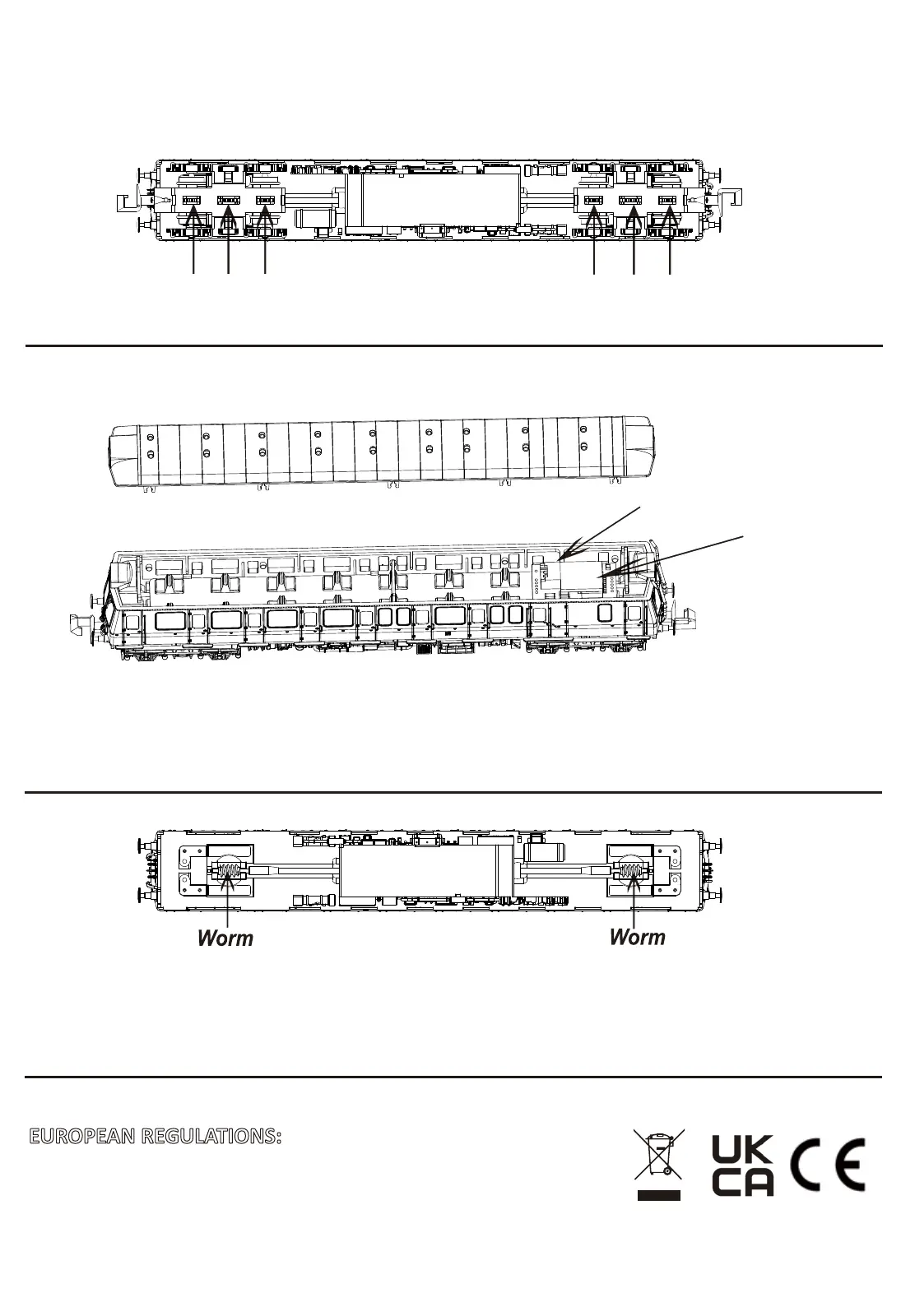

Class 121

Oiling points for gears before test running,

and removal of body for DCC installation

DC OPERATION:

If you wish to run the model on standard DC – then do nothing. Our PCB will automacally recognise that

you have DC controller and will allow operaon at normal DC parameters. Important Note: This model

should only be used with a DC controller designed for model railways rated at 12V DC nominal voltage.

(oponally) fied with an appropriate DCC decoder it may also be used with a compable DCC

When

control system. You can turn the rear light off by pulling the DIP switch to the 'OFF 'posion.

DCC OPERATION:

Our model is fully DCC ready. The model is fied with a DCC board which features a Next 18 plug pre-fied

with a ‘blanking plug’. Carefully remove the blanking plug and insert the decoder of your choice. Before

converng to DCC please ensure that your decoder will fit the model, as some decoders are large and

could have a thick protecve outer shroud. To expose the PCB, simply pull the body away from the chassis

using finger pressure. Fit your decoder and programme as normal. Reclip the body.

We have designed this model to have independent control of front and rear lamps. For best operaon, we

recommend a 4 funcon (or greater) decoder is fied (for example a 6 funcon Dapol Imperium Next-18)

to your model. If you have purchased the Dapol factory fied decoder it has been fied with a

pre-programmed Imperium decoder (Please refer to separate DCC operaon instrucons supplied). If

fing a decoder (including a non-factory fied Imperium) you will need to consult the decoder manual to

correctly configure the decoder for operaon of the locomove lighng.

For reference, the model’s lighng assignments are below:

Decoder output Front light (FLf) Rear Light (FLr) AUX 1 AUX 2 AUX 3 AUX 4

Lighng Front white lamps Front red lamps Rear white lamps Rear red lamps No connecon Light bar (oponal)

EUROPEAN REGULATIONS:

To expose drive worms and chassis for roune maintenance, simply pull the complete

bogie assembly away from the chassis. The bogies are a ‘pull out ’ & ‘push in ’ fing

method. When refing, ensure that the gear on top of the bogie tower meshes with

the worm.

To remove roof, simply pull roof away from body to leave exposed body as image.

Normal oiling points into exposed gears without removing body

Made in China

WARRANTY:

Please refer to separately provided warranty paperwork for details.

RUNNING IN’ YOUR LOCOMOTIVE:

UNPACKING & HANDLING YOUR LOCOMOTIVE:

Dapol products conform to WEEE and RoHS requirements.

If you have a need to dispose of any electrical part, please do so correctly.

DC Blanking Plug

ACCESSORY PARTS:

•

•

Dummy Screw Coupling:

This is clipped into the hook already placed on the buffer beam.

Pipes

: Are fied in the order shown and push into matching openings in the buffer beam.

If desired a small spot of adhesive can be used to secure.

Addional detail parts are supplied in plasc bags within the outer case & fied as follows:

• Couplings can be removed or supplied alternaves fied by simply pulling the exisng

Rapido type away from the locomove. Alternaves simply push fit.

Please note that the following parts may interfere if a coupling is fied.

Decoder CV programming informaon:

To enable two buon control of lighng (F0 = #1 end, F1 = #2 end), the NMRA standard CV programming is:

CV33 = 5, CV34 = 6, CV35 = 10, CV36 = 9, CV51 = 24, CV52 = 0. This is the default seng for factory fied

decoders and will require to be re-programmed in this way if a full decoder factory reset is performed.

An extremely light applicaon of plasc safe * oil, such as Dapoil or Locolube before running in your

model is required, followed by maintenance oiling aer every 50 hours of running me. (Storage in hot

environments may require more frequent applicaons). Please be aware that over-oiling the wheel

bearings will interfere with the electrical pickup of your model. Therefore, we recommend you use a very

fine arst’s paintbrush to apply only the niest amount of lubricang oil precisely between the bearing

surfaces, as follows:

LIGHT BARS:

This model is "Light Bar Ready". The Dapol Light Bars operate on both DC and DCC power

without any external modificaon. Instrucons for fing Dapol Light Bars are contained

within the packaging of the Light Bar packs.

Light Bar Socket

Loading...

Loading...