6 7

Evaporative coolers, RO lters and extra draw-off capacity

Where a Torrium2 equipped pump is required to supply water to an evaporative cooler,

reverse osmosis (R.O.) lter or similar low ow device, the Torrium2 will detect the

limited demand. This will result in the Torrium2 adapting to the slow demand. The

pump start pressure will be allowed to drop to a lower cut in pressure each time low

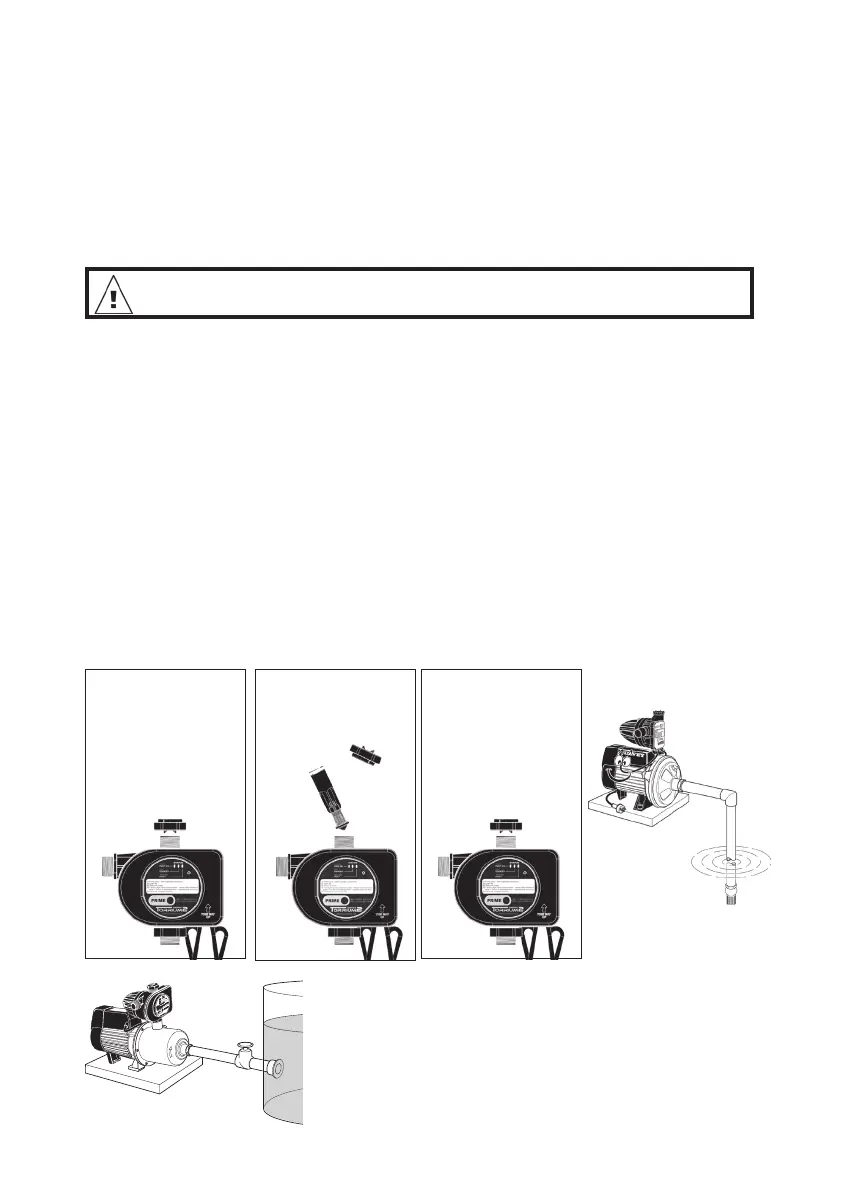

ows are detected. To provide the maximum draw-off from the additional pressure tank,

the tank’s pre-charge should be set at 45% of the pump shut-off pressure.

If normal ow is required from your system, Torrium2 will initiate instant start.

Fit the pressure tank downstream of the controller.

DO NOT USE THREAD SEALING COMPOUNDS, HEMP OR PIPE DOPE!

Where to use Check Valves and Foot Valves

The Torrium2 controller tted to BT Boosters has an inbuilt non-return (check) valve tted.

In ooded suction installations there is no need to have a suction non-return valve.

In some suction lift installations there may be good reason to modify the inbuilt

check valve to ensure that the discharge pressure is also applied to the suction line

and footvalve. This could be where the suction line was very long or where there

was concern regarding a leaking footvalve. This may not always be applicable and

it is acceptable to retain the inbuilt check valve in the Torrium2 on suction lifts with

good suction plumbing.

Should the inbuilt check valve be required to be modied though, an additional

accumulator should be tted to the discharge pipework, to ensure the pump is not

cycled on shut down. The size of this accumulator will depend on the size, length

and type of pipe used on the suction.

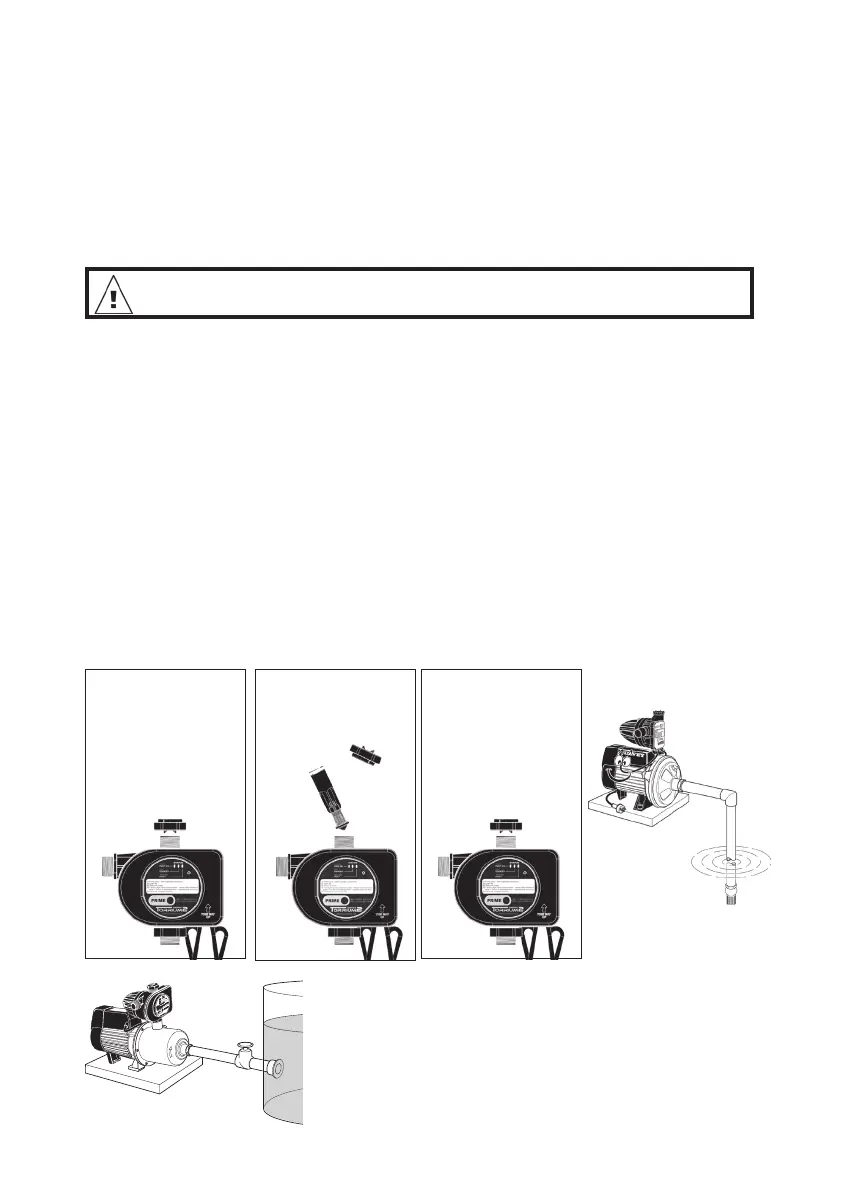

To modify the check valve for suction lift conditions, follow these simple steps: ➞

Torrium2 Check Valve Removal

Installations with ooded suction require

a gate or isolating valve so water supply

can be turned off for pump removal and

servicing.

1. Remove priming

cap and turn over

cap. Lugs on cap

will engage check

valve to unscrew

4. Tighten check

valve using

inverted priming

cap and replace

priming cap

2. Roll off o-rings

3. Re-install check

valve

Loading...

Loading...