- 5 -

Installation

All motors must be installed in such a manner as to ensure

the air intake is not obstructed. Bed plates or slide rails should

be rmly xed to a solid, level foundation to ensure the motor

remains rigid and vibration free. Shims or packers (if required)

must be of adequate size and placed adjacent to and between

base xings.

Operation

Standard motors are designed for a 415 volt (±5% ) 3 phase,

50 Hertz supply. Use of standard motors on other supply

systems should be veried with our ofce prior to installation.

All units are S1 rated to AS1359 and associated standards,

for operation below 1000 metres at a maximum ambient

temperature of 40°C.

For operation in conditions other than that above please

contact Davey.

Electric motor starting imposes severe thermal stress on

the motor, the frequency of starting should be minimized to

ensure optimum machine life.

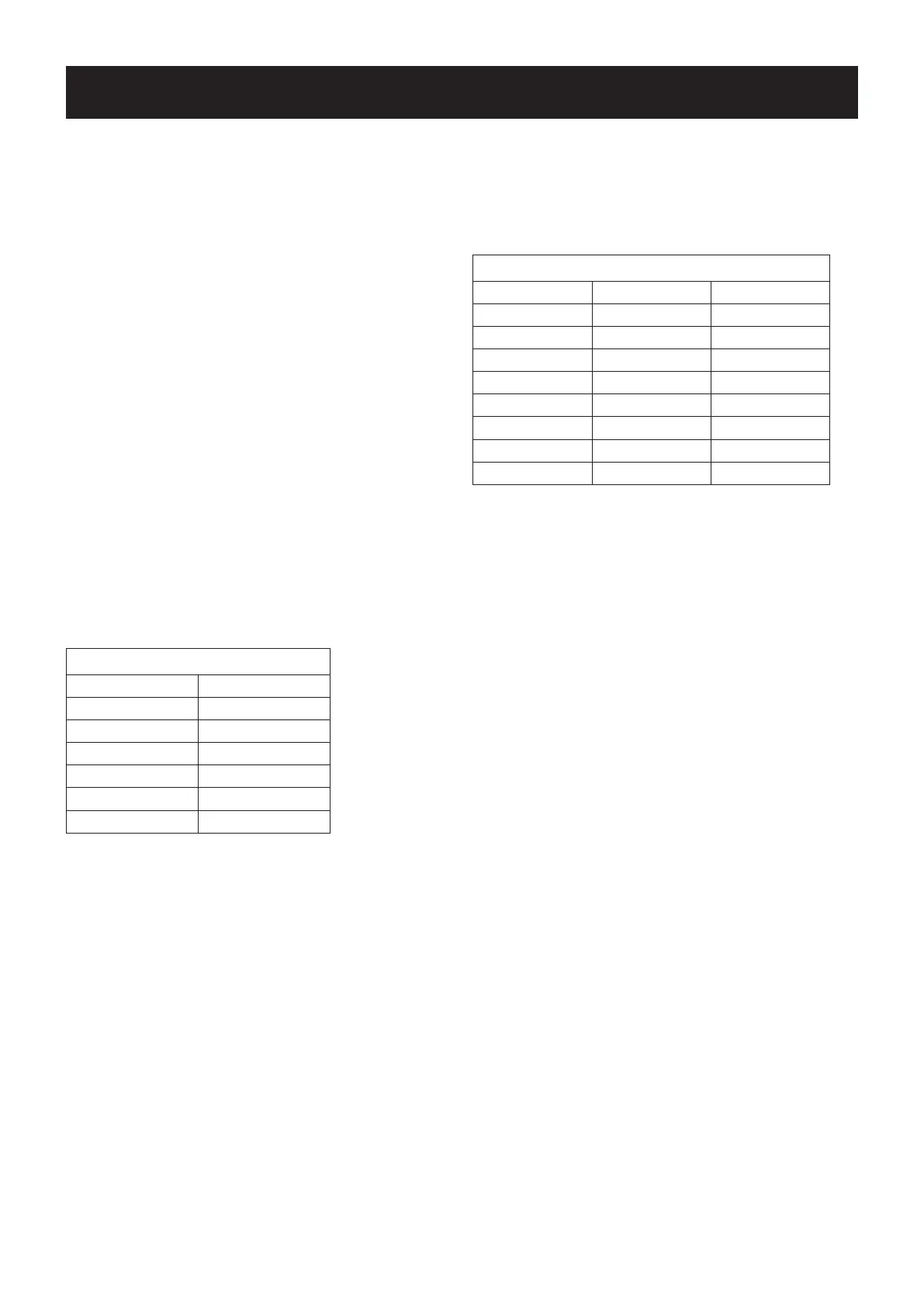

Number of Starts per hour

The number of starts per hour is dependant on the inertia

of the driven load and the load torque demand. A guide to

generally acceptable starts per hour would be as per table.

For greater number of starts per hour, please contact Davey.

STARTS PER HOUR

Frame 2 pole

90 16

100 16

112 16

132 10

160 10

180 8

MOTOR OPERATION AND MAINTENANCE

Permitted Starting Time

In respect to the temperature rise of the motor, starting time

(i.e. from rest to operational speed) should not exceed the

time indicated in the following table. Motor must be allowed to

cool prior to each start.

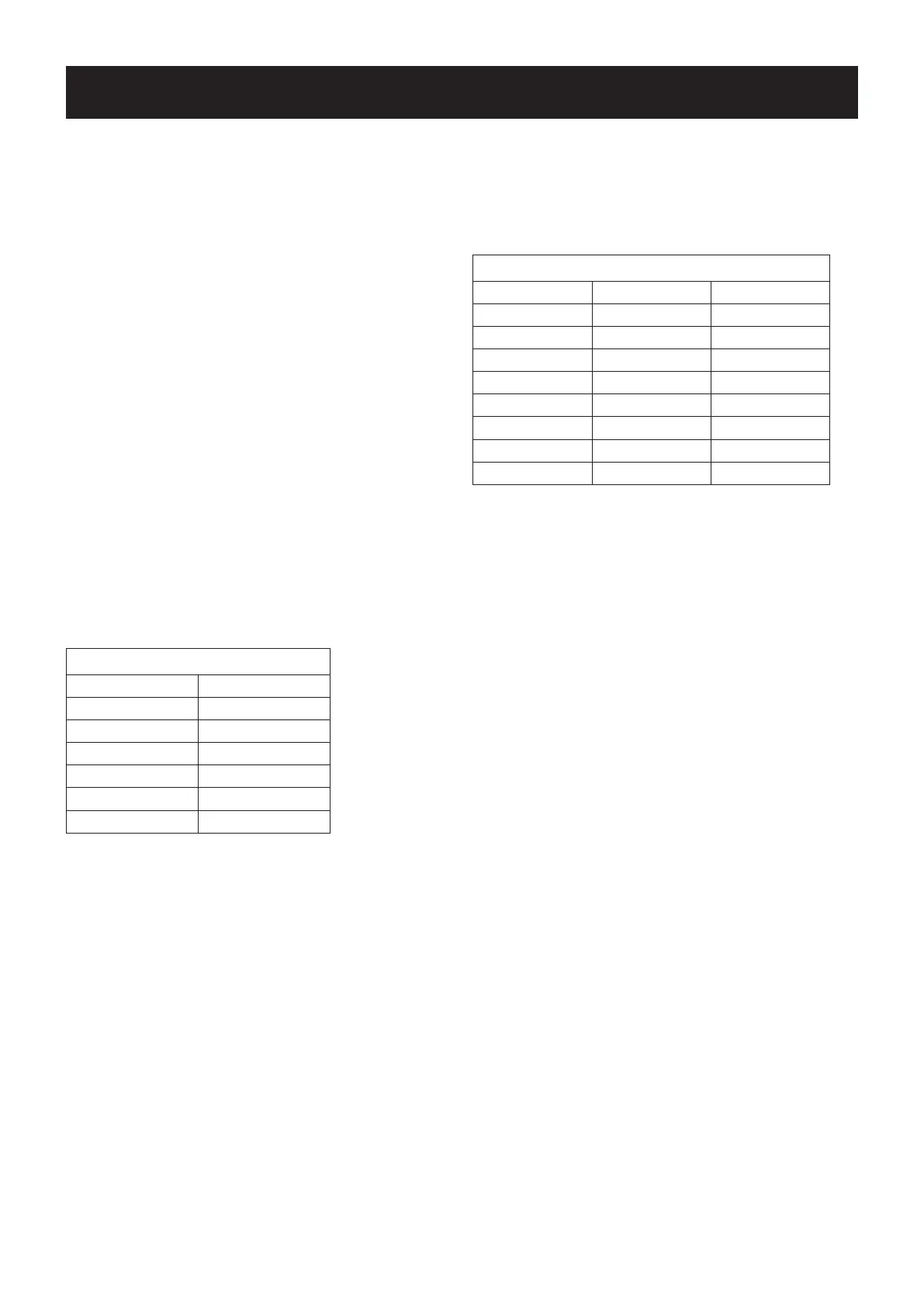

MAXIMUM STARTING TIME (SEC)

Frame Starting Method 2 pole

71 D.O.L. -

80 D.O.L. 15

90 D.O.L. 10

100 D.O.L. 12

112 D.O.L. 10

132 D.O.L. 14

160-355 D.O.L. 15

160-355 star-delta 45

Maintenance

To avoid damaging the mechanical seal, do not operate the

pump without water in the pump casing. If the supply water is

interrupted stop the pump immediately.

Do not set the water ow by partially closing off the suction

valve as restricting the supply water can cause cavitation and

severely damage the pump’s components.

If the pump makes strange noises or vibrates, stop the pump

and check for the cause/s.

It is not advisable to start and stop the pump frequently. If the

power is interrupted during operation, turn the power switch

off immediately.

If the pump is to remain inactive for a long period of time,

wash the pump body and drain the water out of the pump

casing completely.

When the air temperature drops below 0°C, drain the water

from the pump casing as soon as it nishes operating.

Loading...

Loading...