12

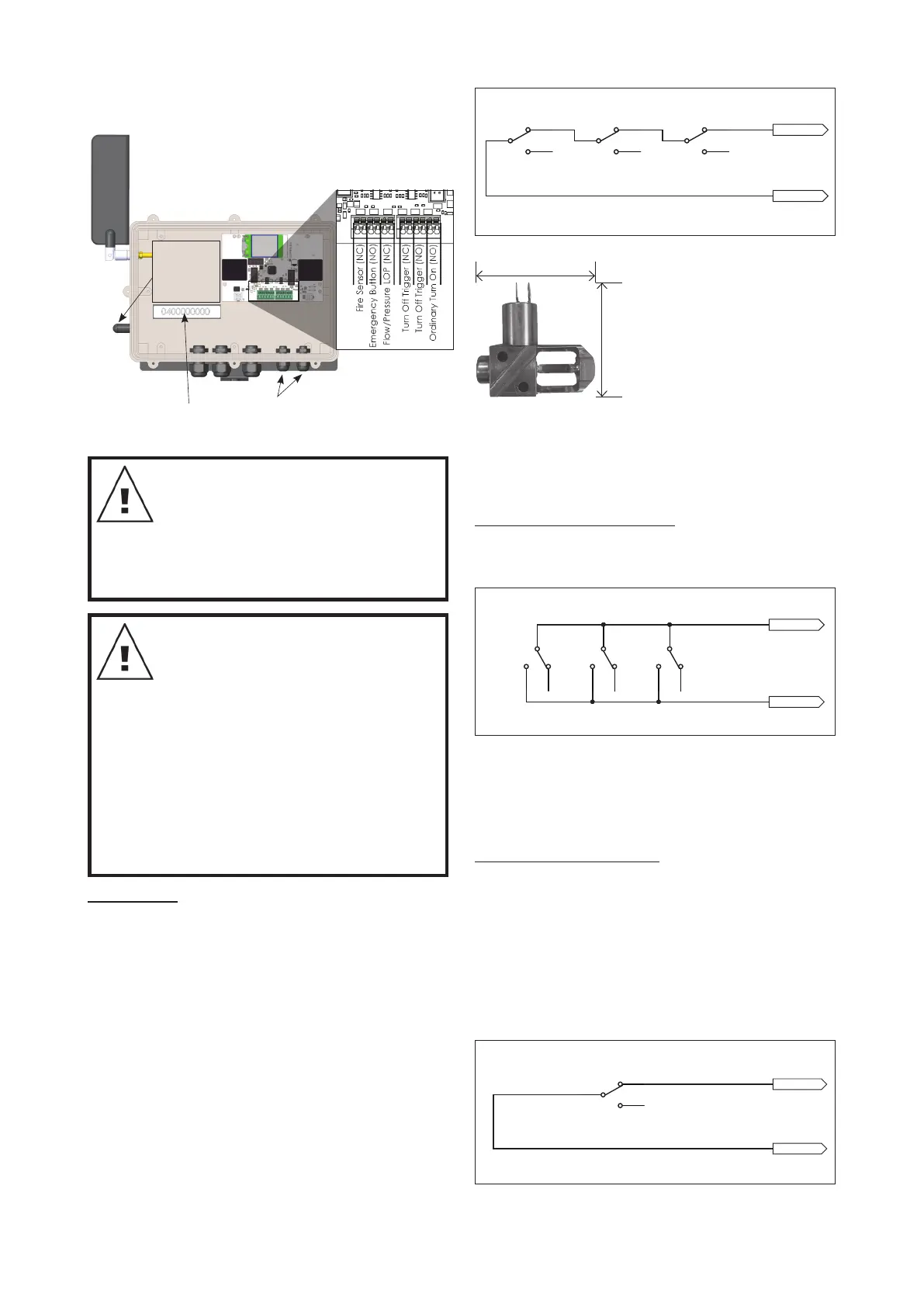

7.8 Auto/Remote Control Centre with

Cover Removed

Mobile Phone

Number

Access grommet

for re sensor/s or

external sensors

Speed Setting

Switch

UP = high speed

DOWN = low

speed

Figure 7.3

NOTE: To allow for automatic or

remote starting (e.g. by SMS) the

keystart must be left in the “ON”

position. Operation via SMS is only

possible where your pump Remote/

Auto Control Centre is within

reception range.

WARNING: Always disconnect battery

from engine prior to working on pump,

engine, or controller. Turning the key

start switch to “OFF” may allow a

remote start signal to enable engine

“cranking”, but not starting.

The black battery lead should be

connected to the negative terminal

(-ve) on the battery. Only once ready,

including after all necessary external

wiring connections are complete,

should the red lead be connected to the

positive terminal (+ve) on the battery.

Fire sensors: (Davey part number 402939). These

must be connected in series. The looped wiring is

connected to the Fire Sensor (NC) terminal and the

adjacent “GND“ terminal inside the Remote/Auto

Control Centre. The bridging wire included must be

removed if the re sensors are installed.

The wire used to connect the sensors should be

suitable for extra low voltage usage in the outside.

Wiring such as is used for automatic irrigation

control valves is ideally suited. Sizes 7/0.30 or

7/0.43 are more than sufcient for the purpose.

These should be protected from damage as an

open circuit (e.g. broken or cut wire) will result in

automatic pump start.

Sensors should be mounted on the edges of the

building or the property to be protected every 10

to 20 metres. The connecting wire must be in one

continuous loop.

2

3

1

2

3

1

2

3

1

Normally closed, stay on when open - only SMS can turn off

Fire Sensors

Input 1

GND 1

2

3

1

Normally open, stay on when closed - only SMS can turn off.

Emergency Button(s)

Input 2

GND 2

2

3

1

2

3

1

Normally open, turn on when closed,

off when open or Pressure or Float or LOP.

Ordinary Turn On Switch

Input 6

GND 6

2

3

1

2

3

1

At turn on, check closed within 4 minutes - otherwise LOP fault

Flow/Pressure LOP Switch

Input 3

GND 3

Once running, if opens fault after 30 seconds Bridge if not used.

Normally open, turn off when closed.

Float Turn-off

Input 5

GND 5

2

3

1

2

3

1

Normally closed, turn off when opened Bridge if not used.

Pressure Switch Turn-off (Tank or Shut-head)

Input 4

GND 4

Bridge if not used.

Normally open, run low speed when closed.

Speed Input

Input 7

GND 7

2

3

1

Figure 7.4

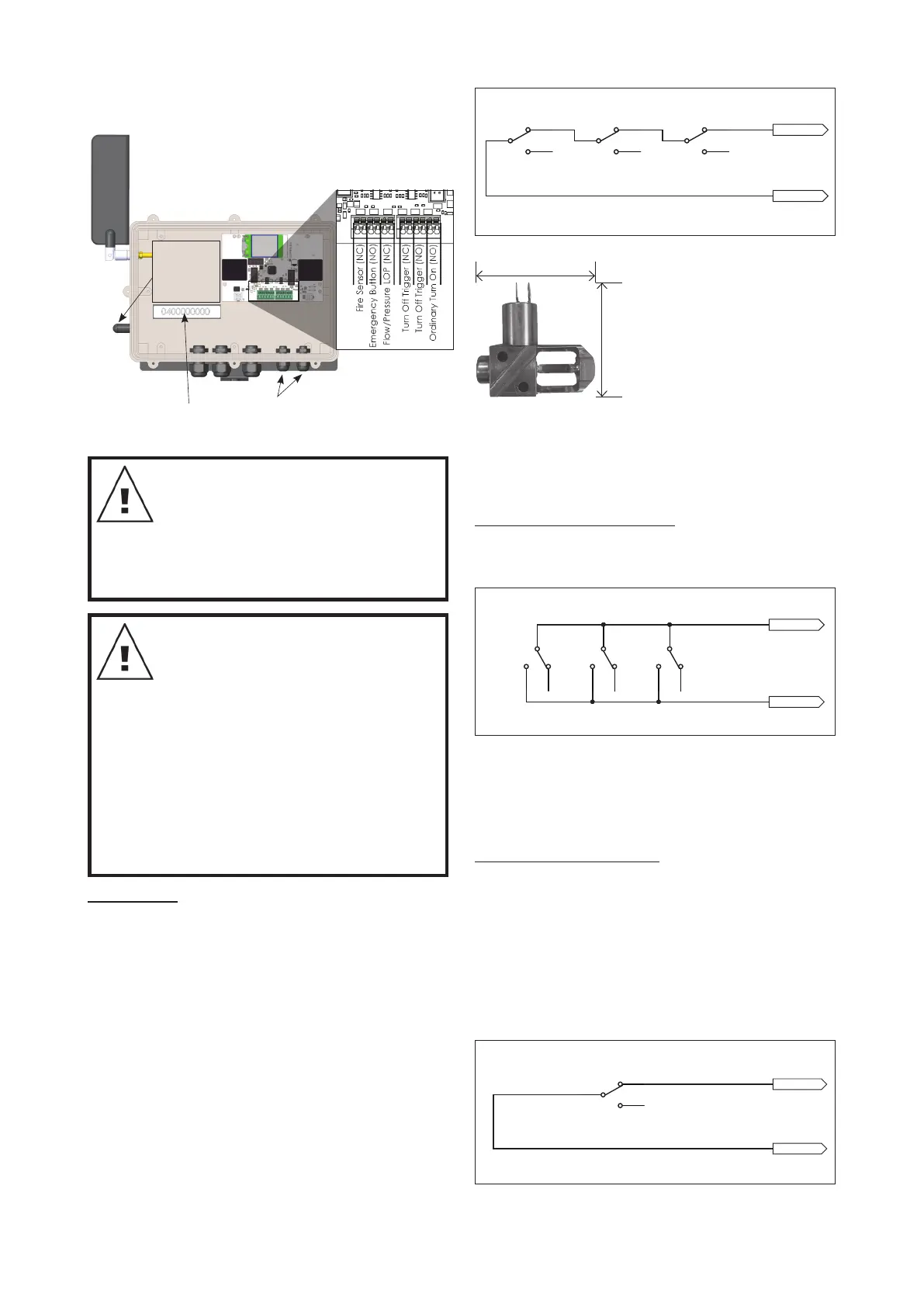

60mm

60mm

Figure 7.5

Once the pump is started via Fire Sensor it can only

be stopped via manual stopping (Turn the key to

“off”) or an SMS command to “stop” or the pump has

run out of fuel / oil alert shut down.

Emergency Switch or Button: These are used for

localised remote starting via a normally open push

button or switch. This is not an “on/off” switch, only

an “on” switch.

2

3

1

2

3

1

2

3

1

Normally closed, stay on when open - only SMS can turn off

Fire Sensors

Input 1

GND 1

2

3

1

Normally open, stay on when closed - only SMS can turn off.

Emergency Button(s)

Input 2

GND 2

2

3

1

2

3

1

Normally open, turn on when closed,

off when open or Pressure or Float or LOP.

Ordinary Turn On Switch

Input 6

GND 6

2

3

1

2

3

1

At turn on, check closed within 4 minutes - otherwise LOP fault

Flow/Pressure LOP Switch

Input 3

GND 3

Once running, if opens fault after 30 seconds Bridge if not used.

Normally open, turn off when closed.

Float Turn-off

Input 5

GND 5

2

3

1

2

3

1

Normally closed, turn off when opened Bridge if not used.

Pressure Switch Turn-off (Tank or Shut-head)

Input 4

GND 4

Bridge if not used.

Normally open, run low speed when closed.

Speed Input

Input 7

GND 7

2

3

1

Figure 7.6

Once the pump is started via Emergency Switch or

Button it can only be stopped via manual stopping

(Turn the key to “off”) or and SMS command to “stop”

or the pump has run out of fuel / oil alert shut down.

Flow/Pressure LOP Switch: This function allows for

a ow or pressure switch to be connected to detect

correct operation and shut down in the event of

closed head (ow switch option only) or loss of prime

(no ow or no pressure dependant on sensor used).

This option works best with a basic ow switch,

as the initiation time delay of 4 minutes is built in

allowing for a pump to gain prime (manual or SMS).

Once the pump is running LOP is also tied to a shut

down in the event of no ow after 30 seconds.

2

3

1

2

3

1

2

3

1

Normally closed, stay on when open - only SMS can turn off

Fire Sensors

Input 1

GND 1

2

3

1

Normally open, stay on when closed - only SMS can turn off.

Emergency Button(s)

Input 2

GND 2

2

3

1

2

3

1

Normally open, turn on when closed,

off when open or Pressure or Float or LOP.

Ordinary Turn On Switch

Input 6

GND 6

2

3

1

2

3

1

At turn on, check closed within 4 minutes - otherwise LOP fault

Flow/Pressure LOP Switch

Input 3

GND 3

Once running, if opens fault after 30 seconds Bridge if not used.

Normally open, turn off when closed.

Float Turn-off

Input 5

GND 5

2

3

1

2

3

1

Normally closed, turn off when opened Bridge if not used.

Pressure Switch Turn-off (Tank or Shut-head)

Input 4

GND 4

Bridge if not used.

Normally open, run low speed when closed.

Speed Input

Input 7

GND 7

2

3

1

Figure 7.7

Loading...

Loading...