8

4.2 Pipe Installation

It is recommended to install isolation valves on both sides of the pump, so that the

system will not be drained during pump maintenance. If the pump is installed

above the water level, a foot valve must be installed on the suction pipe under the

liquid level. The correct pipe size should be selected according to the inlet pressure

of the pump.

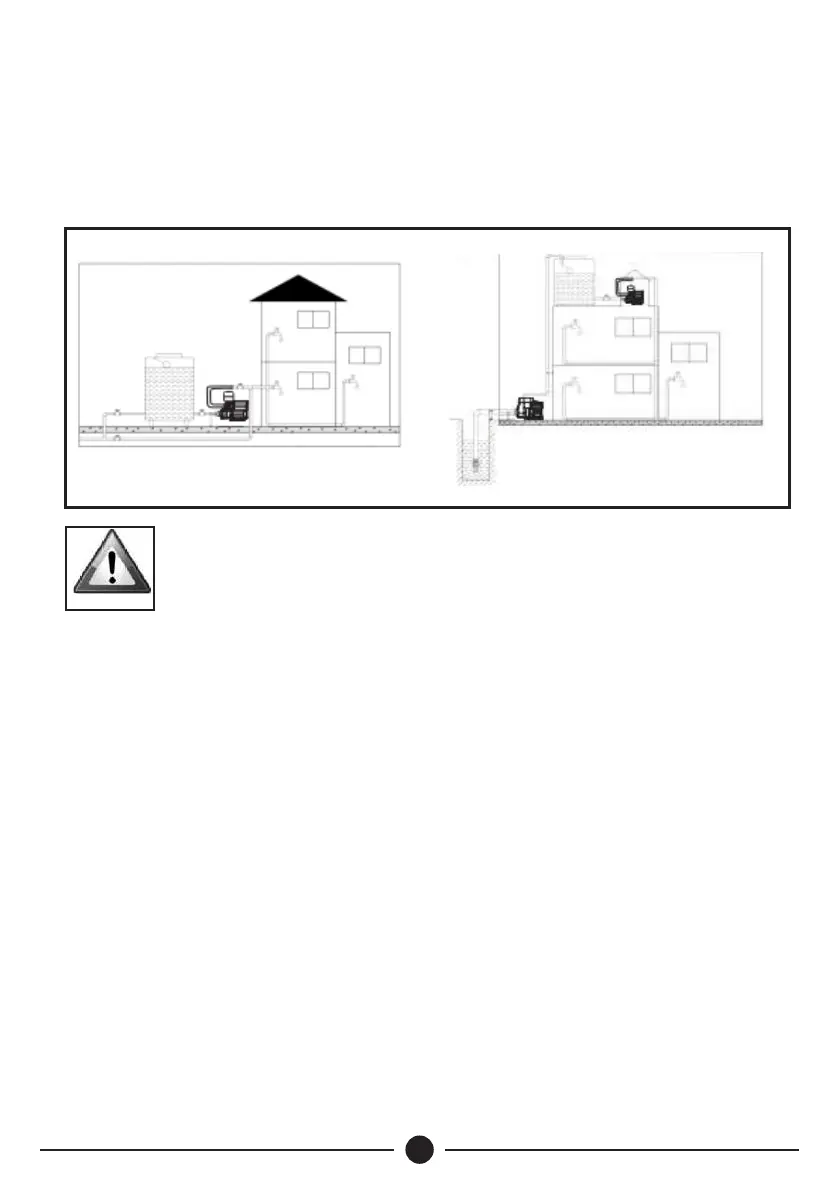

Indirectly-pressurized supply of tap water

Water supply to water tank on

roof and downward pressurization

of water supply

4.3 Pump Installation

! Pump should be installed in well ventilated cool place and away from direct

sunlight for effective air flow around the cooling fan of the motor, ensure the

pump is atleast 150mm away from obstacles.

! In order to minimize the inlet friction loss, the inlet pipe should be as short as

possible.

! Before pump installation check that pipe system has check valve fixed to

prevent water backflow.

! Pump should be installed on a rigid and level ground.

! Before pump installation, inlet pipes should be clean, and if need be a screen

filter may be installed infront of the inlet 0.5 ~ 1 m.

! When installing the inlet pipe, ensure that air is not trapped inside.

! When pump is installed above water level (within allowable suction head), the

suction pipe should be fitted with a foot valve to maintain prime.

WARNING

Do not put the weight of the piping on the pump, else

deformation will occur. When installing the inlet pipe,

prevent air from being drawn in.

Loading...

Loading...