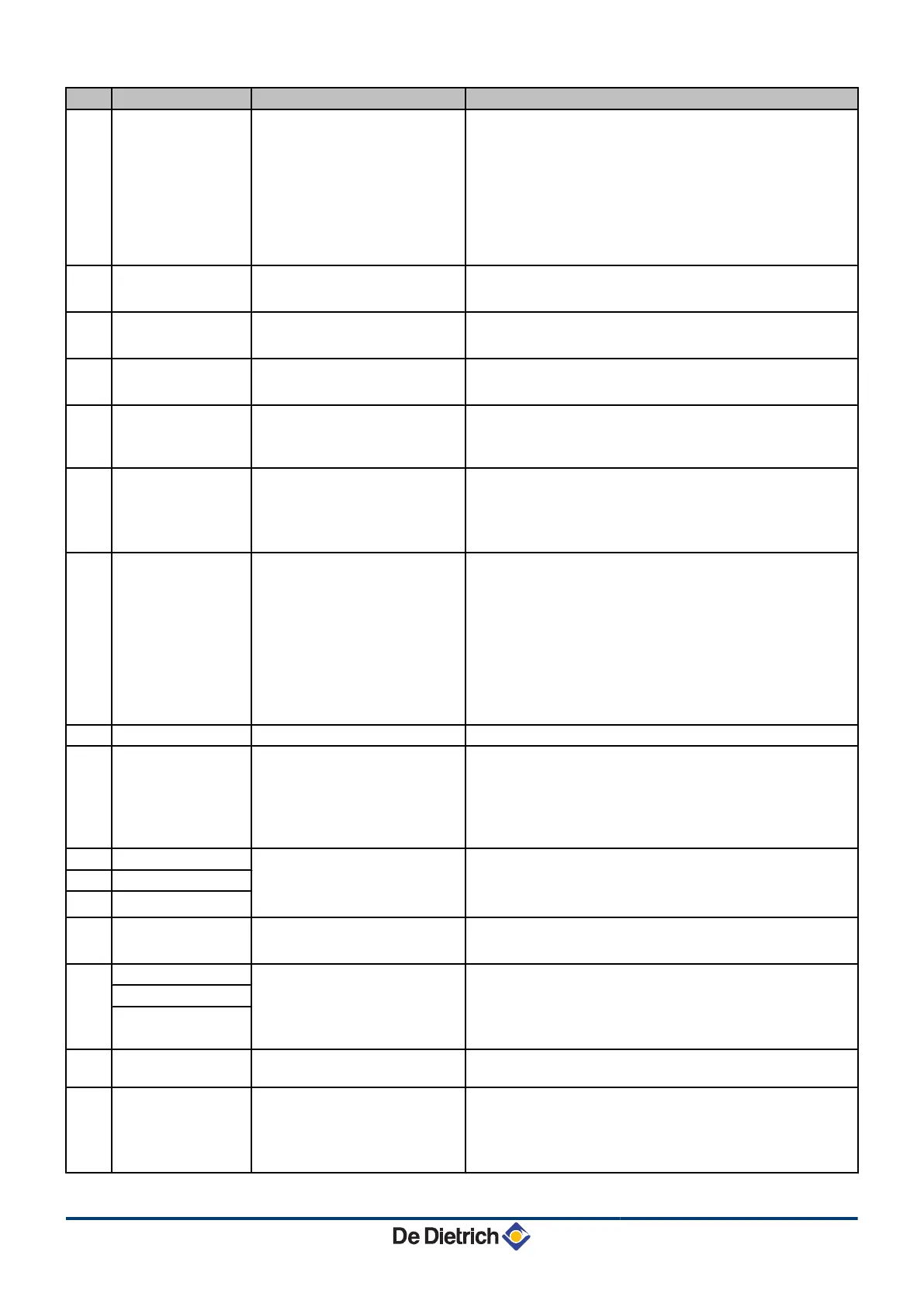

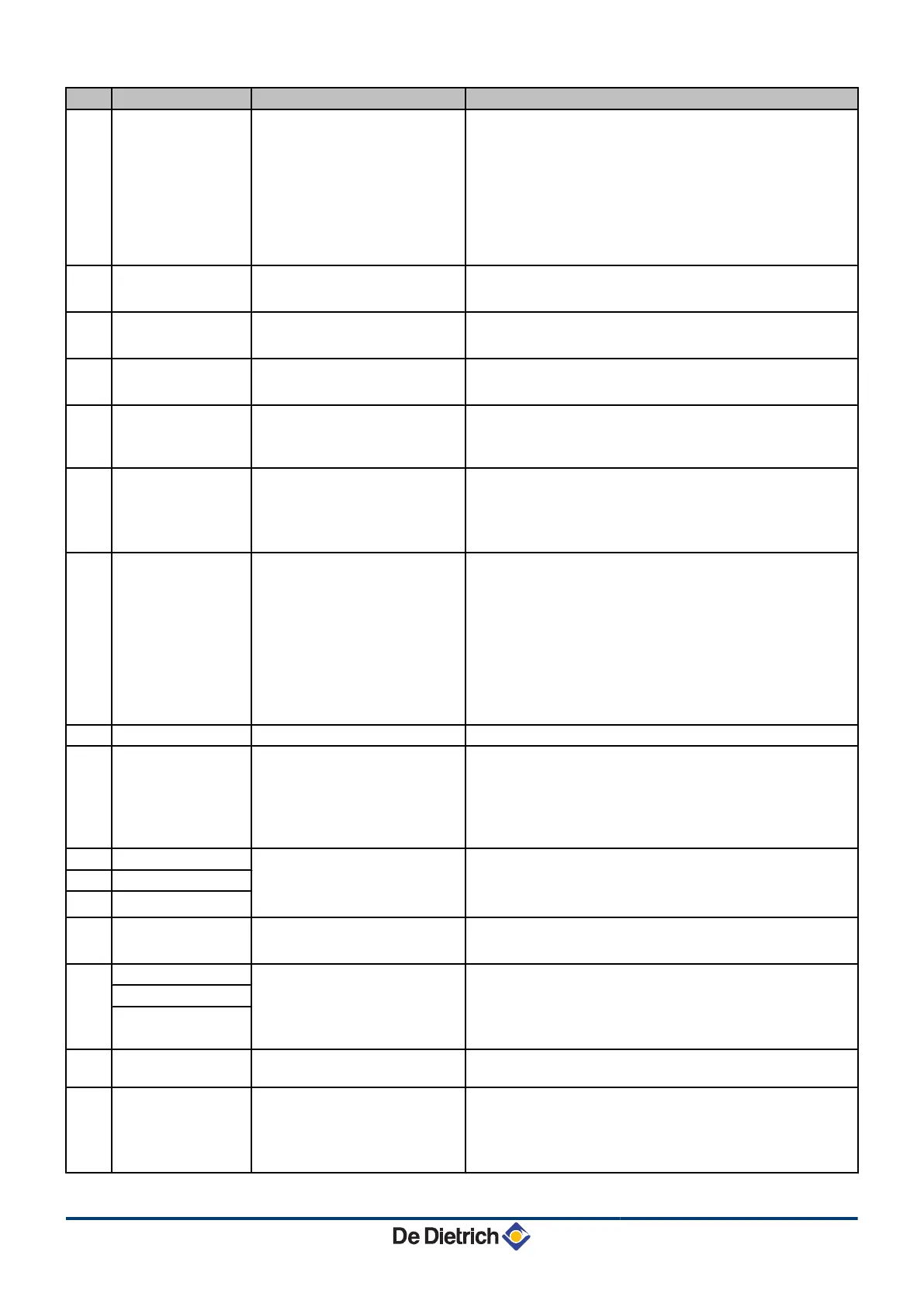

Code Messages Description Checking / solution

B15 BL.GAS PRESS

4 Incorrect setting of the gas

pressure switch on the SCU

PCB

4 Gas pressure too low

4 Wiring fault

4 Pressure switch is not or

badly fitted

4 Gas valve defect

Incorrect setting of the gas pressure switch on the SCU PCB

4 Check that the gas valve is fully opened

4 Checking the gas supply pressure

4 Check whether the gas pressure control system has been

correctly fitted

4 Replace the gas pressure control system if need be

4 Check the gas valve and replace if necessary

B16 BL.BAD SU

The SU PCB is not recognised Wrong SU PCB for this boiler

4 Replace the SU PCB

B17 BL.BAD PSU

The parameters saved on the

PCU PCB are impaired

Parameter error on the PCU PCB

4 Replace the PCU PCB

B18 BL.BAD PSU

The PSU PCB is not recognised Wrong PSU PCB for this boiler

4 Replace the PSU PCB

B19 BL.NO CONFIG

The boiler has not been

configured

The PSU PCB has been changed

4 Set the type of generator again in the menu

#CONFIGURATION (Refer to the original rating plate)

B21 BL.COM SU

Communication error between

the PCU and SU PCBs

Bad connection

4 Check that the SU PCB has been correctly put in place on

the PCU PCB

4 Replace the SU PCB

B22 BL.FLAME LOS

No flame during operation No ionization current

4 Purge the gas supply to remove air

4 Check that the gas valve is fully opened

4 Check the supply pressure

4 Check the operation and setting of the gas valve unit

4 Check that the air inlet and flue gas discharge flues are not

blocked

4 Check that there is no recirculation of flue gases

B25 BL.SU ERROR

Internal error on the SU PCB

4 Replace the SU PCB

M04 REVISION

A service is required The date programmed for the service has been reached

4 Carry out maintenance on the boiler

4 To clear the inspection, programme another date in the

menu #REVISION or set the parameter REVISION TYPE

to OFF

M05

REVISION A

An A, B or C service is required The date programmed for the service has been reached

4 Carry out maintenance on the boiler

4 To clear the inspection, press key t

M06 REVISION B

M07 REVISION C

M20 DISGAS

A boiler vent cycle is underway Switching the boiler on

4 Wait 3 minutes

FL.DRY.B XX DAYS

Floor drying is active

XX DAYS = Number of days’ floor

drying remaining.

Floor drying is underway. Heating on the circuits not concerned

is shut down.

4 Wait for the number of days shown to change to 0

4 Set the parameter SCREED DRYING to OFF

FL.DRY.C XX DAYS

FL.DRY.B+C XX

DAYS

M23 CHANGE OUTSI.S

The outside temperature sensor

is defective.

Change the outside radio temperature sensor.

STOP N XX

The shutdown is active

XX = Number of the active

shutdown

A shutdown is underway. The circuits selected for this stop are

in Antifreeze mode during the period chosen.

4 Wait until the end date has been passed

4 Set the parameter STOP NXX to OFF

7. Troubleshooting Diematic iSystem For C 330 / C 630 ECO

69

31082018 - 7600691-001-06

Loading...

Loading...