3

Signage

Because of the explosive gas mixtures generated while

charging batteries, anything that could ignite the gas, such

as sparks, open flames, an electrical arc, smoking, etc., must

be prohibited in the charging areas. To serve as a prominent

reminder, “NO SMOKING” signs should be posted in all battery

room areas.

Eye Wash Facilities

Emergency eye wash and acid neutralization facilities should

be located in the immediate work area for easy access. The

three most popular types of eye wash and acid neutralizing

equipment are the chemical burn station, deluge shower, and

eye wash fountain.

Consult all applicable Local, State, and Federal codes to ensure

compliance.

BATTERY OPERATION

There are several factors that affect the operation of the battery

concerning its ability to deliver capacity and life expectancy.

Storage

IEEE recommends:

Batteries should be stored indoors in a clean, cool, dry, level,

well-ventilated area away from direct sunlight. Typical storage tem-

perature range is 32°F (0°C) to 86°F (30°C).

Storage time should be limited to 3 – 6 months. It is recom-

mended the battery be fully charged and the electrolyte is at the

proper level, prior to storing. If the battery must be stored for sev-

eral months, a freshening charge should be given whenever the

voltage falls below 12.40V (12V)/6.20V (6V). If the average storage

temperature is below 77°F (25°C), check the voltage at least once

every two months. If the temperature is above 77°F (25°C), check

it every month.

Batteries should be covered with a non-conductive

material to protect them from dirt, moisture, etc. A flat sheet of

rigid plastic or plywood is not recommended. Do not drape flexi-

ble plastic sheeting over batteries because it may trap explosive

gases underneath.

Note: If batteries are to be stored for more than 6 months,

consult with nearest authorized East Penn representative.

Temperature

Many chemical reactions are effected by temperature, and this is

true of the reaction that occurs in a storage battery.

The chemical reaction of a lead-acid battery is slowed down by a

lowering of the electrolyte temperature that results in less capacity.

A battery that will deliver 100% of rated capacity at 77° F will only

deliver 65% of rated capacity at 32°F.

Excessive heat will increase the natural corrosion factors of a

lead acid battery. This increase corrosion of the positive plates

contributes greatly to reducing the overall life of the battery.

Depth of Discharge (DoD)

Depth of discharge is a function of design. The deeper the dis-

charge per cycle the shorter the life of the battery. A cycle is a

discharge and its subsequent recharge regardless of depth of

discharge.

System should be designed for shallow discharges. The result

of shallower discharges is typically a larger capacity battery at

prolonged battery life.

Charging

Majority of battery issues can be traced to improper charging.

Improper charging settings will lead to overcharging or under-

charging condition. Each condition will result in reduced capacity

and/ or battery life.

To ensure proper charging the inverter / charge controller

should be set to the recommended battery voltage settings. If

battery is located in an uncontrolled temperature environment,

temperature compensation should be used.

Maintenance

IEEE 450 suggests batteries be checked on a monthly,

quarterly and yearly basis. Each time period requires different

checks. Maintenance log should be initiated at time of installa-

tion. Typical checks consists of voltage & specific gravity read-

ings and well as visual inspections. Periodic verification of proper

gravity readings and electrolyte levels will ensure battery being

fully charged and operating properly. If any conditions are found

that are out of specifications, corrections should be made.

A good battery maintenance program is necessary to protect

life expectancy and capacity of the battery.

BATTERY INSTALLATION

Receiving a Battery

After receiving a battery, examine the crate and pallet for

signs of damage. If you see any wet spots, the battery may have

been tipped or damaged during transit. Be careful when handling

a crate or packing material that’s contaminated with spilled

electrolyte. Chemical burns can result if skin or clothing comes in

contact with the spillage.

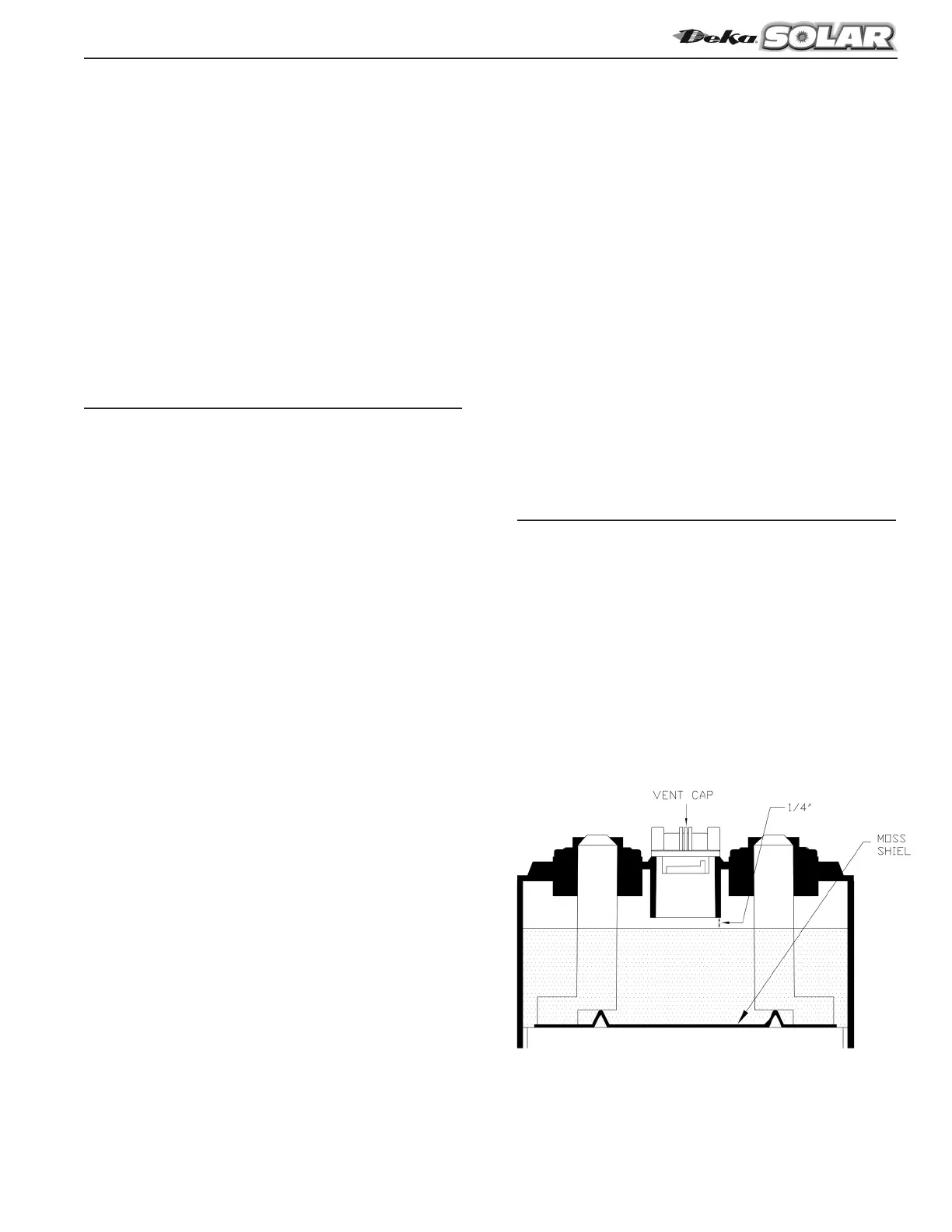

Every cell should be inspected to be sure that the electrolyte

level is above the moss shield. If the electrolyte level is slightly

below the moss shield in any cell, it can be raised by transferring

a small amount of acid from higher level cells within the battery

by using a syringe or hydrometer. Do not fill with water to bring

levels to above the moss shield.

If a large amount of liquid is required to raise the level, the

battery may be damaged. Inspect the packing material under

the tray for signs of leakage. All damaged components should be

inspected by your East Penn agent or representative.

Loading...

Loading...