12

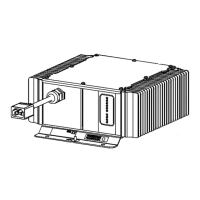

5.3 Mounting Points

Robust mounting lugs are cast into the IC650 Charger’s die cast aluminum enclosure. In each corner are

6.3mm (1/4”) diameter slots, arranged to allow ample tolerance when mating with standos or predrilled

holes in a machine. In addition, a keyhole slot has been provided to in the back of the charger so it can be

hung vertically on a wall or secured to a shelf.

If mounting the charger on a vehicle frame that may be prone to exing, it is recommended to mount the

charger using only three of the mounting points to prevent the charger case and internal components from

being subjected to undue stress and torsional loads.

Mount the charger securely using the mounting points shown in Figure 11.

In some cases, a bracket may need to be fabricated, particularly if there is insucient cooling air

ow.

Do not drill holes in the unit for mounting.

5.4 Cable Dressing

It is recommended that AC, DC and signal cables be secured, especially in applications where there are

high vibration and shock loads. To facilitate doing so, mounting points have been cast-in to each side of the

charger enclosure to provide places to attach cable ties.

Figure 11. Charger Mounting Points

Loading...

Loading...