- 7 -

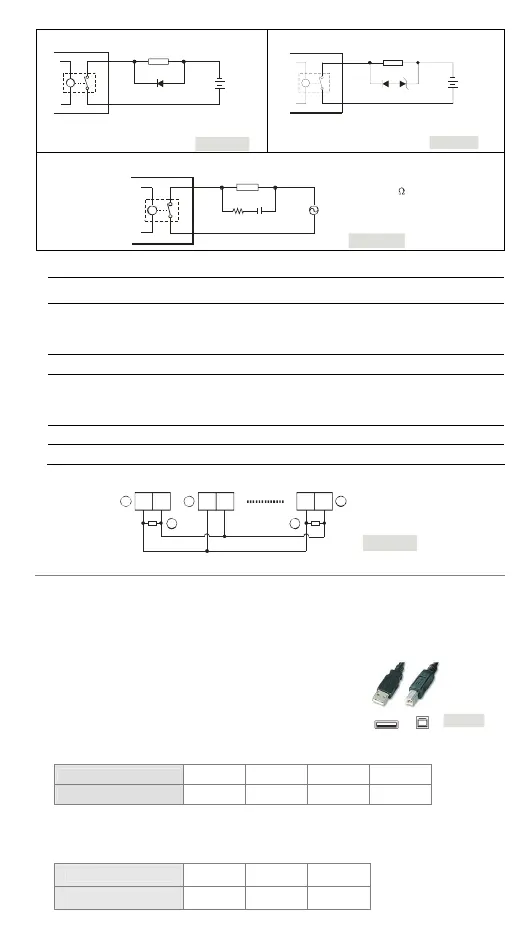

VDC

+

PLC Rela

output

Smaller power

D: 1N4001 diode or equi valent com ponent

D

F i gur e11

R

Y

C0

ZDD

VDC

+

La rger power and

frequent on/of f

ZD: 9V Z ener, 5W

F igur e 12

PLC Rela

output

D: 1N4001 diode or equi valent com ponen t

R

Y

C0

R

C

PLC Rela

output

AC loa d

R: 100~ 120

C: 0.1~0.24uF

Figure 13

R

C1

Y

○

1

DC power supply

○

2

Emergency stop: An external switch is

used.

○

3

Fuse: To protect the output circuit, a fuse having a breaking capacity within the range

between 5 A and 10 A is connected to the common terminal.

○

4

Transient voltage suppressor: It increases the life span of the terminal.

1. Diode suppression of the DC load: It will be used if the power is small. (See figure 11.)

2. Diode + Zener suppression of the DC load: It is used when the power is large, and

TP04P is turned on and off frequently. (See figure 12.)

○

5

Incandescent light (resistive load)

○

6

AC power supply

○

7

Mutually exclusive output: Y4 controls the clockwise rotation of the motor, and Y5

controls the counterclockwise rotation of the motor. The interlock circuit which is formed,

and the program in the PLC ensure that there are protective measures if an abnormal

condition occurs.

○

8

Incandescent bulb: Neon light

○

9

Absorber: It reduces the interference from the AC load. (See figure 13)

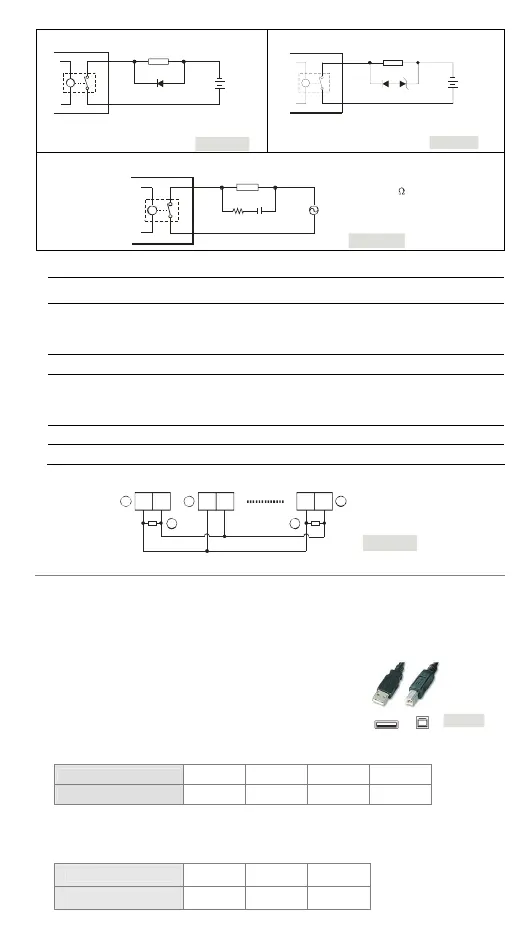

RS-485 Wiring

Figure 14

D+ D- D+ D- D+ D-

3

1 2 2

3

c

Master station

d

Slave station

e

Terminal resistor

Note: 1. The terminal resistor should be connected to the master station and the last slave

station. The resistance of the terminal resistor should be 120Ω.

2. To ensure communication quality, it is suggested that users should use double shielded

twisted pair cables (20AWG) for wiring.

Communication Connection

TP04P may connect to a PC by using USB adaptor cable.

Please use an AM/BM USB adaptor cable.

Figure15

Battery’s Life

Temperature (°C) -20 0 20 60

Life (Year) 2.0 2.5 2.7 2.8

Precision of the Real Time Clock

(Second/Month)

Temperature (°C/°F) 0/32 25/77 55/131

Maximum error (Second) -117 52 -132

Loading...

Loading...