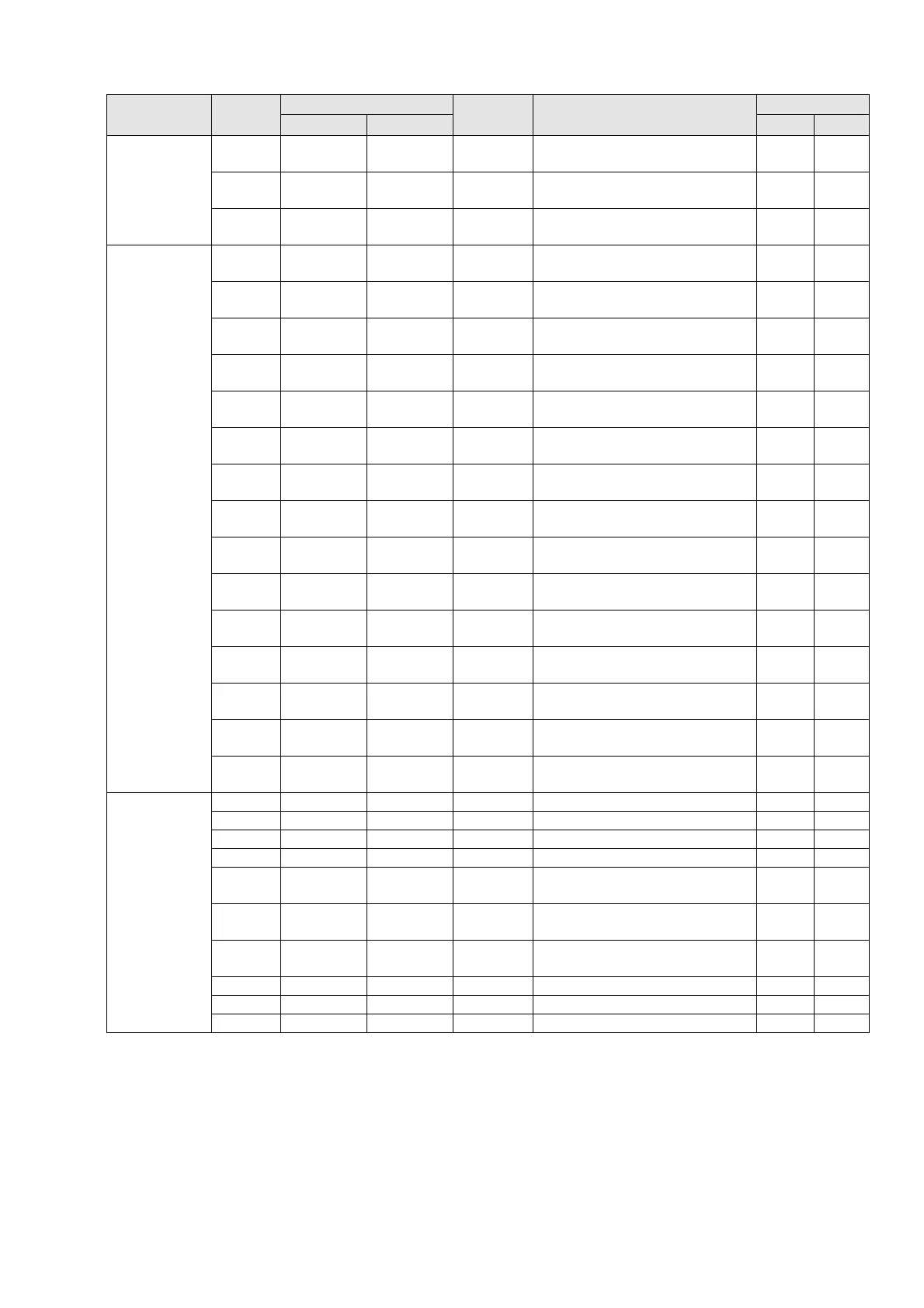

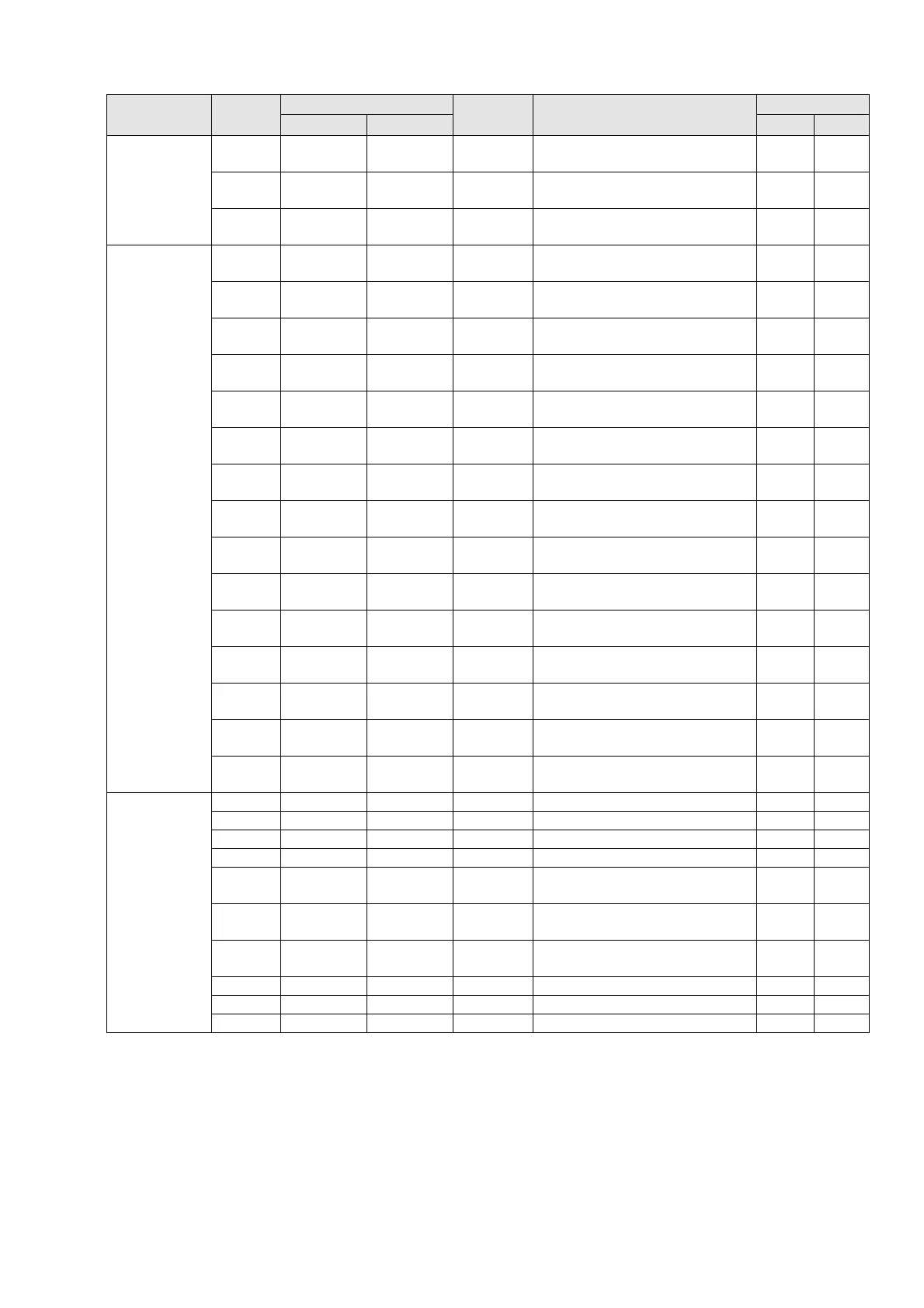

Chapter 16 PLC Function Applications│CP2000

16-55

Classification API

Command code

P

command

Function

STEPS

16 bit 32 bit 16bit 32bit

Floating point

contact form

275 –

FLD=

–

Floating point number contact

form compare LD

※

– 9

276 –

FLD>

–

Floating point number contact

form compare LD

※

– 9

277 –

FLD<

–

Floating point number contact

form compare LD

※

– 9

Compare

command

278 –

FLD<>

–

Floating point number contact

form compare LD

※

– 9

279 –

FLD<=

–

Floating point number contact

form compare LD

※

– 9

280 –

FLD>=

–

Floating point number contact

form compare LD

※

– 9

281 –

FAND=

–

Floating point number contact

form compare AND

※

– 9

282 –

FAND>

–

Floating point number contact

form compare AND

※

– 9

283 –

FAND<

–

Floating point number contact

form compare AND

※

– 9

284 –

FAND<>

–

Floating point number contact

form compare AND

※

– 9

285 –

FAND<=

–

Floating point number contact

form compare AND

※

– 9

286 –

FAND>=

–

Floating point number contact

form compare AND

※

– 9

287 –

FOR=

–

Floating point number contact

form compare OR

※

– 9

288 –

FOR>

–

Floating point number contact

form compare OR

※

– 9

289 –

FOR<

–

Floating point number contact

form compare OR

※

– 9

290 –

FOR<>

–

Floating point number contact

form compare OR

※

– 9

291 –

FOR<=

–

Floating point number contact

form compare OR

※

– 9

292 –

FOR>=

–

Floating point number contact

form compare OR

※

– 9

Driver special

command

139 RPR –

Read servo parameter 5 –

140 WPR –

Write servo parameter 5 –

141 FPID –

Driver PID control mode 9 –

142 FREQ –

Driver torque control mode 7 –

261 CANRX –

Read CANopen slave station

data

9 –

264 CANTX –

Write CANopen slave station

data

9

–

265 CANFLS –

Refresh special

D corresponding to CANopen

3

–

320 ICOMR DICOMR

Internal communications read 9 17

321 ICOMW DICOMW

Internal communications write 9 17

323 WPRA – – RAM write in drive parameters 5 –

Loading...

Loading...