Chapter 14 Fault Codes and DescriptionsME300

14-5

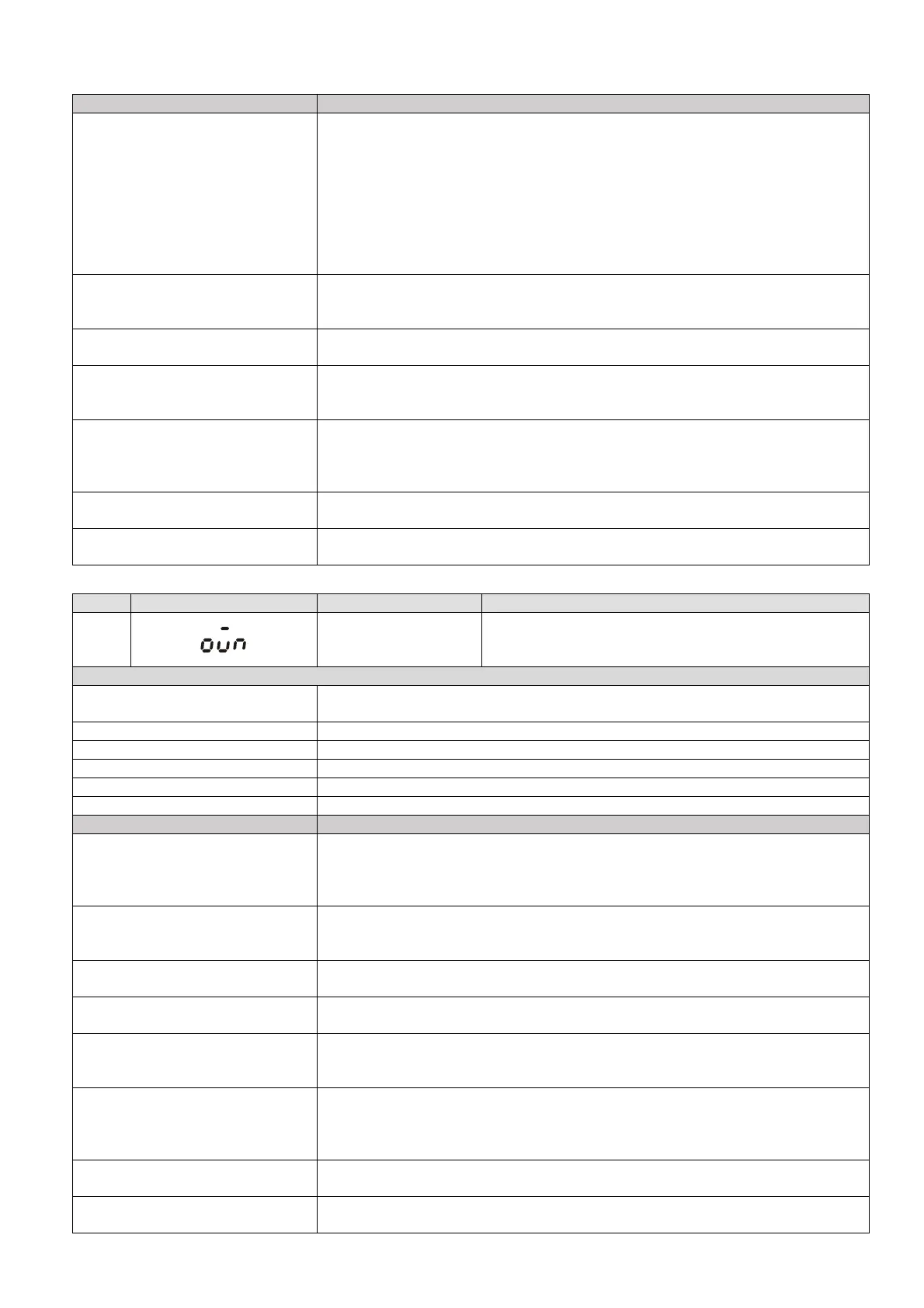

Cause Corrective Actions

Deceleration time is too short,

causing too large regenerative

energy of the load.

1. Increase the setting value for Pr.01-13, Pr.01-15, Pr.01-17 and Pr.01-19

(deceleration time).

2. Connect brake resistor, brake unit or DC BUS to the drive.

3. Reduce the brake frequency.

4. Replace the drive with a larger capacity model.

5. Use S-curve acceleration/deceleration.

6. Use over-voltage stall prevention (Pr.06-01).

7. Use auto-acceleration and auto-deceleration (Pr.01-44).

8. Adjust braking level (Pr.07-01 or the bolt position of the brake unit).

The setting for stall prevention

level is smaller than no-load

current.

The setting for stall prevention level should be larger than no-load current.

Power voltage is too high.

Check if the input voltage is within the rated AC motor drive input voltage range,

and check for possible voltage spikes.

ON/OFF switch action of phase-in

capacitor in the same power

system

If the phase-in capacitor or active power supply unit acts in the same power

system, the input voltage may surge abnormally in a short time. In this case,

install an AC reactor.

Motor ground fault

The ground short circuit current charges the capacitor in the main circuit through

the power. Check if there is ground fault on the motor cable, wiring box and its

internal terminals.

Troubleshoot the ground fault.

Incorrect wiring of brake resistor or

brake unit

Check the wiring of brake resistor or brake unit.

Malfunction caused by interference

Verify the wiring of the control circuit and wiring/grounding of the main circuit to

prevent interference.

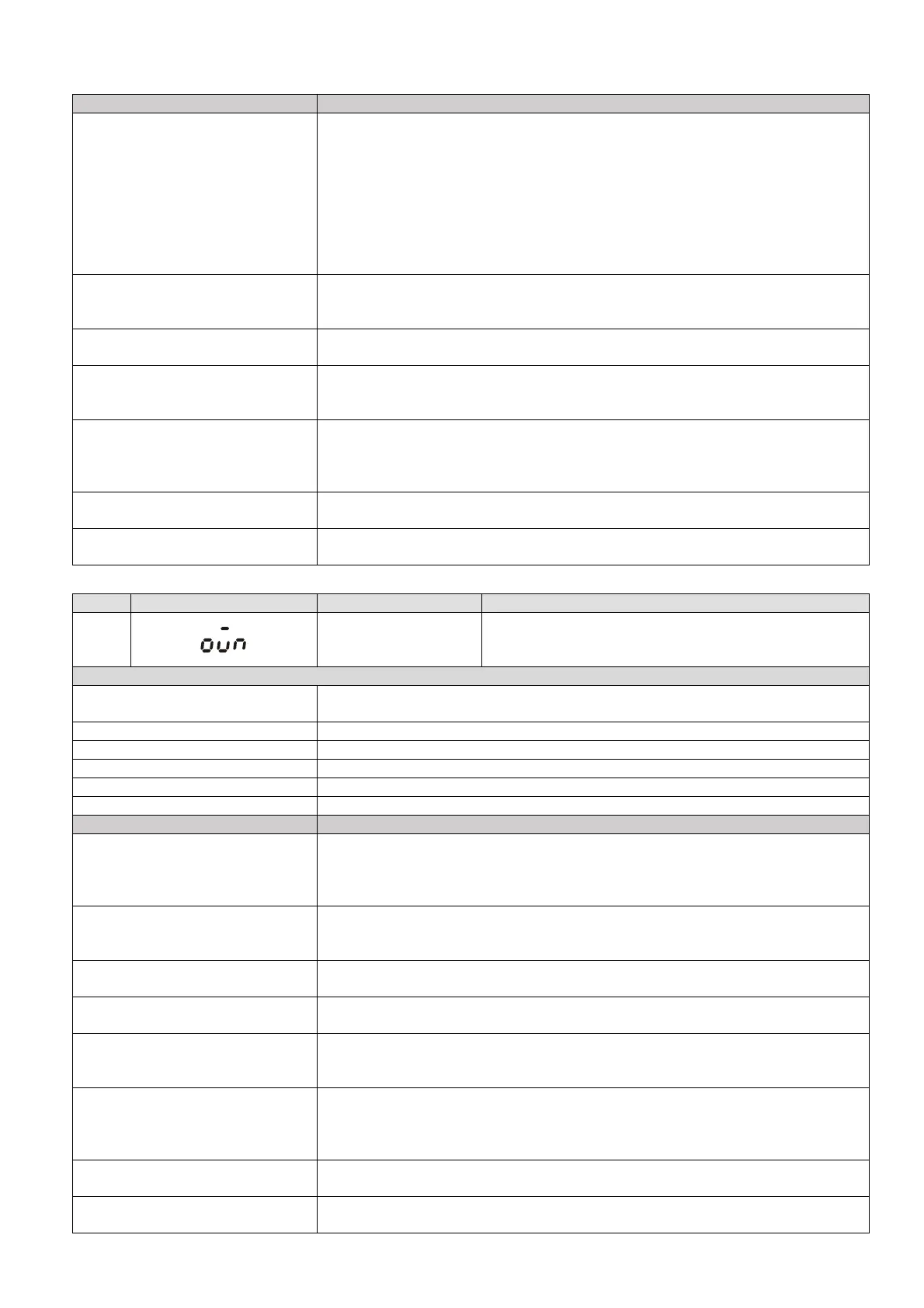

ID No. Display on LCM Keypad Fault Name Fault Descriptions

9

Over-voltage at

constant speed

(ovn)

DC BUS over-voltage at constant speed. When ovn

occurs, the drive closes the gate of the output, motor

runs freely, and the display shows an ovn error.

Action and Reset

Action level

230V series: 410 V

DC

460V series: 820 V

DC

Action time Immediately act when DC BUS voltage is higher than the level.

Fault treatment parameter N/A

Reset method Manual reset

Reset condition Reset only when DC BUS voltage is lower than 90% of the over-voltage level.

Record Yes

Cause Corrective Actions

Impulsive change of the load

1. Connect brake resistor, brake unit or DC BUS to the drive.

2. Reduce the load.

3. Replace the drive with a larger capacity model.

4. Adjust braking level (Pr.07-01 or the bolt position of the brake unit).

The setting for stall prevention

level is smaller than no-load

current.

The setting for stall prevention level should be larger than no-load current.

Regenerative voltage of motor

inertia

Use over-voltage stall prevention function (Pr.06-01)

Use a brake unit or DC BUS

Power voltage is too high.

Check if the input voltage is within the rated AC motor drive input voltage range,

and check for possible voltage spikes.

ON/OFF switch action of phase-in

capacitor in the same power

system

If the phase-in capacitor or active power supply unit acts in the same power

system, the input voltage may surge abnormally in a short time. In this case,

install an AC reactor.

Motor ground fault

The ground short circuit current charges the capacitor in the main circuit through

the power. Check if there is ground fault on the motor cable, wiring box and its

internal terminals.

Troubleshoot the ground fault.

Incorrect wiring of brake resistor or

brake unit

Check the wiring of brake resistor or brake unit.

Malfunction caused by interference

Verify the wiring of the control circuit and wiring/grounding of the main circuit to

prevent interference.

Loading...

Loading...