Chapter 15 CANopen OverviewMS300

643

15-3-3 Using the Delta Standard (Old definition, only supports speed mode)

15-3-3-1 Various mode control method (following the Delta old standard)

If you want to use the Delta old standard to control the motor drive, follow these steps:

1. Wire the hardware (refer to Section 15-2 Wiring for CANopen).

2. Set the operation source: set Pr.00-21 to 3 for CANopen communication card control.

3. Set the frequency source: set Pr.00-20 to 6. Choose the source for the Frequency command

from the CANopen setting.

4. Set Delta Standard (Old definition, only supports speed mode) as the control mode: Pr.09-40

= 0 and Pr.09-30 = 0.

5. Set the CANopen station: set Pr.09-36; the range is among 1–127. When Pr.09-36 = 0, the

CANopen slave function is disabled. Note that if an error appears (station address error CAdE

or CANopen memory error CFrE) when you finish the station setting, set Pr.00-02 = 7 to reset.

6. Set the CANopen baud rate: set Pr.09-37 (CANBUS baud rate: 1 Mbps (0), 500 Kbps (1), 250

Kbps (2), 125 Kbps (3), 100 Kbps (4) and 50 Kbps (5))

15-3-3-2 The control method under speed mode

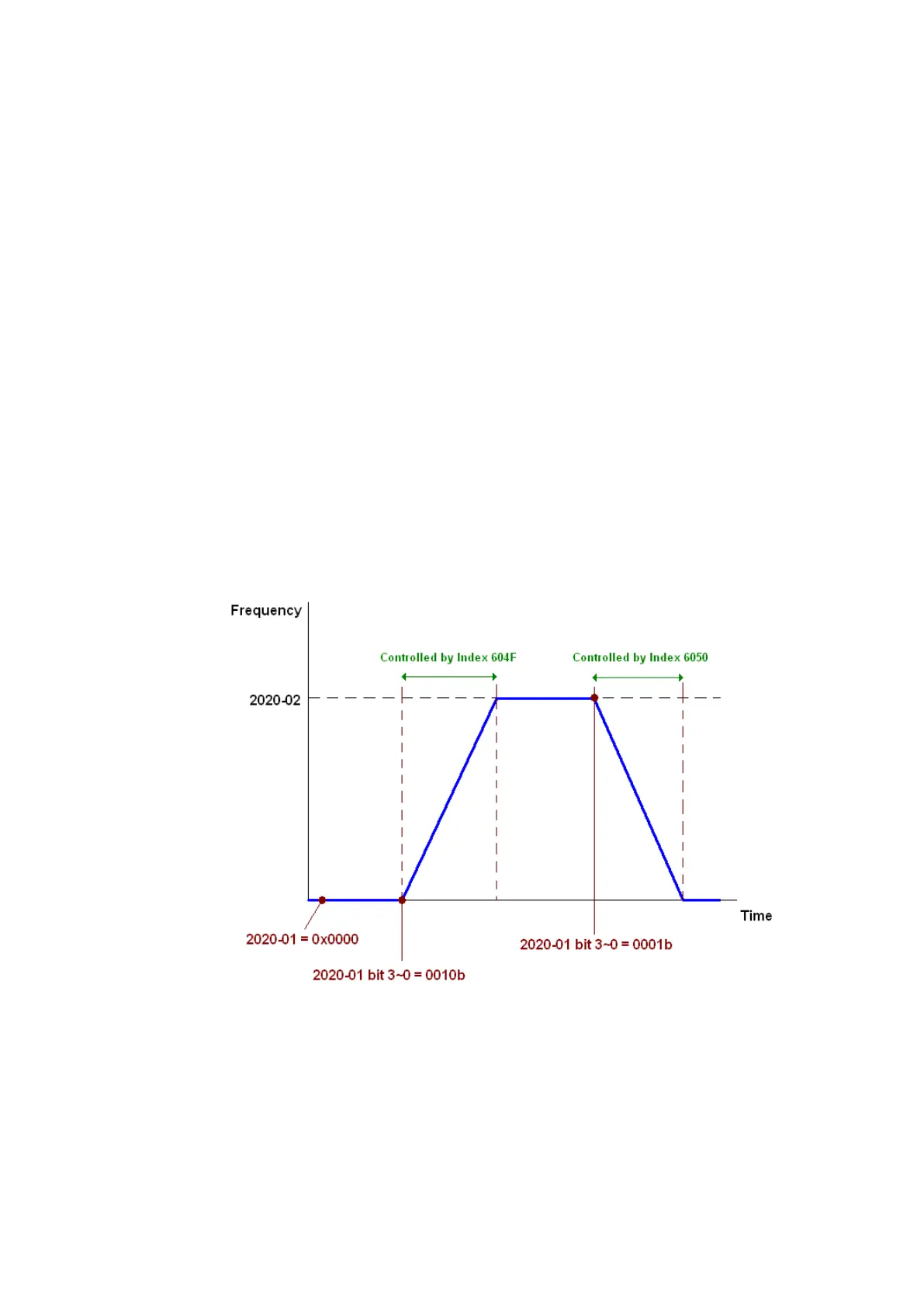

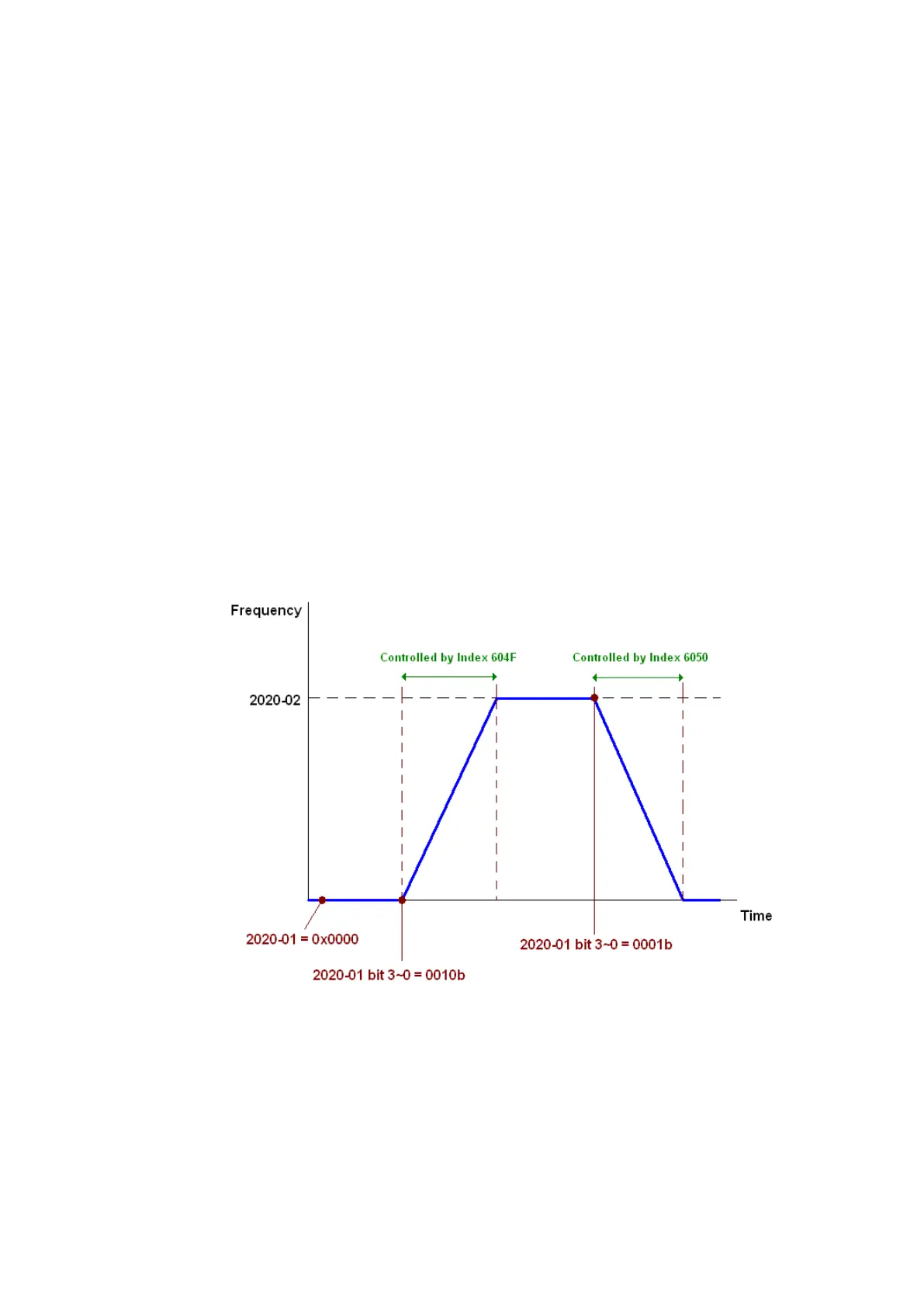

1. Set the target frequency: set 2020-02, the unit is Hz, with 2 decimal places. For example,

1000 is 10.00 Hz.

2. Operation control: set 2020-01 = 0002H for running, and set 2020-01 = 0001H for stopping.

Loading...

Loading...