Chapter 13 Warning CodesCP2000

13-11

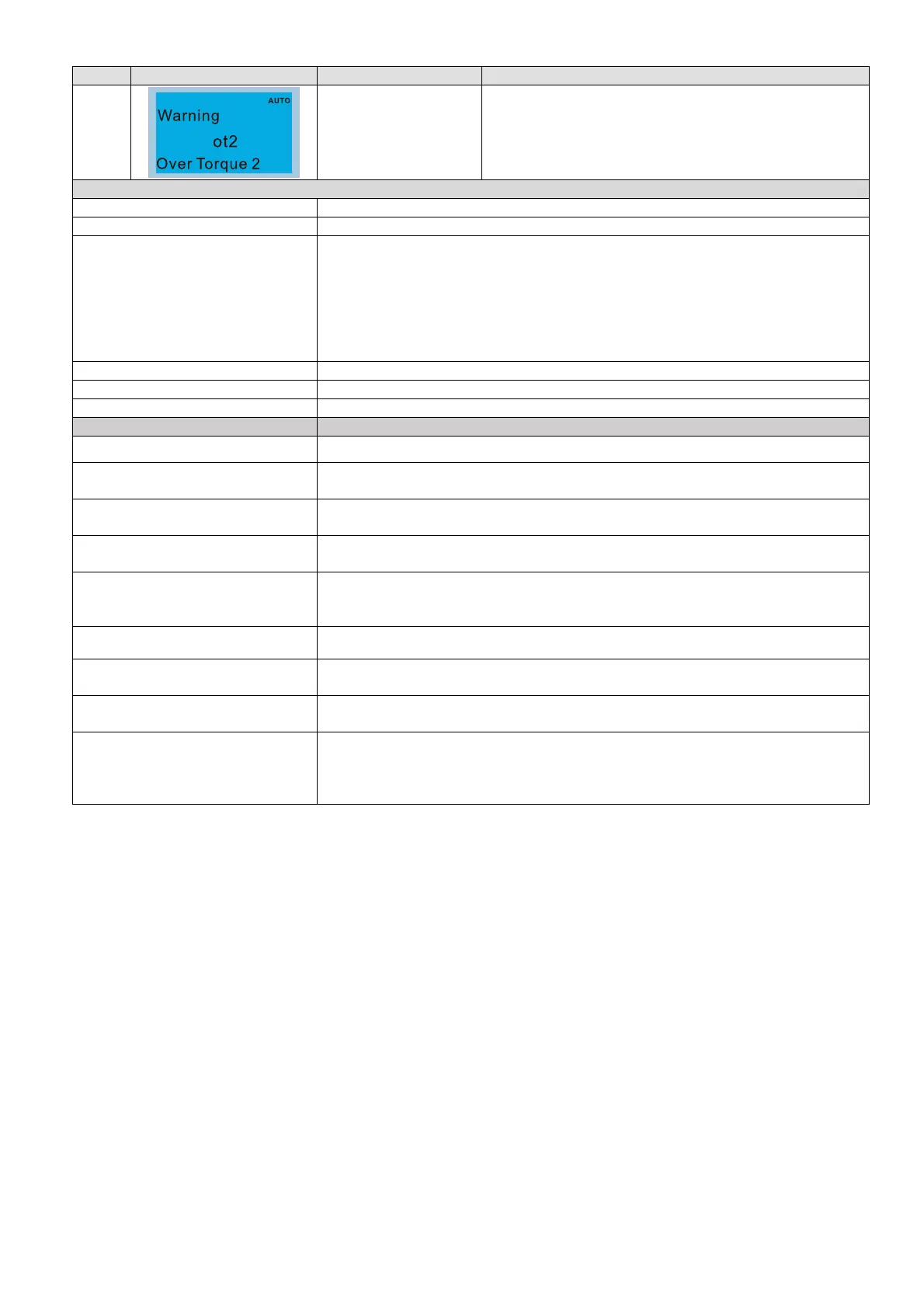

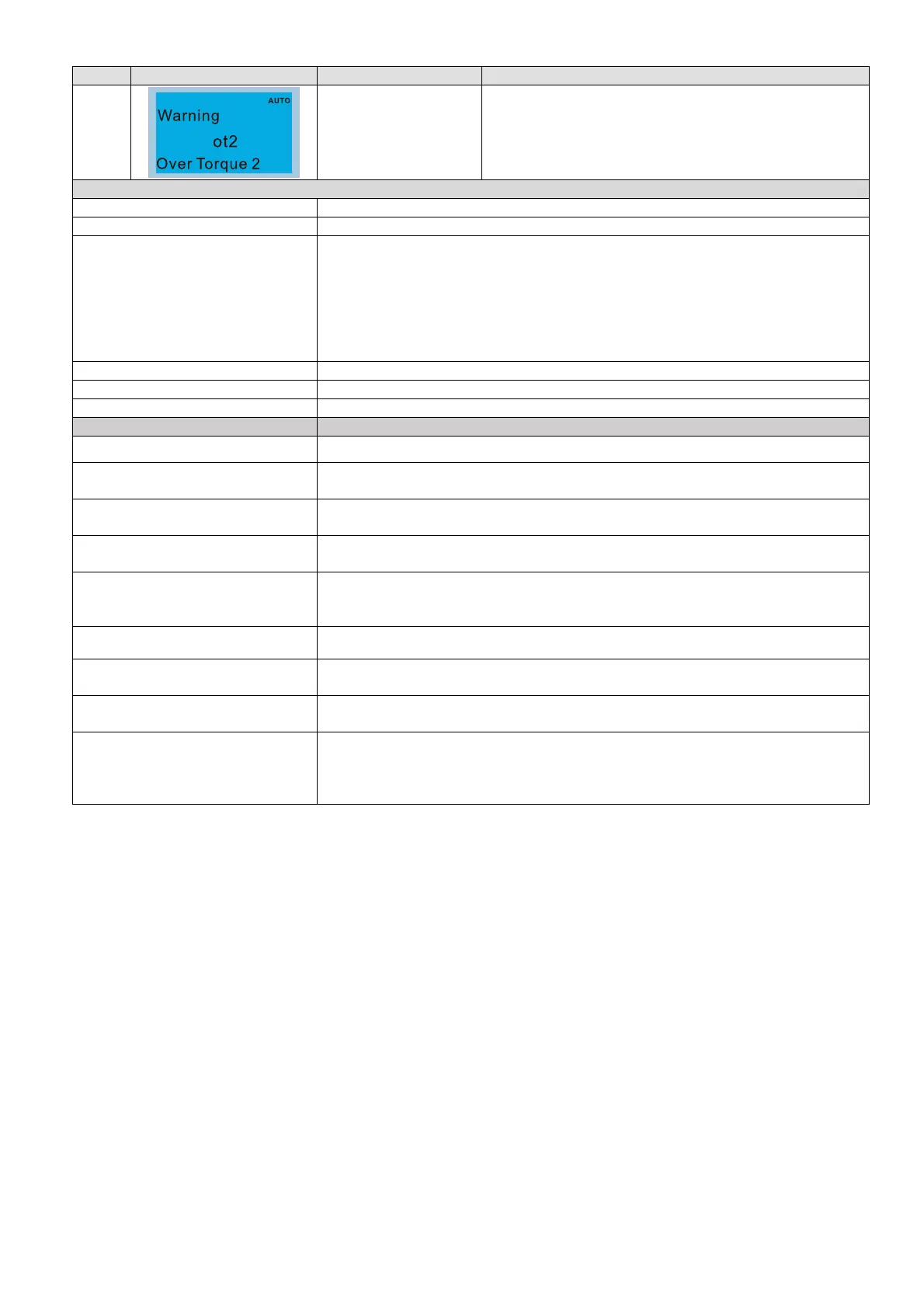

ID No. Display on LCD Keypad Warning Name Description

21

Over-torque

(ot2)

Over-torque 2 warning

Action and Reset

Action level Pr.06-10

Action time Pr.06-11

Warning setting parameter

Pr.06-09=1 or 3

0: No function

1: Continue operation after over-torque detection during constant speed

operation

2: Stop after over-torque detection during constant speed operation

3: Continue operation after over-torque detection during RUN

4: Stop after over-torque detection during RUN

Reset method When output current < (Pr.06-10 – 5%), the Ot2 warning automatically clears

Reset condition When output current < (Pr.06-10 – 5%), the Ot2 warning automatically clears

Record N/A

Cause Corrective Actions

Incorrect parameter setting Configure the settings for Pr.06-10 and Pr.06-11

Mechanical error (e.g. mechanical

lock due to over-torque)

Remove the causes of malfunction.

The load is too large

Decrease the loading.

Replace with a motor with larger capacity.

Accel./ Decel. time and working

cycle is too short

Increase the setting values for Pr.01-12–01-19 (accel./ decel. time)

V/F voltage is too high

Adjust the V/F curve (Motor 2, Pr.01-35–01-42), especially the setting value for

the mid-point voltage (if the mid-point voltage is set too small, the load capacity

decreases at low-speed).

The motor capacity is too small Replace with a motor with larger capacity.

Over-load during low-speed

operation

Decrease the loading during low-speed operation.

Increase the motor capacity.

The torque compensation is too

large

Adjust the torque compensation value (Pr.07-26 torque compensation gain) until

the output current decreases and the motor does not stall.

Improper parameter settings for

the speed tracking function

(including restart after momentary

power loss and restart after fault)

Correct the parameter settings for speed tracking.

Start speed tracking function.

Adjust the maximum current for Pr.07-09 speed tracking.

Loading...

Loading...