6

F - PROPER ADJUSTMENT OF STUFFING BOX

1. The liquid being pumped should constantly, yet slowly

drip from the stuffi ng box gland (17) when the pump

is running. This slow drip keeps the shaft from becoming

scored. NEVER tighten the gland so as to entirely stop

leakage through stuffi ng box. It increases the power and

wears the shaft in a short time.

2. The split gland (17) can be taken apart. This facilitates

repacking the stuffi ng box. Access to the packing (13) is

obtained by removing the nuts from bolts (209) which

fasten the stuffi ng box gland to the stuffi ng box head.

Clean out the drip holes in the gland occasionally as they

may become clogged, especially with new packing. The

drip hole allows the sealing liquid to drip thru the gland,

instead of passing between the gland and the shaft.

3. Standard pumps are equipped with a circulation tube

(127) from discharge to the stuffi ng box lantern ring so

that the pump will not suck air in along the shaft when

the pump is operating on a suction lift. If the pump is to

operate with positive suction head, disconnect this tube,

plug the holes concerned and run the pump with the

stuffi ng box gland as loose as possible to avoid

excessive shaft wear through the stuffi ng box.

G - GENERAL REPAIRS

If pumping any fl uid that could cause

bodily injury (Hot water, caustic, etc.),

Always use eye protection and wear

protective clothing over all exposed

body areas.

Whenever it is necessary to dismantle the pump for repairs,

it should be removed from the sub-base. Disconnect the

suction and discharge pipes and remove the four cap

screws holding pump to sub-base. Drain pump by removing

drain plug (216) in the bottom of the pump casing (1).

CLEAN AND INSPECT ALL PARTS

Extreme care should be exercised in keeping the parts

clean. Special precautions should be taken to keep ball

bearings dirt-free while in or out of the pump. The dirt will

damage the ball bearings, thus shortenting the trouble-free

service life of the pump.

Any part which is excessively worn or deteriorated should

be replaced with new parts from factory.

When ordering repairs refer to the illustrations for part

names and the pump name plate on which is stamped

the fi gure number, size and serial number. Without this

information we cannot identify the pump and parts in

question.

H - FOR INSPECTION AND REPAIR OF

LIQUID END

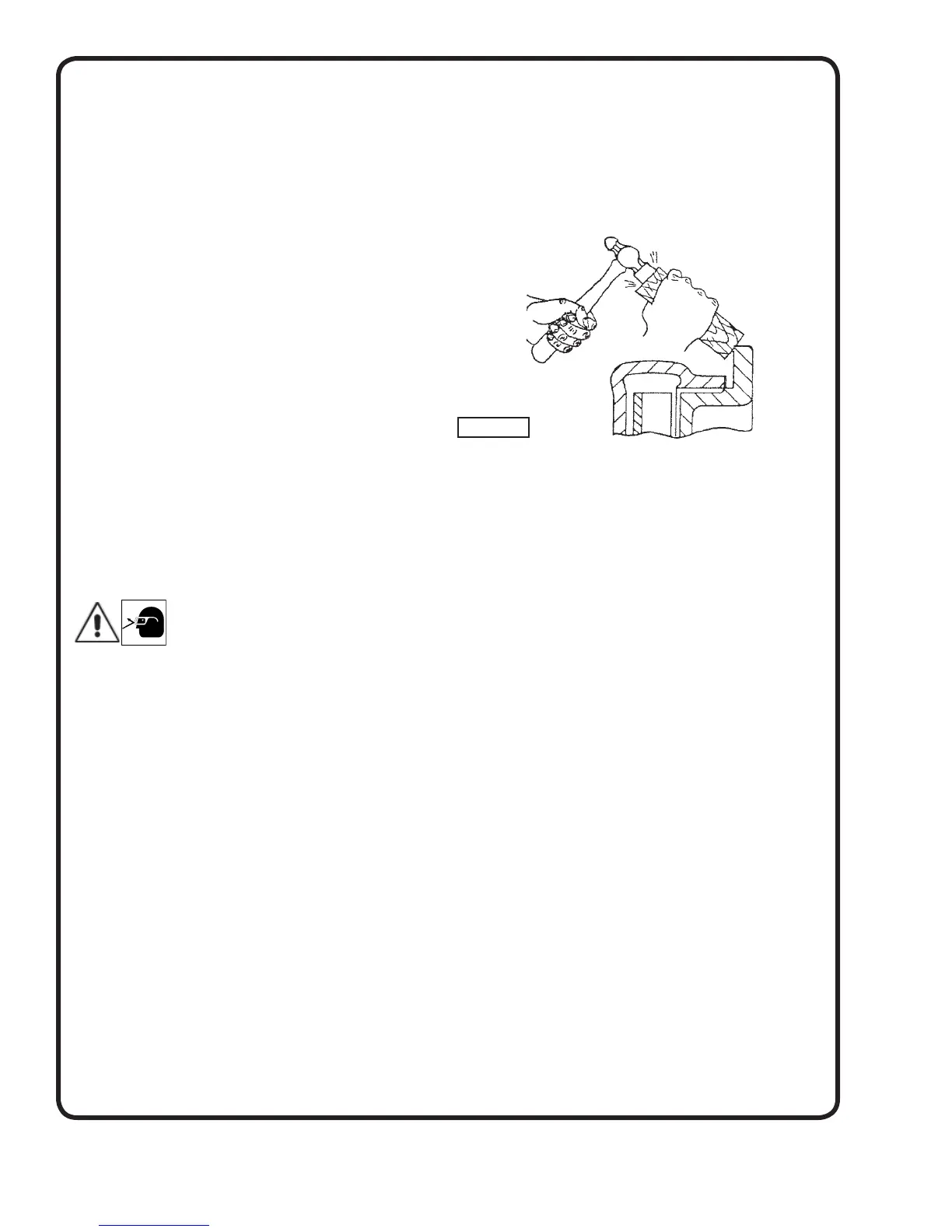

1. Remove suction head cap screws (215), then set a block

of wood against the fi nished fl ange or back of the frame

(19) and tap block lightly with a hammer to loosen

suction head. Remove suction head from pump and

place casing gasket (73) in a bucket of water to keep it

soft and pliable.

2. Bend and remove cotter pin (269) in castellated nut (24).

3. Unscrew the castellated nut (24) by turning

counter-clockwise while holding shaft (6) with a wrench

at drive coupling. Then slide impeller washer (270) off

the shaft.

4. To remove the impeller (2) from the shaft, make three

special cap screwsas follows:

Fig. 4001 - 3/8” x 16 NC with thread cut 1¾” long;

Fig. 4011 and 4021 - 1/2” x 13NC with thread cut 2” long.

Screw these cap screws into the three tapped holes in

the impeller shroud. The cap screws will tighten

against the stuffi ng box head (11) thus forcing the

impeller from the shaft. Lift key (32) from its seat in the

shaft .

5. To remove the pump casing (1), fi rst disconnect

by-pass tube (127) from the casing then remove casing

cap screws (215), casing and stuffi ng box gasket (241)

will lift off the frame (19). Place gasket in water.

6. The stuffi ng box head (11) can be removed after

loosening gland bolts (209) and nuts (210).

I - TO INSPECT OR REPLACE BALL

BEARINGS ON SHAFT

1. Dismantle liquid end of pump as described in section “H”

then loosen set screws in pump half of drive coupling

and remove coupling from pump shaft. Also remove key

(46) from shaft.

2. Unscrew bearing cover cap screws (213) remove

bearing cover (37) and gasket (303) and bearing

adjusting spring (347).Place gasket in water. Pull the

pump shaft (6) out thru the coupling end of the frame

(19). Slinger (40) will drop into support head drip basin.

Be careful not to lose it.

Figure 3

Loading...

Loading...