8

4. Apply a thin coating of clean light oil (not grease) to the

shaft and reposition seal head (52) on the support head.

Also apply a thin coating of light oil to the inside of the

seal bellows, slide the seal face carbon (D), bellows (G),

retainer (E), spring (F), spring holder (H) and spacer (61)

onto the shaft. NOTE: It may be necessary to use a

piece of tubing, slightly larger than the shaft, to push the

bellows and retainer onto the shaft. Apply pressure only

on the “tail section” of the bellows and retainer.

5. Insert casing cap screws (215) through holes in support

head and seal head and position gasket (73) on seal

head. Complete assembly of liquid end as described in

Section “K”.

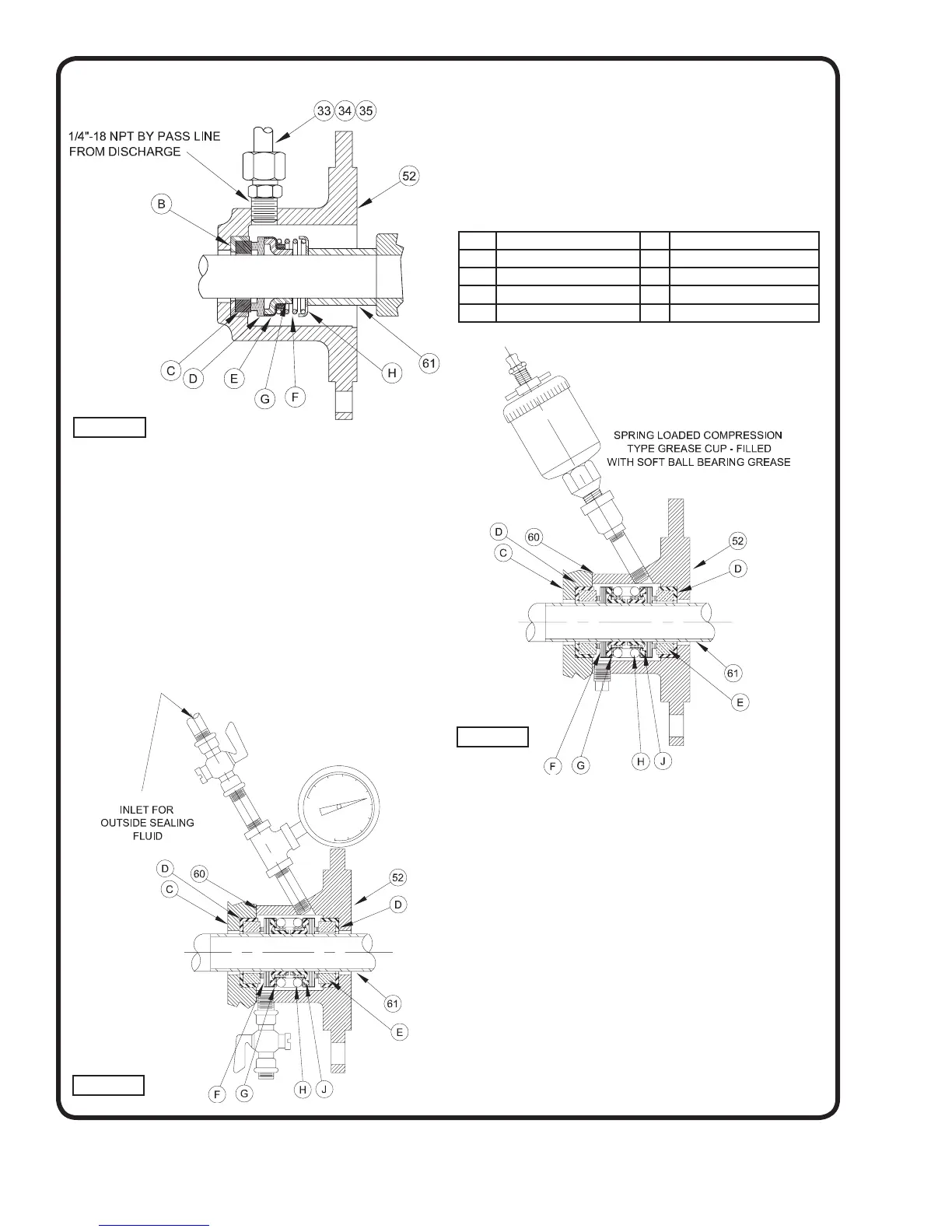

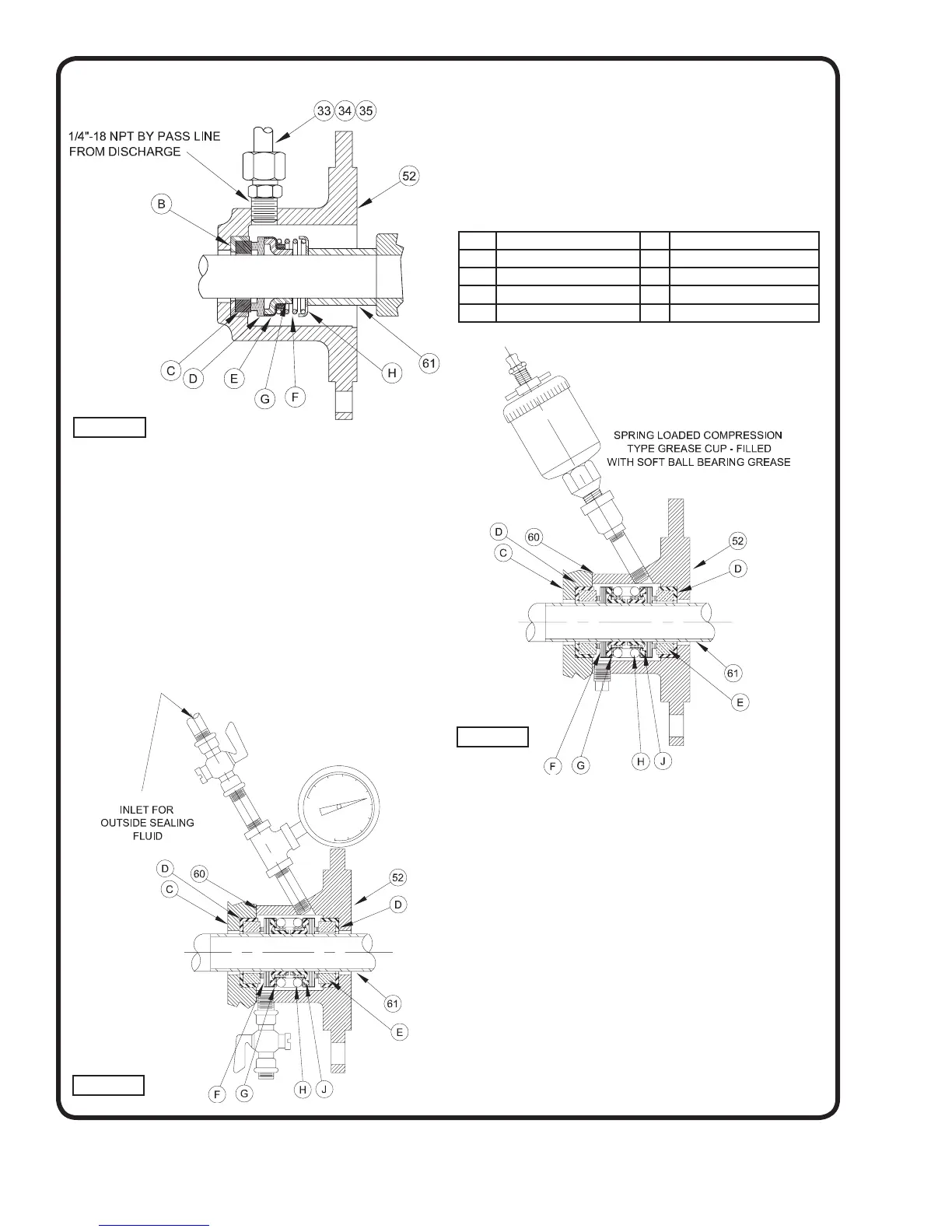

N - TO REPLACE DOUBLE MECHANICAL SEAL

Refer to Figures 5 & 6.

NOTE: Seals are available as a complete assembly only.

1. Special precautions must be observed when handling

a mechanical seal. DO NOT drop the seal face carbons

or fl oating seats nor scratch the lapped faces for these

pieces.

52 Seal Head F Seal Face Carbon

60 Seal Gasket G Retainer

C Seal Gland H Spring

D Seat Gasket J Bellows

E Floating Seat

2. To remove the seal assembly, dismantle the liquid end of

the pump as described in Section “H”, then unscrew

gland bolts (209) and nuts (210). Remove seal head

casting (52) from the support head, exposing the seal

assembly. Grasp the seal fi rmly by hand and twist it

on the shaft to break the seal between the bellows and

the shaft. The seal can now be pulled from the shaft.

Also remove the seal gland (56) from the shaft. Place

gland gasket (60) in water. Press seat gaskets (D) and

fl oating seat (E) from the seal gland (56) and seal head

(52).

3. To install new seal assembly, oil the outer surface of

seat gasket (D) and press seat gasket and fl oating seat

assembly (D) and (E) into the seal gland cavity. Also

apply oil to the outer surface of seat gasket and press

seat gasket and fl oating seat assembly into the cavity in

the base of the seal head (52). DO NOT SCRATCH

Figure 5

Figure 6

Figure 4

Loading...

Loading...