11

j. Pull off bearing housings (31) and (33) and bearings

(16) and (18). Note: On oil lubricated pumps shaft

collar (68) will also be removed.

k. Remove bearings from bearing housings.

l. Remove deÀ ectors (40) and casing wearing rings (7).

m. Remove packing (13) and lantern rings (29) or seal

gland (251), gasket (259) and mechanical seal (65).

n. Mark impeller location in relation to pump shaft and

remove by unscrewing shaft sleeves (one right

hand and one left hand thread).

o. If impeller wearing rings are to be replaced remove

all twelve set screws (296) and chisel ring (8) from

impeller (2).

5. REASSEMBLY

The following procedure is for the complete assembly of

the pump. This procedure must be followed for satisfactory

operation. If pump is not completely disassembled, use

only the steps that are applicable.

1. Press impeller wearing rings (8) onto impeller (2)

making sure they are evenly and fully seated.

(Impeller wearing rings are standard on pumps with

8” or larger discharge and optional on smaller units.)

2. Position impeller key (32) on pump shaft (6).

3. Slide impeller onto shaft. Center between shaft

threads.

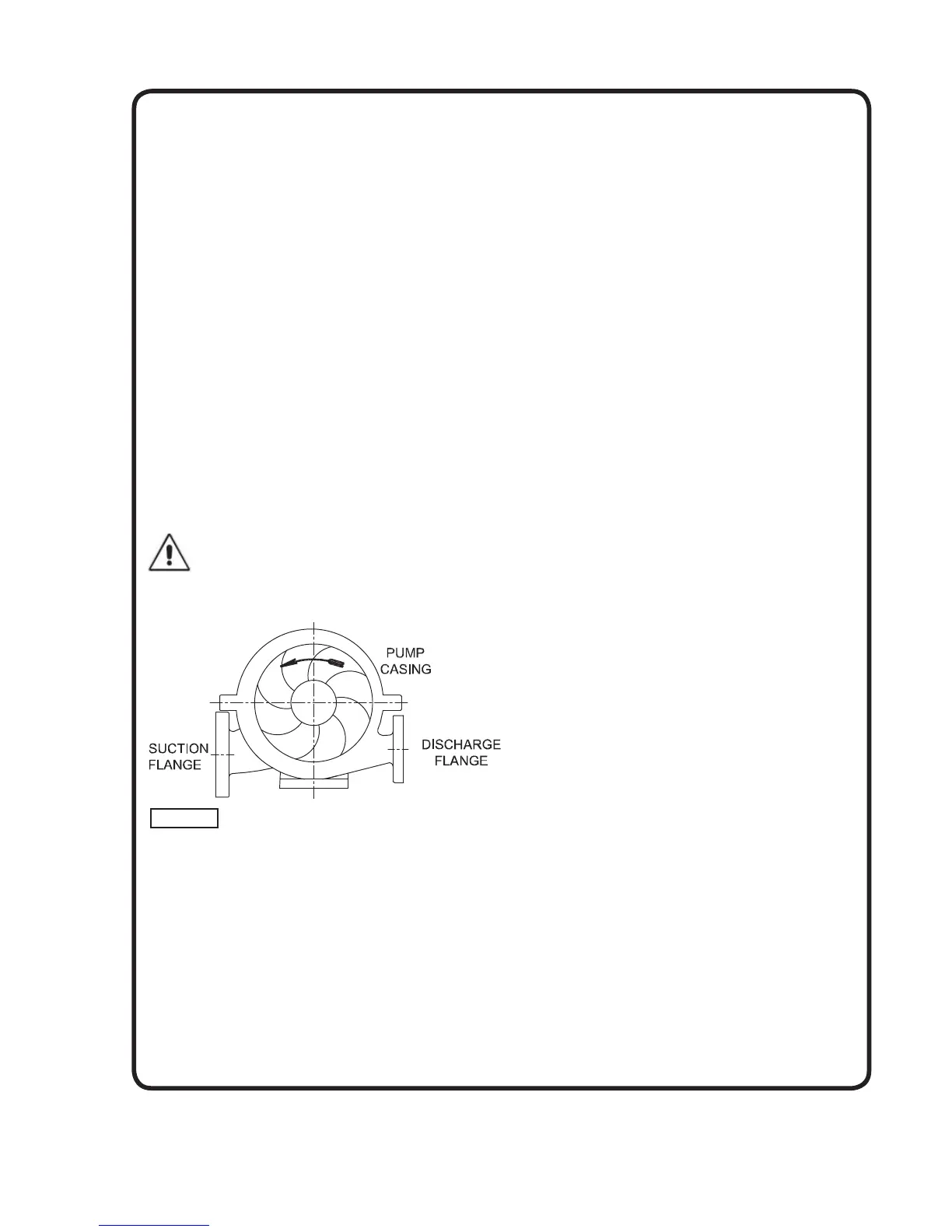

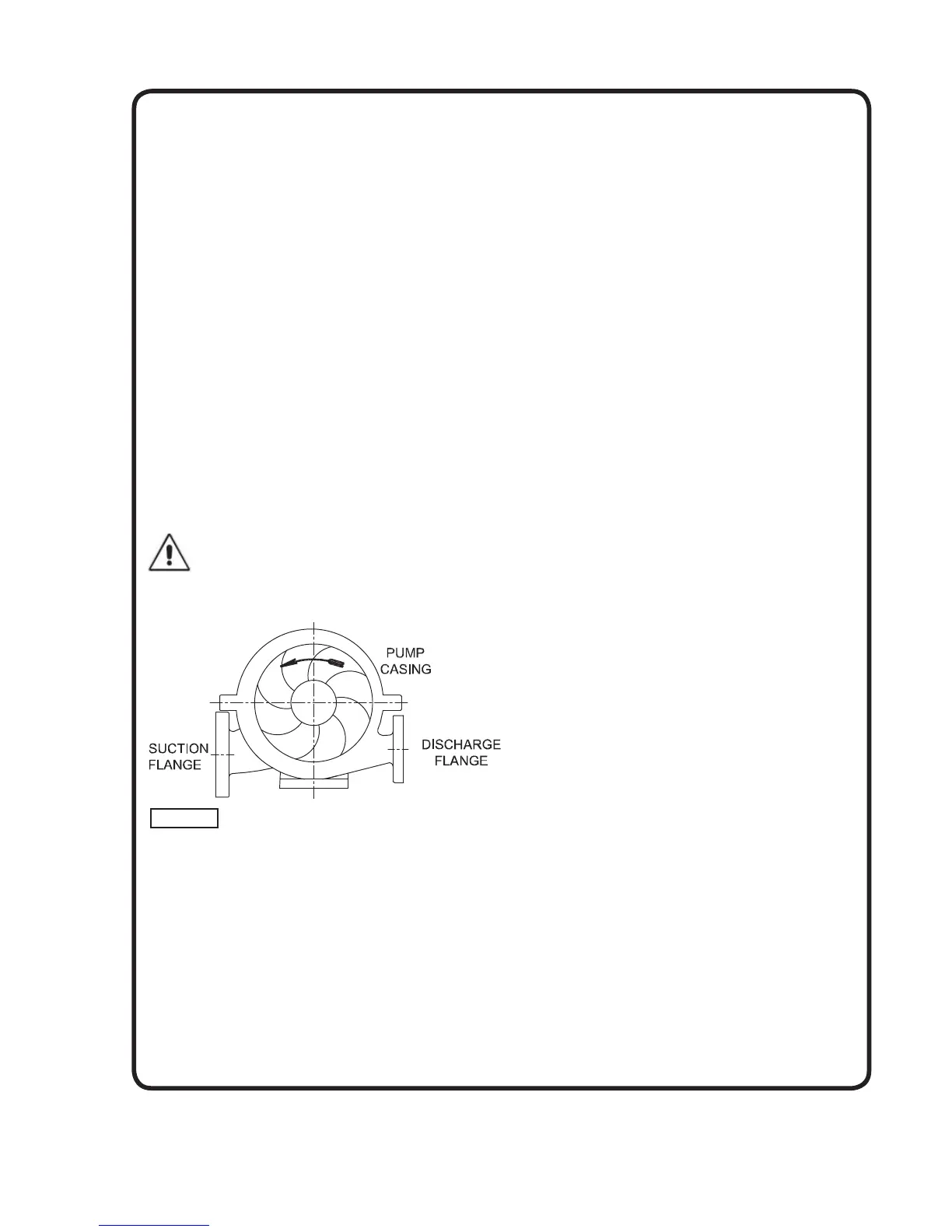

IMPORTANT! - When placed in casing, the

rotational curve of the impeller blades in

relation to the position of the pump discharge

must be as shown in Figure 6.

4. Slide shaft sleeve gasket (38) over shaft and place

one gasket against each side of the impeller.

5. Thread shaft sleeves (14) and (20) onto shaft,

one right and one left hand thread, but do not draw

up to impeller nut.

6. Place lantern rings (29), or seals (65), seal gaskets

(259) and seal glands (251), on the shaft along with

deÀ ectors (40).

7. Press lip seals (47) into bearing housings (31) and

(33) with the retaining spring toward the bearings.

Lip seal must be continually lubricated both during

and after assembly.

8. Slide bearings (16) and (18) into bearing housings

(31) and (33). Press only on the outer bearing race

if required.

9. Place bearing assemblies onto shaft. Press only on

the inner bearing race if required.

10. On grease lubricated pumps, place the lock washer

(69) on the shaft and secure the thrust bearing in

place with a lock nut (22).

For oil lubricated pumps, lock the thrust bearing

in place with two nuts (22). Lock nuts must be

installed so that a groove is created between them.

Press a shaft collar (68) onto shaft and against

the inboard bearing. Place an oil ring (60) in the

groove between the two lock nuts and shaft collar.

11. Press bearing dust cover (123) into bearing cover

(37). Then place gaskets (303), (use only on oil

lubricated pumps) and bearing covers (35) and (37)

on bearing housings and secure with cap screws

(245).

NOTE: On grease lubricated pumps, the grease

¿ tting (207) must match the dowel pin hole in the

bearing housing.

On oil lubricated pumps, the air vent (235) must

match the dowel pin hole in the bearing housing.

12. Position casing wearing rings (7) on the rotating

element and lower the complete assembly into the

lower casing. The tongue on the casing ring must

match the slot in the lower casing.

13. Match bearing caps (41) and (43) to marks on the

casing and position on dowel pins (247) which

extend from the bearing housings. Fasten securely

with cap screws (239).

14. Position impeller in the center of the casing and

tighten both shaft sleeves against the impeller.

15. Position the casing gasket on the lower casing.

NOTE: On pumps with mechanical seals, allow

the gasket to overhand the casing where the

seal gland gasket (259) mates. Trim the excess

prior to tightening the seal gland.

Inspect inside of both casing halves and remove

all foreign objects. Then carefully lower upper

casing (1B) onto dowel pin (246).

16. Place swing bolts (209) in proper positions and

secure the two casing halves together with nuts

(213) and cap screws (215).

For pumps using ring type packing:

Place packing rings (13) over the pump shaft and

slide into stuf¿ ng box. Alternate position of ring

splices 120° apart. Position lantern ring so that seal

water passage is in line with the lantern ring.

When packing is complete, place split gland (17),

gland clips (206), and nuts (210) on swing bolts.

Draw nuts down tight to seat bottom rings of

packing, then loosen nuts to ¿ nger tight for starting.

For pumps using mechanical seal:

Place nuts on swing bolts and tighten. Attach piping

for seal water if used.

17. Be sure all pipe plugs are in place and rotating

element turns freely.

Figure 6

Loading...

Loading...