6

WARNING - Coupling guards must be used to

avoid serious injury to operating personnel.

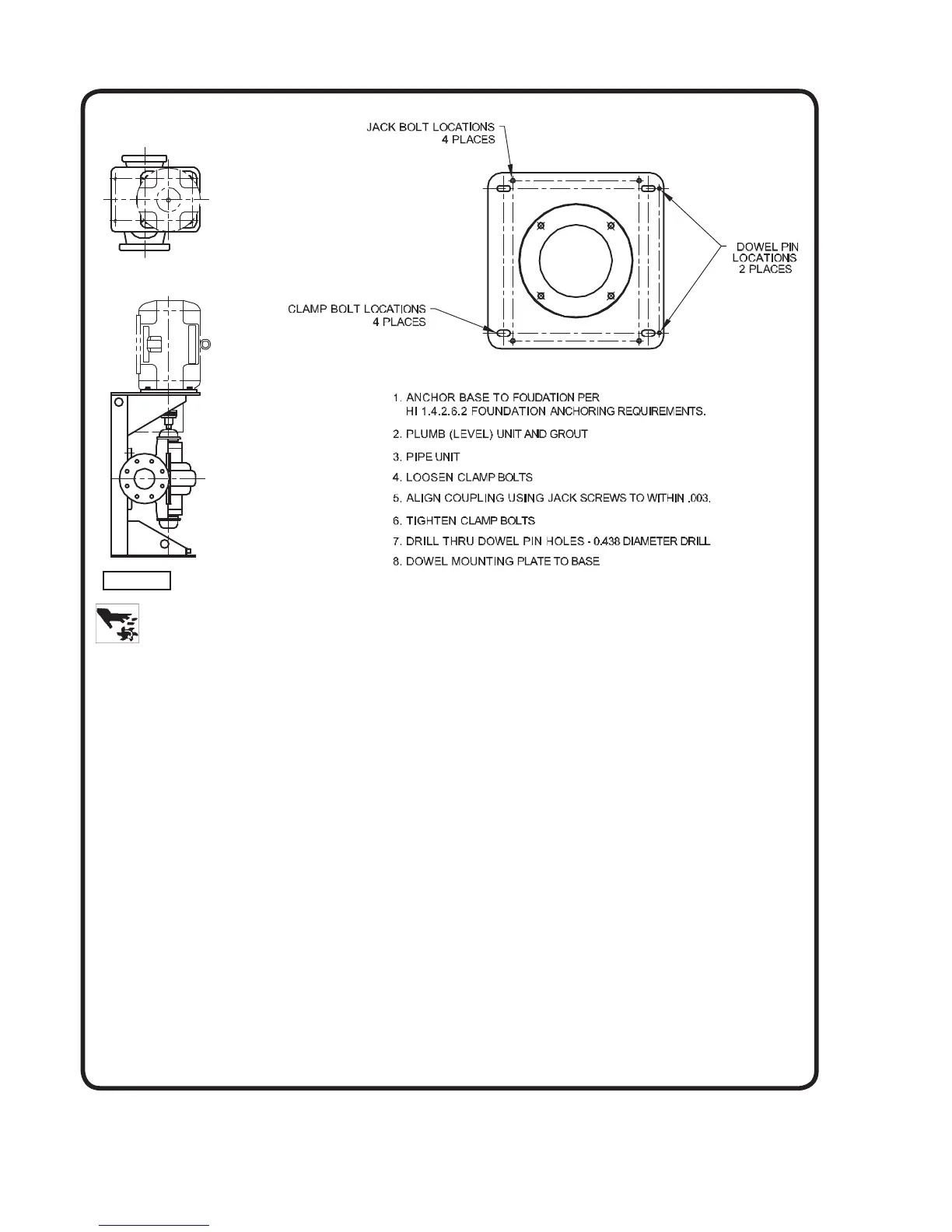

FIELD ALIGNMENT - Vertical Units

To protect the pump and motor during shipment, the motor

and À exible shaft coupling may be shipped unmounted

and must be installed on the pump and properly aligned at

the pump site. Clamp an extender to the pump shaft and

by using a dial indicator, positioned against the ¿ nished

bore of the top plate of the vertical frame, rotate the pump

shaft checking alignment of the pump shaft with the

vertical mounting frame. Use the jackscrews in the base

of the mounting frame or metal shims under the feet of

the pump casing and adjust the pump so that the T.I.R. is

within .004”. Lock jack screws with the jam nuts. The shaft

position in relation to the ¿ nished surface at the top plate of

the mounting frame should be within T.I.R. of .005”.

Install coupling halves on motor shaft and pump shaft but

do not tighten coupling set screws. Position the motor over

the pump and complete the coupling assembly according

to manufacturer’s recommendation, as the motor comes to

rest on the top plate of the vertical mounting frame. Insert

and tighten the motor cap screws.

Using an indicator on both the motor shaft and the pump

shaft, make sure that the shafts are concentric within .004”

and are aligned axially. Tighten coupling set screws.

It is recommended that the motor and pump be dowelled

to the vertical mounting frame when the correct alignment

has been established. Use Loctite on all dowel pins.

5. GROUTING

Grouting compensates for unevenness in the foundation

and prevents vibration and shifting after mounting is

complete. Build a form around the base plate to contain

the grout, and sprinkle area with water to obtain a good

bond. The base should be completely ¿ lled with a good

quality, non-shrinking grout. The usual mixture for grouting

is one part Portland cement and two parts sand with

suf¿ cient water to À ow freely. It is also desirable to grout

the leveling pieces, shims or wedges in place. Foundation

bolts should be fully tightened when grout has hardened,

usually about 48 hours after pouring.

6. PIPING

The pump suction and discharge connections are not

intended to indicate the required suction and discharge

pipe sizes. The pipe diameter must be selected according

to the requirements of the pumping system and

recommended friction losses for the liquid being pumped.

Usually, it is advisable to increase the size of both the

suction and discharge pipes at the pump nozzles to have

minimum acceptable friction loss, suction pipe should

never be smaller in diameter than the pump suction

nozzle. When suction pipe is of larger diameter than the

pump suction nozzle, an eccentric reducer is required to

eliminate possible air or vapor pockets at the pump suction

inlet.

Figure 3

Loading...

Loading...