34

DEPA

®

Air Operated Diaphragm Pumps

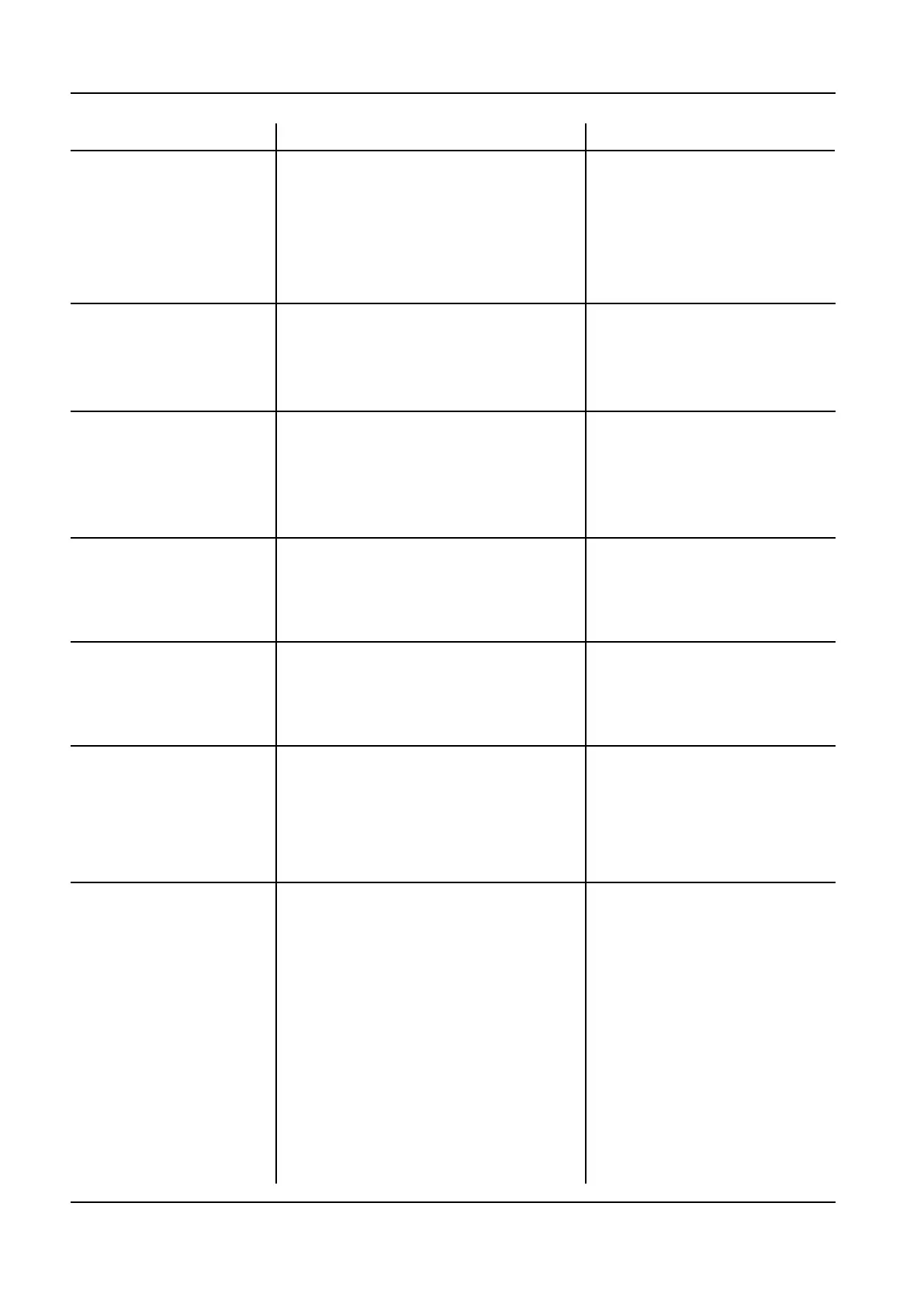

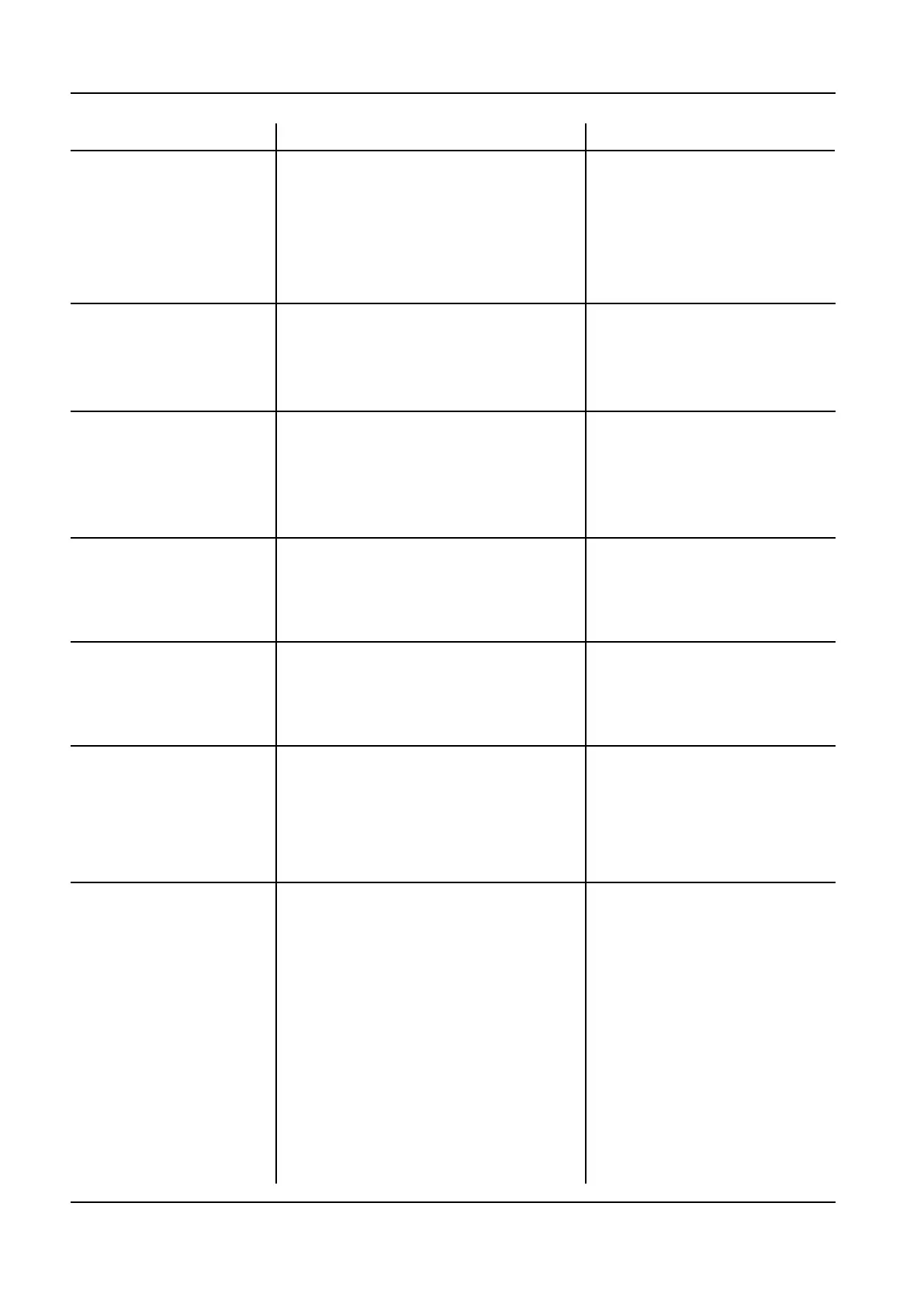

Fault Possible cause Remedy

Pump does not work despite

air supply

Valveballsdeformed

Pump leaking at the clamp

band

PTFE diaphragm cracked a

after short time

Insucientsuctionhead

Pump very loud, crackling

noise

Piston rod hard moving

Muerclogged

Airinletlterclogged

Valveballsstickingto

valve seat

Chemical attack

Mechanical attack

Clamp band cracked

Diaphragm not centred

during assembly

Large solids in product

Compressed air opened with a shock

Valveballandseatleaking

Pump completely dry

Control valve worn

Excessivefeedonthe

suction side

Compressed air too dry

(Instrument air)

Temperature too high

Compressed air dirty

Piston rod run in

Clean or renew

Clean or renew

Loosen, use PTFE balls

instead

Change material

Change material

Replace

Assemble again

Installalter

Install a slow start valve

Replace

Fill suction line

Replace

Install heavier valve balls

Throttling of suction line

Lubricate the air

Cool down

Installalter

Replace

Loading...

Loading...