Safety Information

06/2021 7 / 268

Tool extension cables

Length (m) Length (ft) Part number

8 26.2 6159175810

16 52.5 6159175840

32 105 6159175870

Mounting plates

Mounting plates are not supplied.

Refer to the following guideline drawing numbers available

at https://www.desouttertools.com/resource-centre

.

Model Drawing number

Clamping screw

size

EFD43-8 6159701380 M6 x 20

EFD43-15 6159701380 M6 x 20

EFD43-30 6159701380 M6 x 20

EFD43-45 6159701380 M6 x 20

EFD51-70 6159701390 M8 x 25

EFD51-135 6159701390 M8 x 25

EFD60-175 6159701390 M8 x 25

EFD60-250 6159701390 M8 x 25

EFD80-330 6155482910 M8 x 25

EFD80-450 6155482910 M8 x 25

EFD80-680 6155482910 M8 x 25

EFD80-950 6155482910 M8 x 25

EFDO24-20 6159702760 M6 x 20

EFDO30-80 6159702770 M6 x 20

EFDO40-180 6159702780 M8 x 25

EFDO54-450 6159702790 M8 x 25

Controller range

Only below Multi system can be used to power and drive this

product.

CVI3 Vision 6159326910

CVI3 Vision eSTOP 6159326940

TWINCVI3 6159326970

TWINCVI3 eSTOP 6159326980

CVI3 Function 6159326900

CVI3 Function eSTOP 6159326930

Safety instructions for machine manufacturer

Desoutter should not be held responsible for any injury, acci-

dent or damage which may be the consequence of an incor-

rect installation, modification or start-up, or a use out of the

intended use of Desoutter products, by the customer or a

third party.

Operator protection

This product is aimed at being integrated as a component in a

machine.

It is not a standalone nor a hand held tool, usable as it is.

It is under the responsibility of machine manufacturer to

make sure that:

• Product is properly surrounded by guards to prevent

from any contact at purpose or unintentionally on poten-

tial hot areas on this product.

Example of guard:

• If machine start requires operator to operate continu-

ously a trigger, the Quick Stop function of the controller

is properly connected to this trigger, in addition to the

start device (digital input or network)

Refer to the product information provided with the con-

troller unit to get further details on the Quick Stop func-

tion wiring and set up.

Tool cable installation

The tool cable should be placed to avoid a prolonged contact

with the motor which is the hottest part of the tool.

Although the tool has a thermal protection which switches

off the operation when it has reached a too high temperature,

it is the responsibility of the user to configure the tool to op-

erate within the established maximum temperatures.

The integration of cables on the application must prevent a

continuous contact of the spindle cable from the spindle mo-

tor capable to generate high temperatures.

The integration must respect the recommendations provided

with the cables (included guideline 6159923380).

Installation

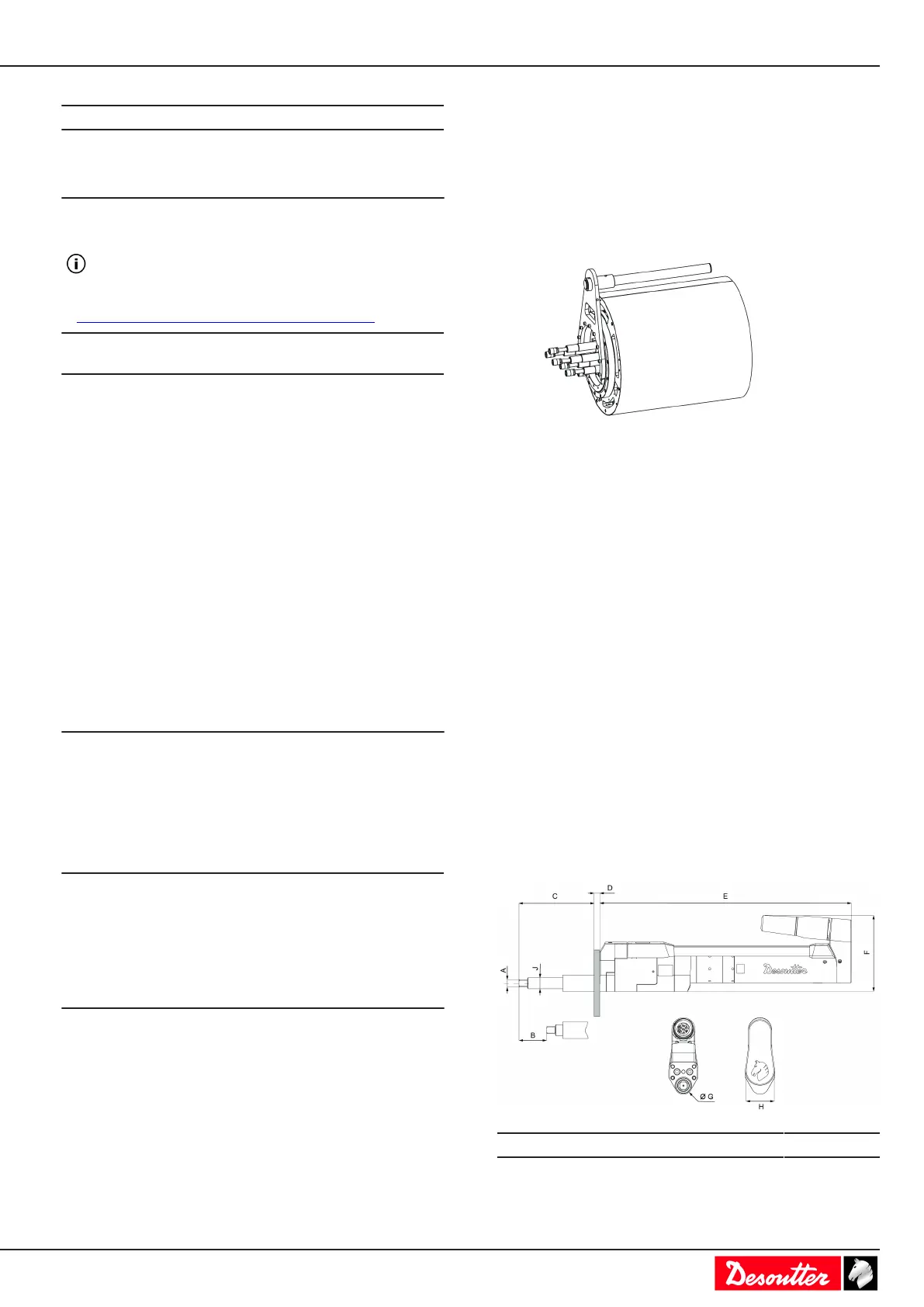

Dimensions (mm)

Model A B C

EFD43-8 9.5 50 76

EFD43-15 9.5 50 76

Loading...

Loading...