15 — ENG

D20247

HOW TO CLEAN THE NOZZLE

If the nozzle becomes clogged with foreign material

such as dirt, excessive pump pressure may develop

and the spray pattern will change. If a nozzle be-

comes partially clogged or restricted, the pump

pressure will pulsate. If this happens, clean the nozzle

immediately using the nozzle cleaning kit supplied with

your pressure washer. The procedure is as follows:

1. Shut off pressure washer and turn off water

supply.

2. Pull trigger on spray gun to relieve any water

pressure.

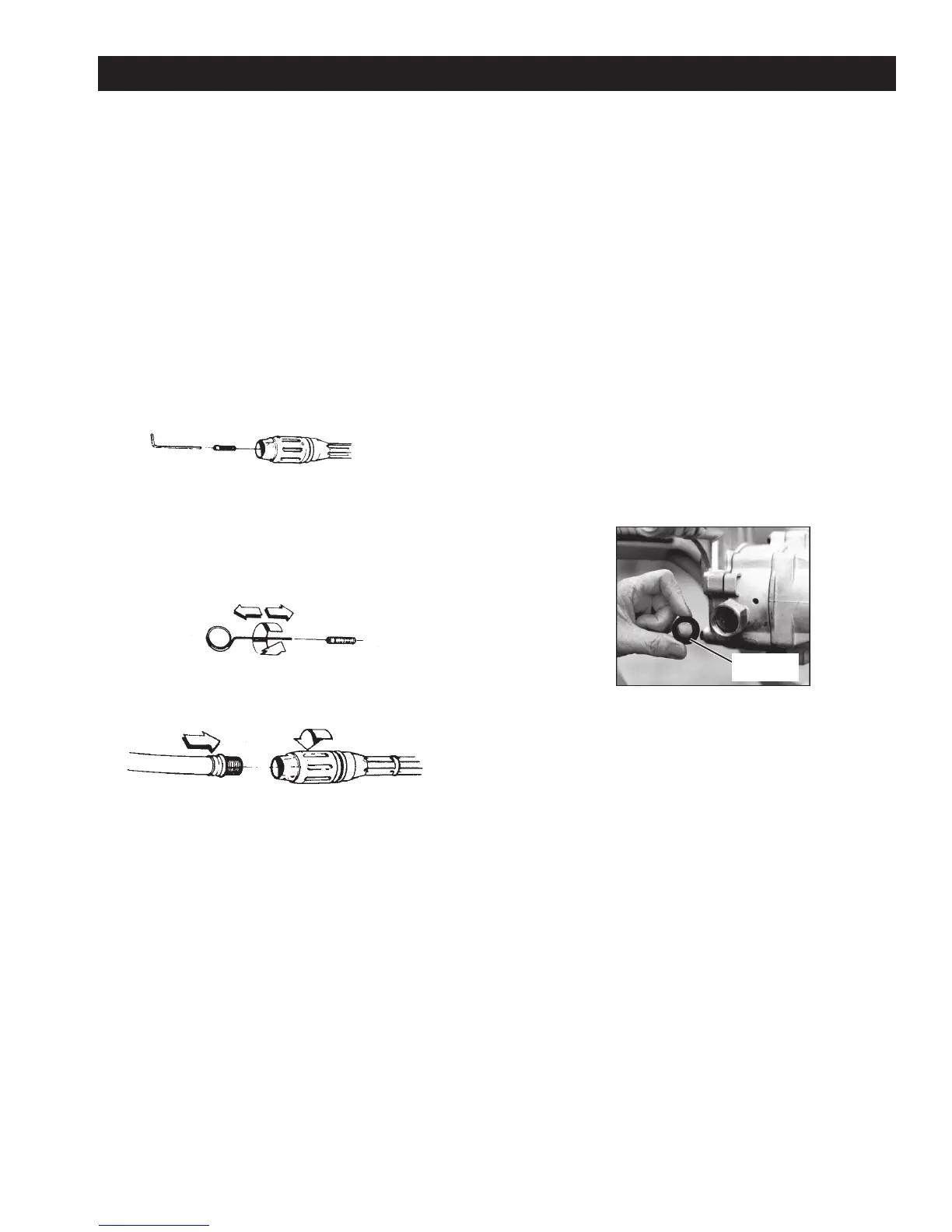

3. Disconnect multi-reg wand from spray gun.

4. Remove nozzle from multi-reg wand with 2 mm

Allen wrench from parts bag.

5. Inspect nozzle for obstructions, grime, or any

foreign matter that could restrict flow of water.

6. Remove any obstructions with nozzle cleaning

tools provided and back flush with clean water as

shown.

7. Direct water supply into nozzle end for 30 seconds

to back flush loosened particles.

MAINTENANCE

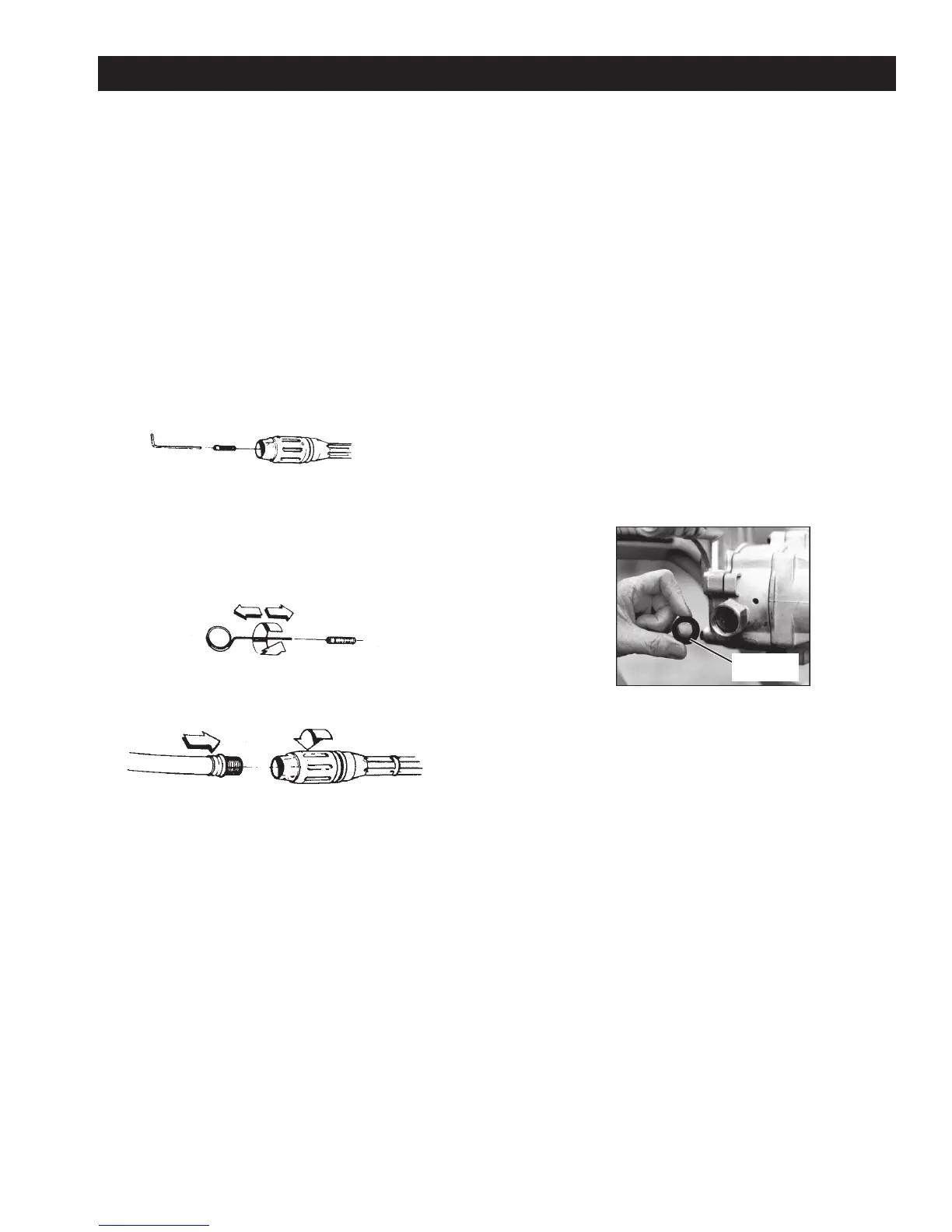

HOW TO CLEAN THE WATER INLET FILTER

This screen filter should be checked periodically and

cleaned if necessary.

1. Remove filter by grasping the end and removing it

from water inlet of pump.

2. Clean filter by flushing with water on both sides.

3. Install filter into water inlet of pump.

screen

filter

8. Take this opportunity to inspect wand for obstruc-

tions. Back flush wand if obstructions are seen.

9. Reassemble nozzle to wand. Tighten securely to

prevent leaks.

10. Reconnect multi-reg wand to spray gun and turn

on water supply.

11. Start pressure washer and test spray pattern. See

How To Use Wand in the Operation Section.

12. If the spray pattern is still incorrect, replace multi-

reg wand.

Loading...

Loading...