14 — ENG

D20247

WHEN DOING MAINTENANCE, YOU MAY BE EXPOSED TO HOT SURFACES, WATER PRESSURE,

MOVING PARTS, OR FIRE RESULTING IN DEATH. BEFORE PERFORMING ANY MAINTENANCE OR

REPAIR, DISCONNECT SPARK PLUG WIRE, LET ENGINE COOL AND RELEASE ALL WATER PRES-

SURE. THE ENGINE CONTAINS FLAMMABLE FUEL. DO NOT SMOKE OR WORK NEAR OPEN

FLAMES WHILE PERFORMING MAINTENANCE.

To ensure efficient operation and longer life of your pressure washer, a routine maintenance schedule should be

prepared and followed. The following routine maintenance schedule is geared to a unit in a normal working

environment. If necessary, the schedule should be modified to suit the conditions under which your pressure

washer is used. The modifications will depend upon the hours of operation and the working environment. If the

pressure washer is in an extremely dirty and/or hostile environment, it will require a greater frequency of all

maintenance checks.

MAINTENANCE

ENGINE

1. Consult Engine Owner's Manual for manufacturer's

recommendations for any and all engine

maintenance.

PUMP

The DAPC pump on your pressure washer was

shipped from the factory with oil. The oil in your pump

must be changed every 50 hours.

1. Run engine until it runs out of fuel. Otherwise, fuel

can leak out, creating a fire/explosion hazard,

when you tip engine.

2. Disconnect spark plug wire and keep it away from

spark plug.

3. Drain engine oil. Refer to engine owner's manual

for correct procedure.

Used oil is a hazardous waste product.

Dispose of used oil properly. Do not discard

with household waste. Check with your

local authorities for safe disposal/recycling

facilities.

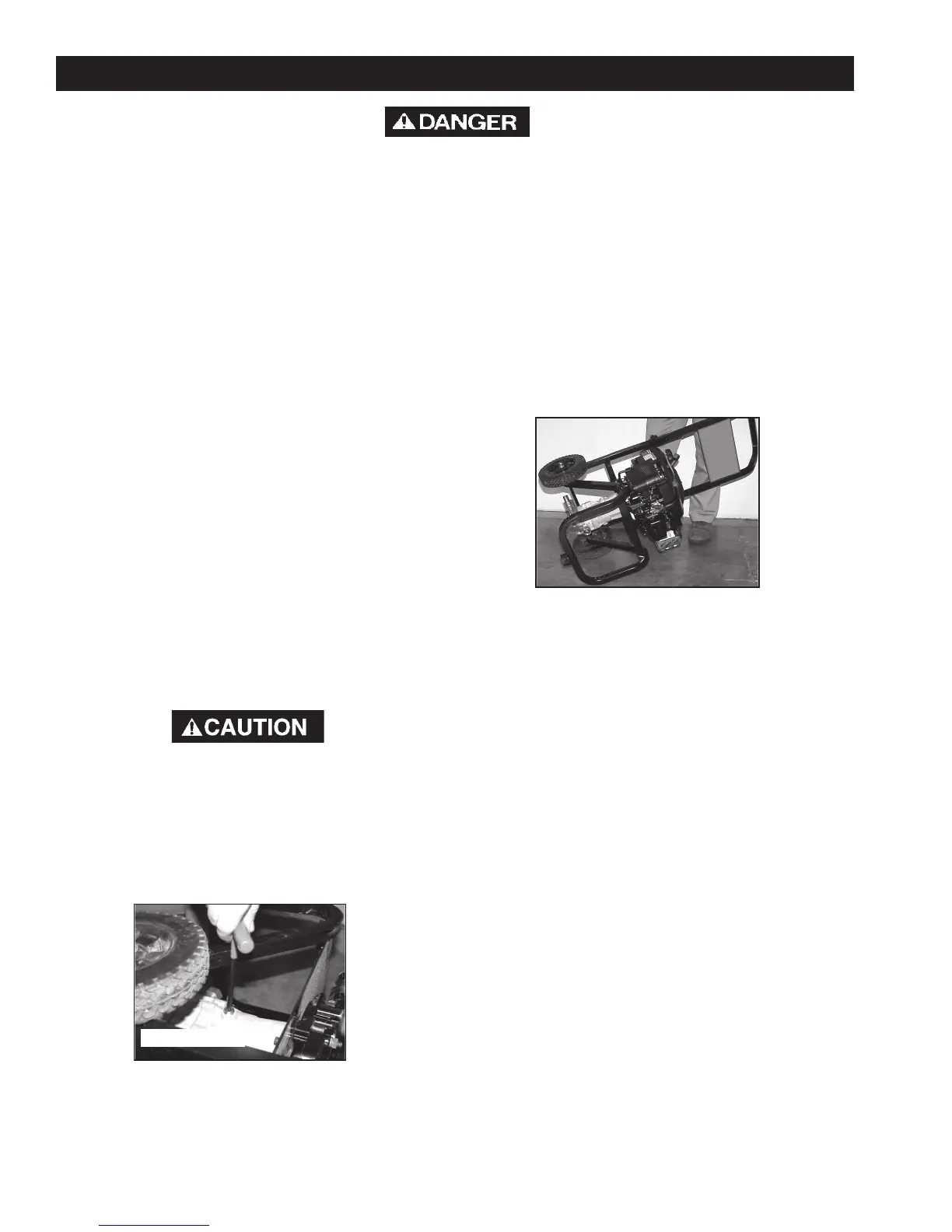

4. Using a 5/16" Allen wrench remove pump oil drain

plug.

5. Tilt unit and drain pump oil into appropriate

container.

6. Fill pump with 10 ounces of R&O 150 oil. NOTE:

If unable to find R&O 150 oil, use 30W non-

detergent oil.

7. Replace oil drain plug and tighten securely.

8. Refill engine with oil and fuel. Refer to engine

owner's manual for correct procedure.

Oil Drain Plug

Loading...

Loading...