Page 6 SB-6-156-O

A Properly Piped Shop Of Prime Importance for a

Premium Finish.

The bottom line in finishing is a quality paint job. Though on the

surface it may not seem a significant factor in your being able to

turn out a quality paint job, the plumbing of your shop air lines is

very important. Correct installation is necessary for the proper

performance of your equipment - for an uncontaminated air

supply and for sufficient pressure to your spray gun.

Correct airline piping is so important that this one factor alone can

reduce contaminates in your air supply up to 75%*. Reducing con-

taminates to the filter also reduces the frequency of filter replace-

ment, maintenance, and of course, reduces the risk of contami-

nates to the paint supply.

Even the size of the pipe is critical. Did you ever have only 60 or 70

pounds of pressure at your spray gun when your compressor

should deliver 100 pounds? Using pipe that is too small in diam-

eter can cause this pressure drop.

For example, if an air compressor delivers 100 psi through a 100 ft.

pipe, 1/2" in diameter, there’s greater pressure drop than if a 3/4"

diameter pipe were used.

The following chart will help reduce pipe pressure drop.

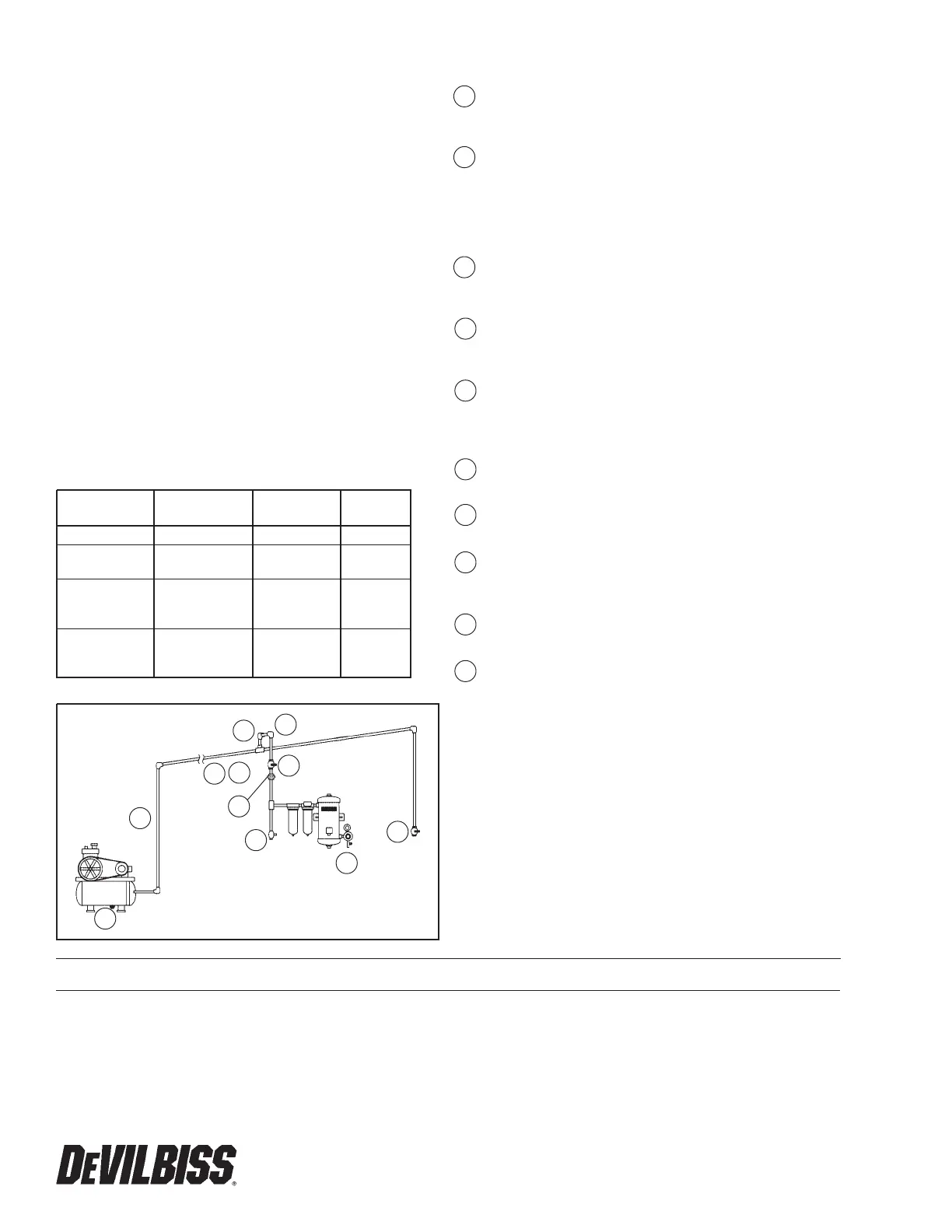

Minimum Pipe Size Recommendations

Compressor Compressor Main Min. Pipe

Size Capacity Air Line Diameter

1-1/2 and 2 HP 6 to 9 CFM Over 50 ft. 3/4"

3 and 5 HP 12 to 20 CFM Up to 200 ft. 3/4"

Over 200 ft. 1"

5 to 10 HP 20 to 40 CFM Up to 100 ft. 3/4"

100 to 200 ft. 1"

Over 200 ft. 1-1/4"

10 to 15 HP 40 to 60 CFM Up to 100 ft. 1"

100 to 200 ft. 1-1/4"

Over 200 ft. 1-1/2"

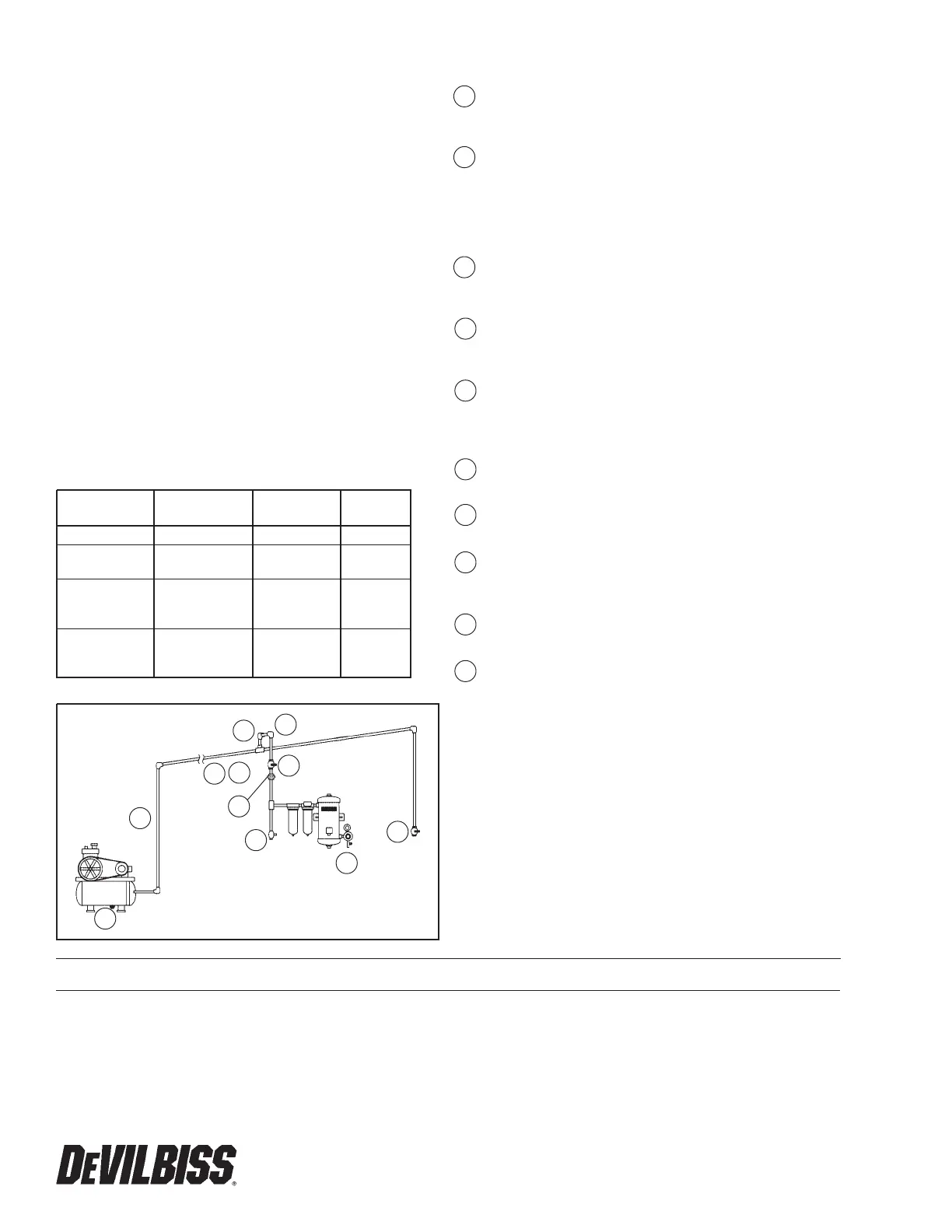

Body Shop Air Line Plumbing Guide:

After leaving the air compressor, air line pipe goes straight up

the shop wall as high as possible. This helps prevent any wa-

ter from leaving the compressor and traveling through the pipe.

Horizontal pipes should slope back towards the compressor at

least 4” per 50 ft. As warm air leaves the compressor, it cools

and thereby condenses as it travels through the pipe. This wa-

ter vapor, a problem in itself, also can cause scaling and rust

inside the piping. The backward sloping of the pipe helps push

these contaminates toward the compressor drain.

Take-off comes from the top of the main air supply line at each

air drop. This reduces the risk of water and other contaminates

from traveling down the drop into the water separator.

Pipe diameter must be of sufficient size for the volume of air

being passed as well as the length of pipe used. This will

minimize pressure drop.

First air drop should be at least 25 ft. from the compressor

although 50 ft. is optimum. This allows the compressed air to

cool to room temperature so any condensation can occur

before it gets to the water separator.

Shut-off valve is installed before the point of use filter. This

allows air to be shut off for filter maintenance.

Pipe union installed before DAD-500 allows easy installation

and removal of the air drying system.

Point-of use filter (not shown) attaches to spray gun, order

HAF-507. Strongly recommended for eliminating any remain-

ing contaminates.

Drain Valves - The daily draining of the system at each outlet

disposes of the contaminants that build up in the air supply.

Drain the compressor trap daily if equipped with a manual drain.

Proper maintenance of the air compressor can reduce airborne

contaminants such as particules and oils, and reduce heat and

|operating cost. Check air filters, oil level and perform regular main-

tenance per operators manuals.

Guidelines To Piping Your Shop

• Pipe slopes upward - recommend 4” rise in 50 ft.

• Minimum 25 ft. to first outlet (50 ft. optimum)

• Pipe size (see chart)

• Shut off valve before filter

• Drain daily

1

2

10

4

3

6

5

9

9

7

8

1

2

3

4

5

6

8

9

10

7

1/06 ©2006 Inc. All rights reserved. Printed in U.S.A.

WARRANTY

This product is covered by DeVilbiss' 1 Year Limited Warranty.

DeVilbiss Worldwide Sales and Service Listing: www.devilbiss.com

Industrial Finishing

DeVilbiss has authorized distributors throughout the world. For

technical assistance or the distributor nearest you, see listing below.

U.S./Canada Technical Service Office:

195 Internationale Blvd., Glendale Heights, IL 60139

Toll-Free Telephone: 1-888-992-4657 (U.S.A. and Canada only)

Toll-Free Fax: 1-800-368-8401

DeVilbiss Automotive Refinishing

DeVilbiss has authorized distributors throughout the world.

For equipment, parts and service, check the Yellow Pages

under “Automotive Body Shop Equipment and Supplies.”

For technical assistance, see listing below.

U.S./Canada Customer Service Office:

1724 Indian Wood Circle, Suite J-K, Maumee, OH 43537

Toll-Free Telephone: 1-800-445-3988 (U.S.A. and Canada only)

Toll-Free Fax: 1-800-445-6643

Loading...

Loading...