FIG, 1 FIG, 2 H FIG 4

B

\

c

I J

Trim up to vert_co_surface&

Tml_agede sudaces verticole&

Cortes haste supedic_es verticoles

FIG, 5

Trims odd angled corners leve than or

greater then 90'.

Taillage dangles speciau× nf_r_urs ou

sa_rieurs _ 90'

Cortes de extremco en angu_omenor_

o r_yeres a _°.

FIG 8

N 1} .....

........ ....,>)

a ?:?: i ................

FIG 10

FIG, 12 F_G, 14 FIG 16

Sub-ba_ rss!_n turned over.

Seve Lase est men:re re:same

Sub_ se demuestra a! rests.

{4,8 mm)

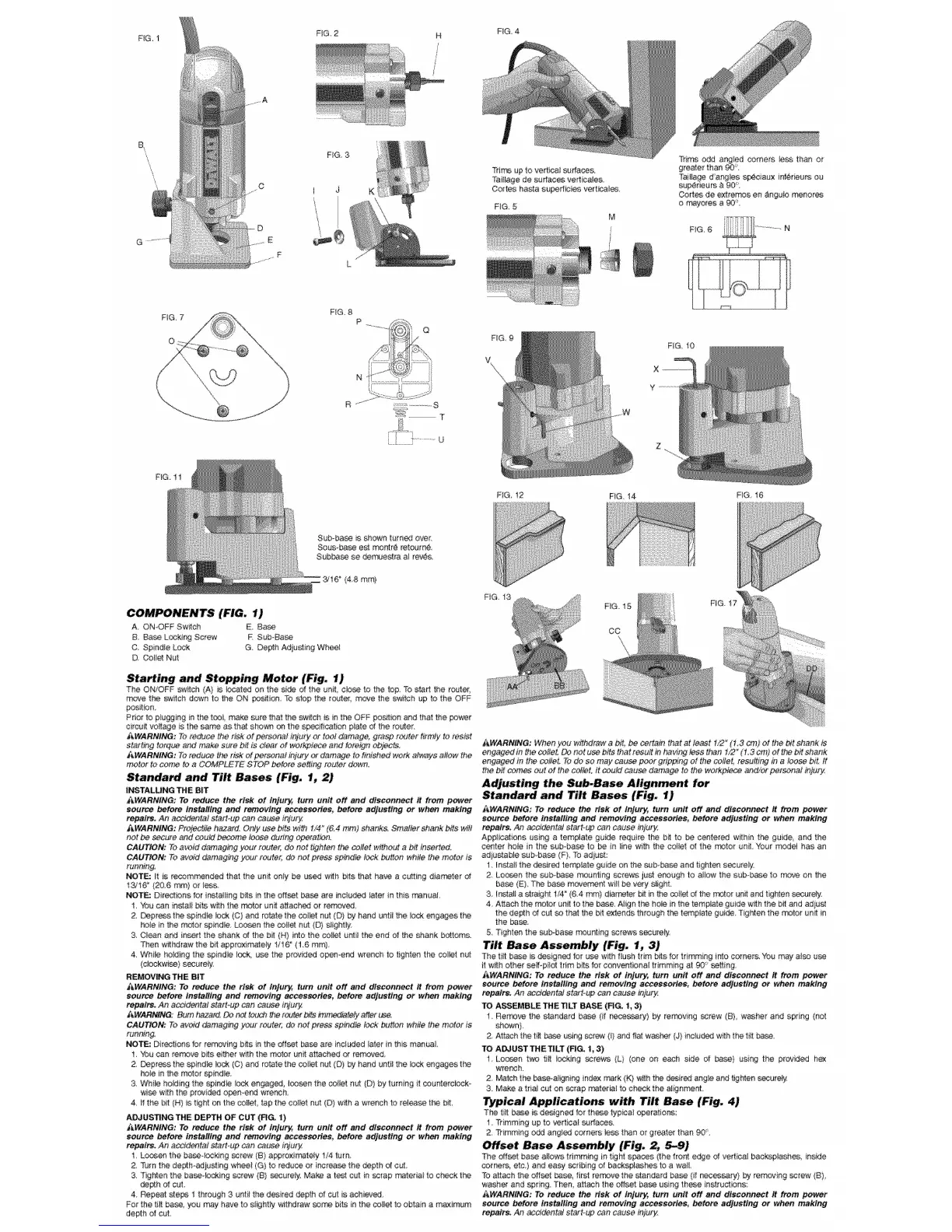

COMPONENTS (FIG. 1)

A, ONOFF Sw_tch E Base

B. Ba_ LoskJnf_Screw R Sub-Base

C, Spindle Leak G. Depth Adjuring Whee_

D, Colfet Nut

Starting and Stopping Motor (Fig, 1)

The ON7OFF _wilch {A) _sbcoted on the side of the un_, ci_ve to the top. Tostart the router_

move the swr_ch down to the ON _sition, To stop the raster, rseve the s_atch up to the OFF

posit©n,

Prior to ptugging in the too_ make sure that the switch is in tee OFF posit©n and that the powe_

circuit voyage is t_ same as th_ shown on the specif_ca_on plate of the router.

J_WARNING; To re_ce the fisRet perser_ injury or ted _mage, 9fa_ rc_der hrmJy to resist

atatt#_g tarq_ &nd make sure bit _sdea_*et wovkpiece and tore_gnobjects.

_WARNING: To reduce the risk of personal ihiuP/ or dar_ge to f_vshed work a_'w_ysallow the

motor to come to a COMPLETE STOP he.re se_ router down,

Stan_ and Tilt Bases (Fig. 1, 2)

INSTALLING THE BIT

Z_WARNING: To reduce the risk of Injury_ turn Unit Off and disconnect # from power

sour_ before installing and removing accessories, before adjusting or when making

repairs. An aas_dentat start..up can _use ie/u_y.

AWARNING: Prelec_jle h_anJ, Only use bits wi_ 1/4_(BA nr}m)shank& Smd_r shank bits wilt

not _ secure and ceutd b_ome levee du_ing epees:ion.

CAUTION: To avoid damaging }_ourreute_: de eat tighten the co#at without a bit inserted.

CAUTION: To avoid damagieg y_f r_tet, do not prove sp_ndtef_k bu#on wh#e the nora{ ts

funnlng_

NOTE; it is recommended that the un_ only be used w_h bits that haue a cutting diameter of

t3/lB _(206 ram) of fee&

NOTE: D}rectk*ns for ivetalling bits in the of:set ba_ are instu_d later in this rranual,

1.You ca_ in,all bi_ with the motor un_ attached or remov_

2.,Depr_S the sptndle ©ck (O) and rotate the cone: as: (D} by hand until _e Io_ engages the

ho_ein the mcto_ splndte. Learn tee ca_iet nut (D) slight{y:

3 Ci_n arid veer: the shank of the bit (H) into the co_et unti_ the end of the _'_ank be:toms.

Then w_hdraw the bit apprexima_eiy 1/16_ (16 ram)

4 While hoidmg the sp_nd_elock, use the provided open-end wrench to tighten the col/e: nut

(cbckwlse) s_urely.

REMOVING THE BIT

_&WARNL_tG: To reduce the risk' of lr_ur_ turn unit off and disconnect it from power

source before installing and t_'noving accessories, before adjusting or when making

repairs. An aaside_taJ start-gp can _3use iGlu<y

/__WARNI._: Bum h_#_d. Do t_ teu_ ff_'aroute_b#s #nm_iate#/ at:el yea.

CAUTION: Toavdd damaging your r_teL _ not prove spindle _ck button white the motor is

Fdat}a?g_

_TE: Directions for rer-novtrg bits in the off_! _ a_e included tater in this manual

! You ca_ re_'r_ve bits e{ther w_ththe _tor ue_ attached or removed

g. Depress the spmdle _ask(C) and rotate the cooer nut (D} by hand until the #ck engages the

holeinthem_o{ spindle,

3 While he#rag the spnd_ iO_ engaged I_sen the col_et nut (O) bytummg It counterciock

wi_ w_h the provided o_mend wrench,

4. If the bit (H) _stight er_the _llet tap the sotIet nut (D) w_h a wrench to re_ t_ #_t.

ADJUSTING THE DEPTH OF CUT (FIG, 1)

_&WARNING: To reduce the risk of tnJurJ4turn unit off and disconnect# from power

scuttle before instal/#_g and removing accessories, before adjusting or when making

rei_lr_ An aveidef_tal start-up can cause injury

1 Leveen the base4ockmg sorew (B) a_roxirvetety !/_ turn.

& Turn the de_h adjusting whee{ (G) te redu_ or increa_ the depth of cut

3 Tighte_ the baseoiockmg screw (B) _urety, Ma_ a te_ cut in scrap material to check the

_h of cut.

4 Repeat _e_ t through 3 until the d_ired depth d cut is achieved

FO_'the tilt ba_, you may have to st_htIy withdraw _ bts i_ the ceiiet to obtain a maximum

depth of cut.

FiG. 15

CO

/_WARNING: When yea withdraw a bit, be _erta#_ that at feast 1/2"(t,3 cm) at the t_t shank is

engaged in _e asfle_ _ not use bits that resuR in havir_ _easthan f,_ (I.3 crn) et tk_ bit s_ank

engaged it} the co%at.To do so may _ase peo_ g#p_ng ot the cel_e_ _esuiting in a loose bit. it

the bit _re_ eu_d the sollet, it asukJ cease dan}age te the workplace &,}d/_ personal injur_

Adjusting the Sub-Base Alignment for

Standa_ and Tilt Bases (Fig. 1)

_WARNiNG: To reduce the risk of injury, turn unit off and disconnect it from power

source before installing and removing acceseories, before adjusting or when making

repairs. Ae accidental star,up can cause injut_

AppI_catass using a template guide require the b_ to be cente_'ed within the guide and the

center hole in the suboba_ !o be in _inewith tl_e co_et of the motor un_. Your _del has an

adducable eub-ba_ (F} To adjast:

1 I_alf the desir_ template guide o_ the sub-_ and tighten secUre_

2 Lo_n the suboba_ moaning screws just enough to allow the sub-base to m©ve on the

ba_ (E) The base movement witl _ very sight

3 fns_a#a straig_ 1/4" _64 ram) d_ameterbit in tee _it_ d the rotatorun_ and tighien _ure_.

4. Attach the rnoto_ unit to the base, Aiign the hole in the :empire guide with the bit and adiust

the depth of cut so treatthe _t extends through t_ template guide Tighten the _ter unit in

the _.

5i Tighten the su_ba_ mount _g _fews ssoure#y

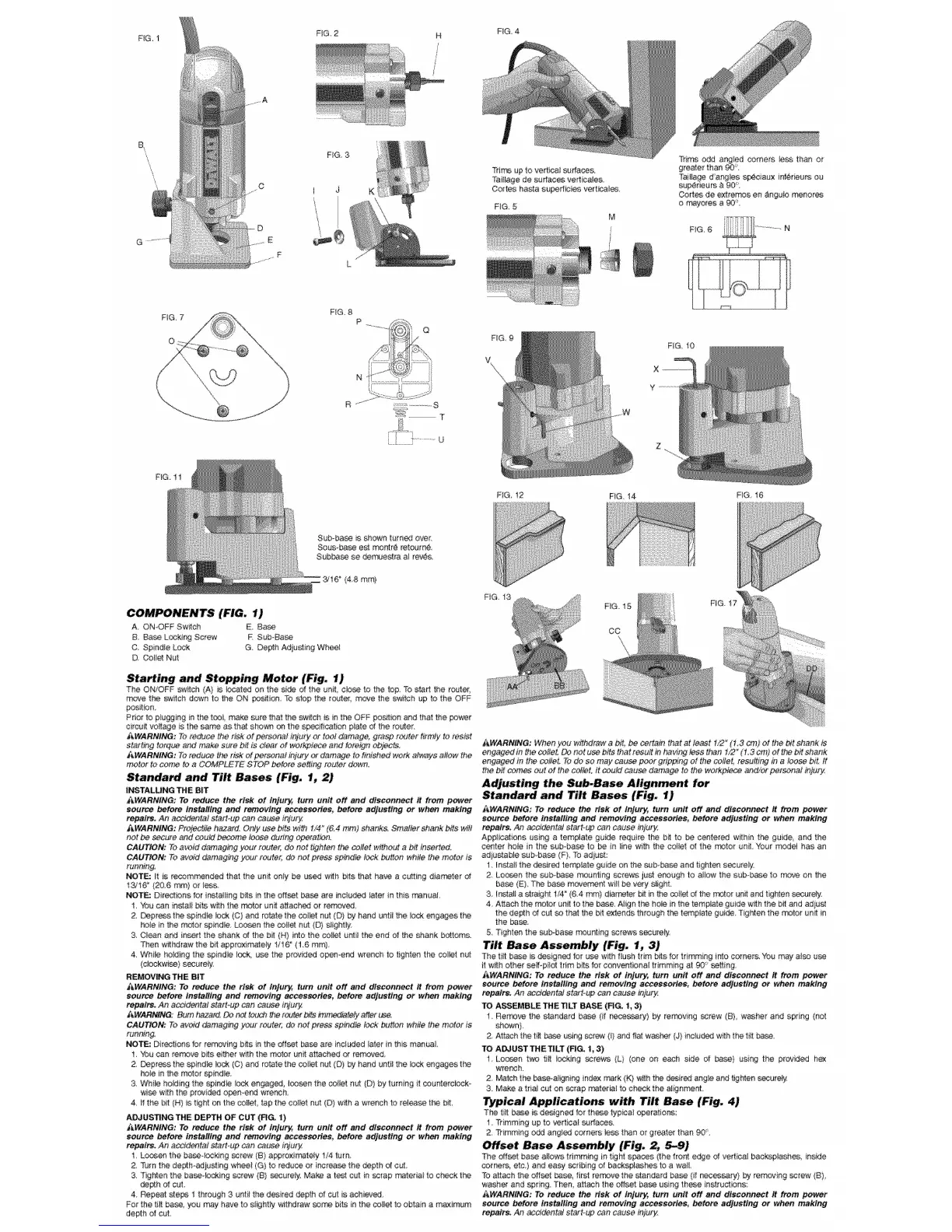

Tilt _se Assembly (Fig. 1, 3)

The ti_t base is designed for uae w_lhflush trim bits for trimming into comers, You may also u_

it w_h other self-pi/_ trim b_s for conventional trimming at _ asking,

_WARNING: To reduce the risk of injury, turn unit off and disconnect it ft_m power

eeurce before tnetalilng and removing a_essoriee, before adjusting or when making

repalre. An asddental starto_t_can cause L_'ury.

TO AS-SEMBLE THE TILT BASE (FIG. 1, 3)

I Remove tt_ s_andard base (it nece_ry} by rer_yvi_g _rew (B} washer and spring (not

shown}

2 At_ch the h_ _se using _rew (t) and fiat washer {J) {r_tuded with the ti_tbase

TO ADJUST THE TILT (FIG. I,3)

1 Leaven two ti_ k._ckJngscrews (L) (one on eash side of _se} us{_ the provk_ed h_

wrench.

2 Match the base-aligning index mark (K) w_h the d_red angle and tighten securety

g Make a triat cut on ssrap m,eternal to eheekthe aI_n_nt

fypical Applications with Tilt Base (Fig. 4)

The ti_ base _ designed for these _ypiea/operatior_s_

1, Trimming up to sertical _Jda_s+

2. Trimming odd angled c_ners _evethan or greater than 90 _,

Offset Base Assembly (Fig, 2, 5-9)

The oftvet ba_ allows trimming in tight s_ (the fror_ edge of verhca/backsp_shve, inside

comers, etc.) ar_ easy _ribir'_3 of backsplashes to a walt

Toattach the at:set base, first remove the standard base (if nec_ry) by removing sorew (B}

washer and spring. Then att_h the offset ba_ using these instructions:

AWARNING: To reduce the risk of injury, turn unit off and disconnect it from _wer

source befot'e installing and removing before adjusting or when making

repairs. An acddental start-_ can cause it}jUf_4

Loading...

Loading...