ENGLISH

8

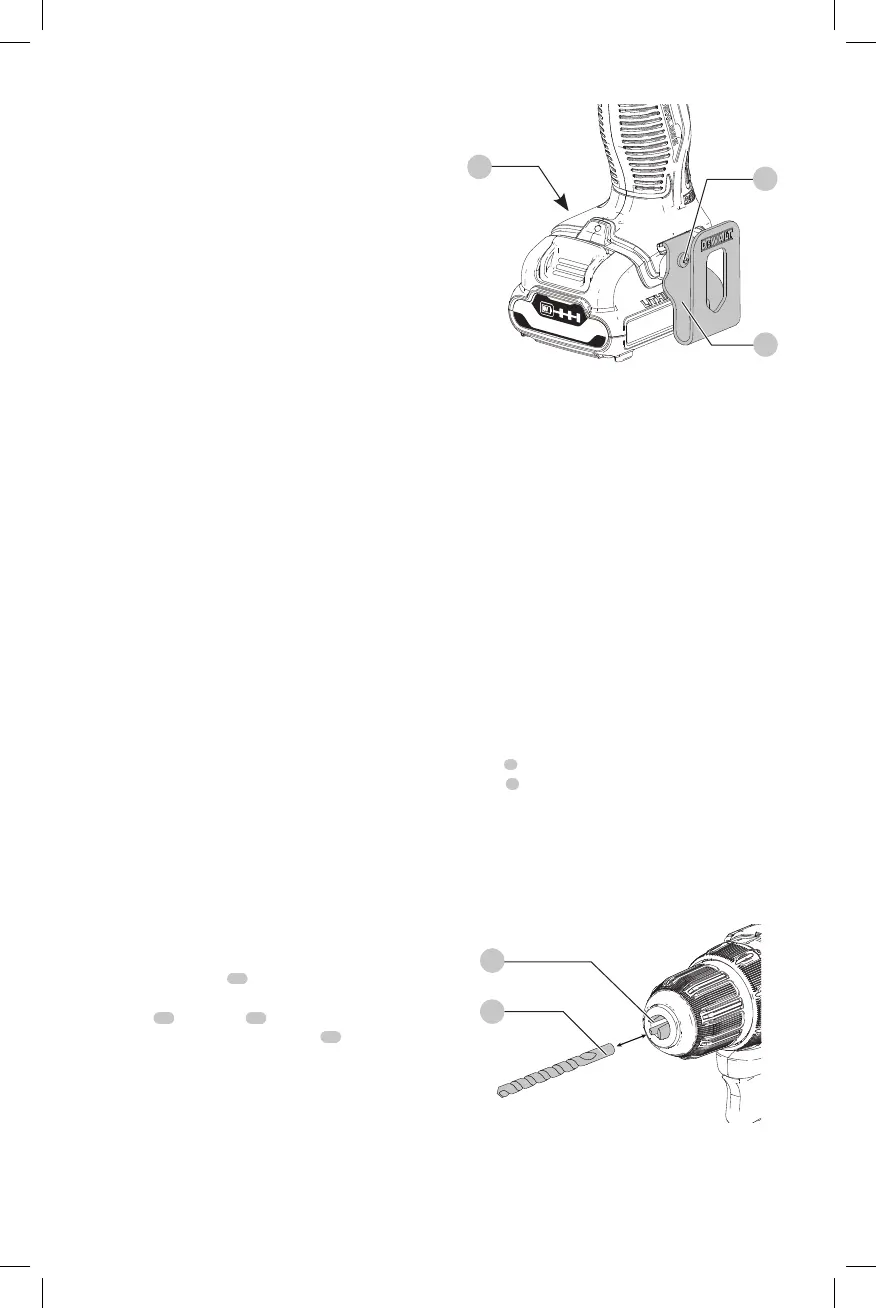

Installing a Bit or Accessory into a Keyless

Chuck (Fig. C)

WARNING: Do not attempt to tighten drill bits (or

any other accessory) by gripping the front part of the

chuck and turning the tool on. Damage to the chuck

and personal injury may result. Always lock off trigger

switch and disconnect tool from power source when

changingacces sories.

WARNING: Always ensure the bit is secure before

starting the tool. A loose bit may eject from tool

causing possible personalinjury.

To insert a drill bit or other accessory, follow thesesteps.

1. Turn tool off and remove battery pack.

2. Grasp the black sleeve of the chuck with one hand

and use the other hand to secure the tool. Rotate the

sleeve counterclockwise far enough to accept the

desiredaccessory.

3. Insert the accessory about 3/4" (19 mm) into the

chuck

9

and tighten securely by rotating the chuck

sleeve

8

clockwise with one hand while holding the

tool with the other. Your tool is equipped with an

automatic spindle lock mechanism. This allows you to

open and close the chuck with onehand.

Be sure to tighten chuck with one hand on the chuck sleeve

and one hand holding the tool for maximumtightness.

To release the accessory, repeat steps 1 and 2above.

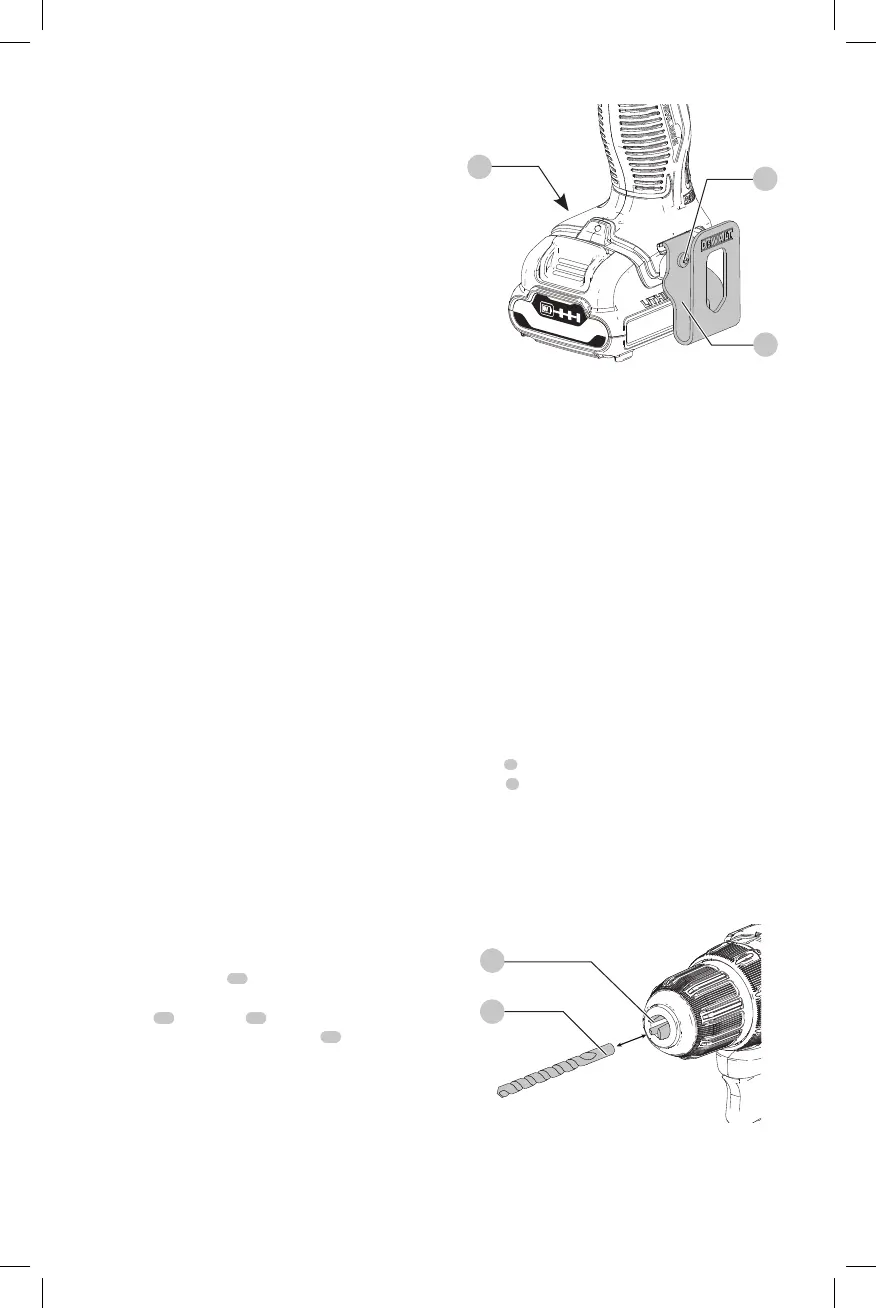

Belt Hook and Bit Clip (Fig. B)

Optional Accessory

WARNING: To reduce the risk of serious personal

injury, ONLY use the tool’s belt hook to hang

the tool from a work belt. DO NOT use the belt

hook for tethering or securing the tool to a person or

object during use. DO NOT suspend tool overhead or

suspend objects from the belthook.

WARNING: To reduce the risk of serious personal

injury, ensure the screw holding the belt hook

issecure.

IMPORTANT: When attaching or replacing the belt hook or

bit clip, use only the screw

12

that is provided. Be sure to

securely tighten thescrew.

The belt hook

11

and bit clip

13

can be attached to

either side of the tool using only the screw

12

provided, to

accommodate left- or right- handed users. If the belt hook

or bit clip is not desired at all, they can be removed from

thetool.

To move the belt hook or bit clip, remove the screw that

holds it in place then reassemble on the opposite side. Be

sure to securely tighten thescrew.

ASSEMBLY AND ADJUSTMENTS

WARNING: To reduce the risk of serious personal

injury, turn unit off and remove the battery pack

before making any adjustments or removing/

installing attachments or accessories. An

accidental start-up can causeinjury.

Intended Use

These drills/drivers/hammerdrills are designed

for professional drilling, screwdriving and

hammerdrillingapplications.

DO NOT use under wet conditions or in presence of

flammable liquids orgases.

These drills/drivers/hammerdrills are professional power

tools. DO NOT let children come into contact with the tool.

Supervision is required when inexperienced operators use

thistool.

Fig.B

12

11

13

Wall Mounting

DCB107, DCB112, DCB113, DCB115, DCB118, DCB132

These chargers are designed to be wall mountable or to

sit upright on a table or work surface. If wall mounting,

locate the charger within reach of an electrical outlet,

and away from a corner or other obstructions which may

impede air flow. Use the back of the charger as a template

for the location of the mounting screws on the wall. Mount

the charger securely using drywall screws (purchased

separately) at least 1” (25.4 mm) long, with a screw head

diameter of 0.28–0.35” (7–9mm), screwed into wood to an

optimal depth leaving approximately 7/32” (5.5 mm) of the

screw exposed. Align the slots on the back of the charger

with the exposed screws and fully engage them in theslots.

Fig.C

8

9

Loading...

Loading...