16

SECTION E: CORDLESS CIRCULAR SAW DW007

3. Thread on blade clamping screw firmly by hand to hold washer in position.

(Screw has right hand threads and must be turned clockwise to tighten.)

4. Lightly depress the blade lock (A) while turning the spindle until the blade stops

rotating.

5. Tighten blade clamping screw (clockwise) firmly with the blade wrench.

6. To remove blade, turn off the tool and remove the battery pack. Engage the

blade lock (Pic E2 (A)) and unscrew the blade clamping screw by turning it

counterclockwise with the blade wrench.

7. Retract the lower guard and lift blade off spindle.

NOTE: Never engage the blade lock while saw is running, or engage in an effort to

stop the tool. Never turn the tool on while the blade lock is engaged. Serious

damage to your saw will result.

Blades

A dull blade will cause slow, inefficient cutting, overload on the saw motor, excessive

splintering, and could increase the possibility of kickback. Recommended blades for

use with your tool are available at extra cost from your local retailer or DEWALT

Service Centre.

For information or assistance regarding blades, please call

Australia 1 800 816 900 New Zealand 09 579 7600.

D

EWALT offer a range of thin kerf circular saw blades specifically designed for

cordless 6 1/2” circular saws.

CAUTION: Do not use abrasive discs or blades for cutting ferrous (steel) materials,

glass or tile.

WARNING: To minimise the risk of eye injury, always use eye protection. Carbide is

a hard but brittle material. Foreign objects in the work piece such as wire or nails

can cause tips to crack or break. Only operate tool when proper saw blade guard is

in place. Mount blade securely in proper rotation before using, and always use a

clean, sharp blade.

It is a good practice to keep extra blades on hand so that sharp blades are available

while the dull ones are being sharpened (See ‘SAWS-SHARPENING’ in the Yellow

Pages). In fact, many lower priced blades can be replaced with new ones at very

little cost over the sharpening price.

Hardened gum on the blade will slow down the cutting. This gum can best be

removed with kerosene, turpentine or oven cleaner.

Cutting Depth Adjustment (Fig. E4 (a) (b) (c) & E5)

1. TURN OFF TOOL AND REMOVE BATTERY PACK.

2. Hold the saw firmly and loosen

(counterclockwise) the depth

adjustment lever (A) and move

shoe (B) up or down, to obtain the

desired depth of cut.

3. Make sure the depth adjustment

lever have been retightened

(clockwise) before operating the

saw.

For the most efficient cutting action, set

the depth adjustment so that one tooth

of the blade will project below the

material to be cut. (Fig. E5) This distance

is from the tip of the tooth (T) to the

bottom of the gullet (G) in front of it. This keeps

blade friction at a minimum, removes sawdust

from the cut, results in cooler,

faster sawing and reduces the

chance of kickback.

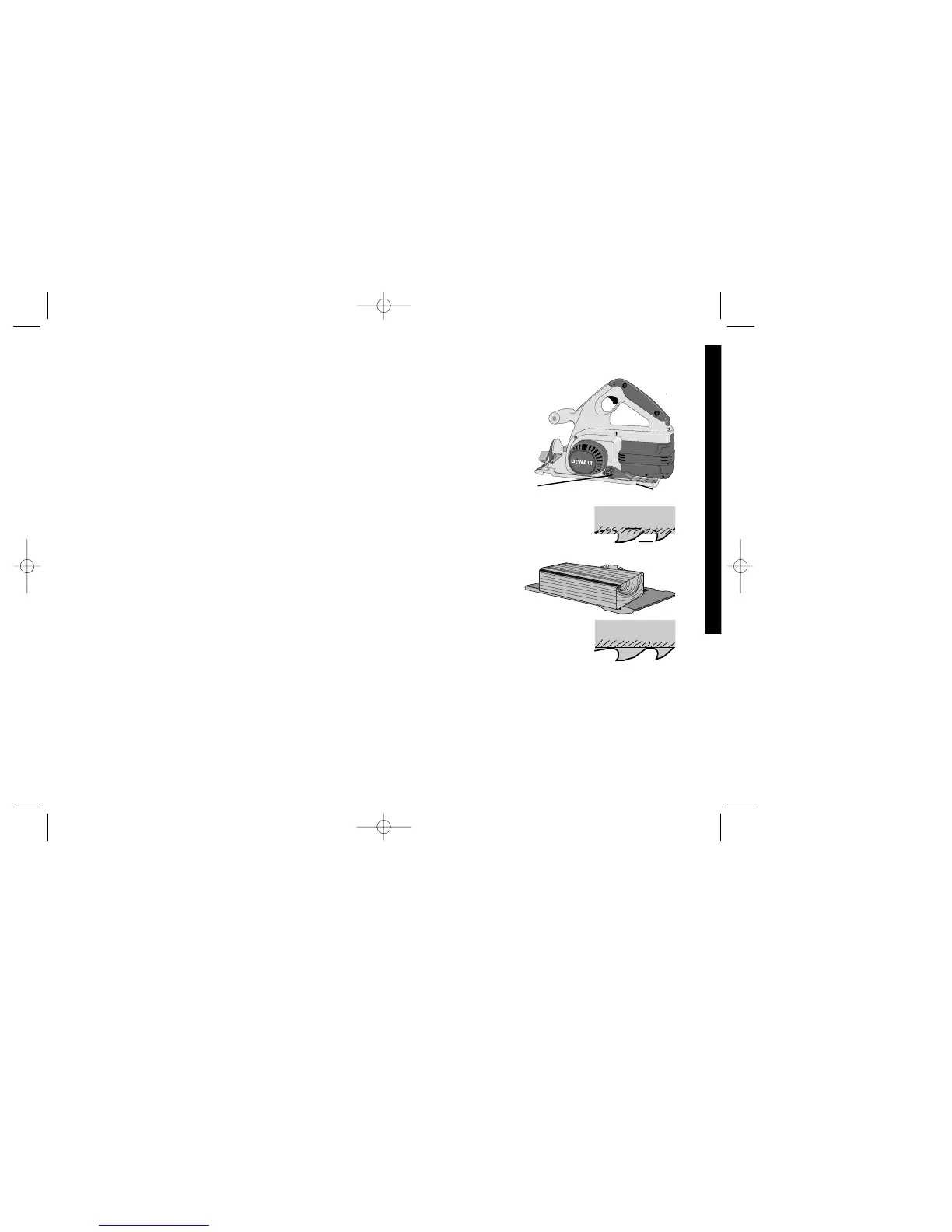

A method for checking for correct

cutting depth is shown in Fig. E6.

Lay a piece of the material along

the side of the blade, as shown,

and observe how much tooth projects beyond

the material.

NOTE: When using a carbide tipped blade,

make an exception to the above procedure and

allow a full tooth to project below the material,

as shown in Figure E7.

Bevel Angle Adjustment (Fig. E8)

TURN OFF THE SAW AND REMOVE THE BATTERY PACK.

The full range of the Bevel Adjustment is from O TO 45 DEGREES. The quadrant is

graduated in increments of 5 degrees.

On the front of the saw is a bevel angle adjustment mechanism consisting of a

calibrated quadrant and a lever or knob. To set the saw for a bevel cut;

E4

E6

A

B

E5

E7

T

G

Loading...

Loading...