9

ENGLISH

Set‑up: Plunge Base (Fig. A, I, J, K)

Motor Quick Release

1. Open the locking lever

4

on thebase.

2. Grasp the top of the motor unit and lift it from thebase.

Inserting the Motor into the Plunge Base

1. Remove the depth adjustment ring from the motor. It is

not used with the plungebase.

2. Open the locking lever

4

on the base to ensure that the

motor properlyseats.

3. Ensure that the plunge lock lever

17

islocked.

4. Align the flat of the motor’s end cap

27

with pillar

28

and insert the motor into the plunge base until itstops.

5. Close the locking lever

4

.

Operation: Fixed and D–Handle Base

Gripping Locations (Fig. A)

Fixed Handle Base: Grip both knob handles

5

whileoperating.

D-Handle Base: Grip D‑Handle

20

and knob handle

5

whileoperating.

The D‑Handle router base has two positions for the knob to

accommodate right or left handuse.

Trigger Lock (Fig. A)

D-Handle Base Only

To lock the trigger, pull the trigger switch

13

completely,

then push the trigger lock button

14

. The router will remain

on after you remove your finger from the trigger. To unlock

the trigger lock button, pull the trigger and release. The lock

button will pop out and the router will turnoff.

4. Connect the short cord

26

from top of D‑Handle to the

motor as shown. Be sure the cord islocked.

5. Place the toggle switch in the ON position. This allows

the trigger switch on the D‑handle to control therouter.

Adjusting the Depth of Cut (Fig. A, C, H)

1. Select and install the desired bit. See the heading Bit

Installation andRemoval.

2. Place the router on its base on theworkpiece.

3. Open the locking lever

4

and turn the depth adjustment

ring

2

until the bit just touches the workpiece. Turning

the ring clockwise raises the cutting head while turning it

counterclockwise lowers the cuttinghead.

4. Move the adjustable scale clockwise so that 0on

the scale is located exactly above the pointer

25

on

thebase.

5. Turn the depth adjustment ring along with the

adjustable scale to the desired depth. Note that each

mark on the adjustable scale represents a depth change

of 1/64" or .015"(0.4mm).

6. Close the locking lever

4

.

Set‑up: Fixed and D–Handle Base

Motor Quick Release (Fig. A)

1. Open the locking lever

4

on thebase.

2. Grasp the base with one hand while depressing the quick

release latches

1

.

3. With the other hand, grasp the top of the motor unit and

lift it from thebase.

Inserting the Motor into the Base

(Fig. A, C, D, H)

1. Open the locking lever

4

on thebase.

2. Thread the depth adjustment ring

2

onto the motor

until the ring is about halfway between the top and

bottom of the motor. Insert the motor into the base

by aligning the groove on the motor

8

with the guide

pins

23

on the base. Slide the motor down until the

depth adjustment ring snaps into the quick release

latches

1

.

NOTE: Guide pin grooves are located on either side of the

motor so that it can be positioned in twoorientations.

3. Close the locking lever when the desired depth is

achieved. For in formation on setting cutting depth, refer

to Adjusting the Depth ofCut.

For D–Handle Base Only (Fig.H)

1. Be sure that the trigger switch

13

is released and

the trigger lock button

14

is in the unlocked and

offposition.

2. Unlock and disconnect the detachable cordset

11

from

themotor.

3. Connect the detachable cordset

11

to bottom of

D‑Handle and lock thecord.

to load the motor, you could damage the motor by

overheating. Reduce the depth of cut and/or slow the

feed rate to prevent tooldamage.

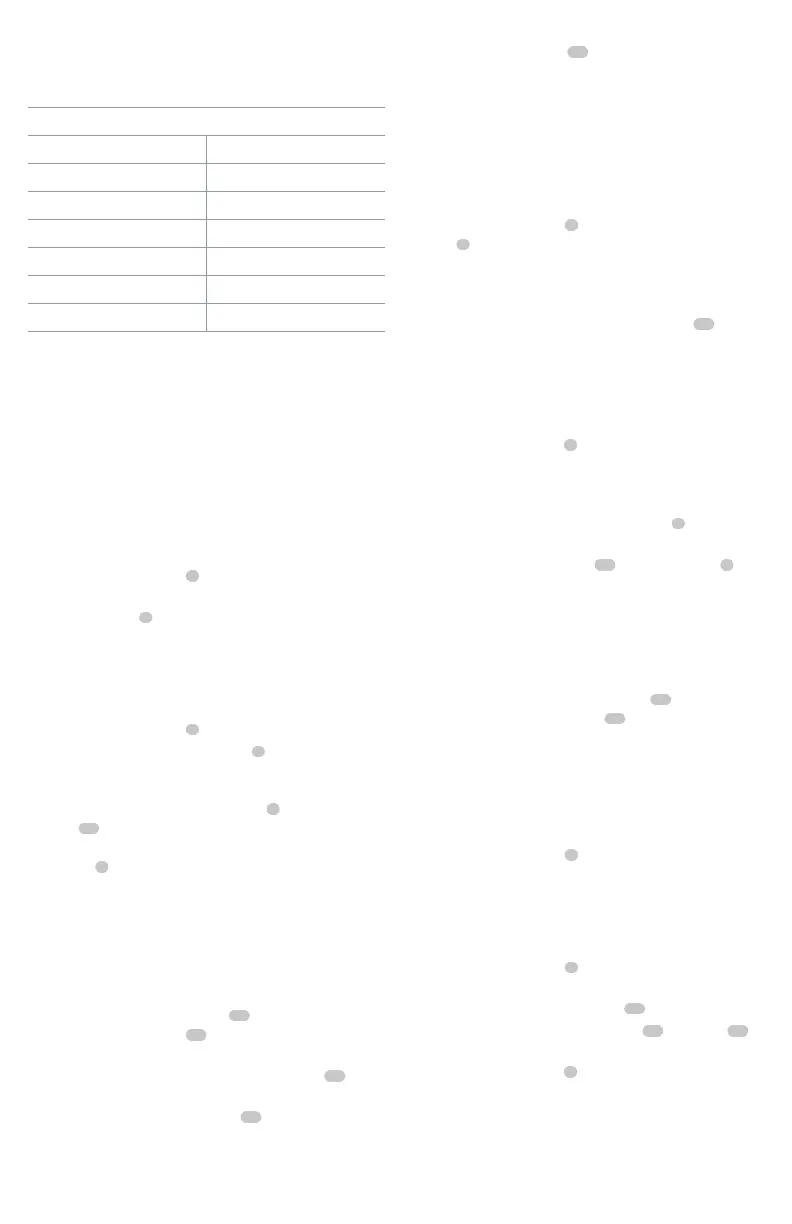

SPEED SELECTION CHART

DIAL SETTING APPROX. RPM

1 8000

2 12000

3 14000

4 18000

5 21000

6 24000

The speeds in this chart are approximate and are for

reference only. Your router may not produce the exact speed

listed for the dialsetting.

WARNING: Always follow the bit manufacturer’s speed

recommendations as some bit designs require specific

speeds for safety orperformance.

If you are unsure of the proper speed or are experiencing any

type of problem, contact the bitmanufacturer.

Loading...

Loading...