5

ENGLISH

CAUTION:

• Never depress the spindle lock button while the blade is under power orcoasting.

• Do not cut ferrous metal (containing iron or steel) or masonry or fiber cement product

with this mitersaw.

Removing the Blade

1. Unplug thesaw.

2. Raise the arm to the upper position and raise the lower guard

4

as far aspossible.

3. Loosen, but do not remove guard bracket screw

39

until the bracket can be raised far

enough to access the blade screw

34

. Lower guard will remain raised due to the position of

the guard bracketscrew.

4. Depress the spindle lock button

24

while carefully rotating the saw blade by hand until the

lockengages.

5. Keeping the button depressed, use the other hand and the 6mm hex wrench

16

provided

to loosen the blade screw. (Turn clockwise, left-hand threads.)

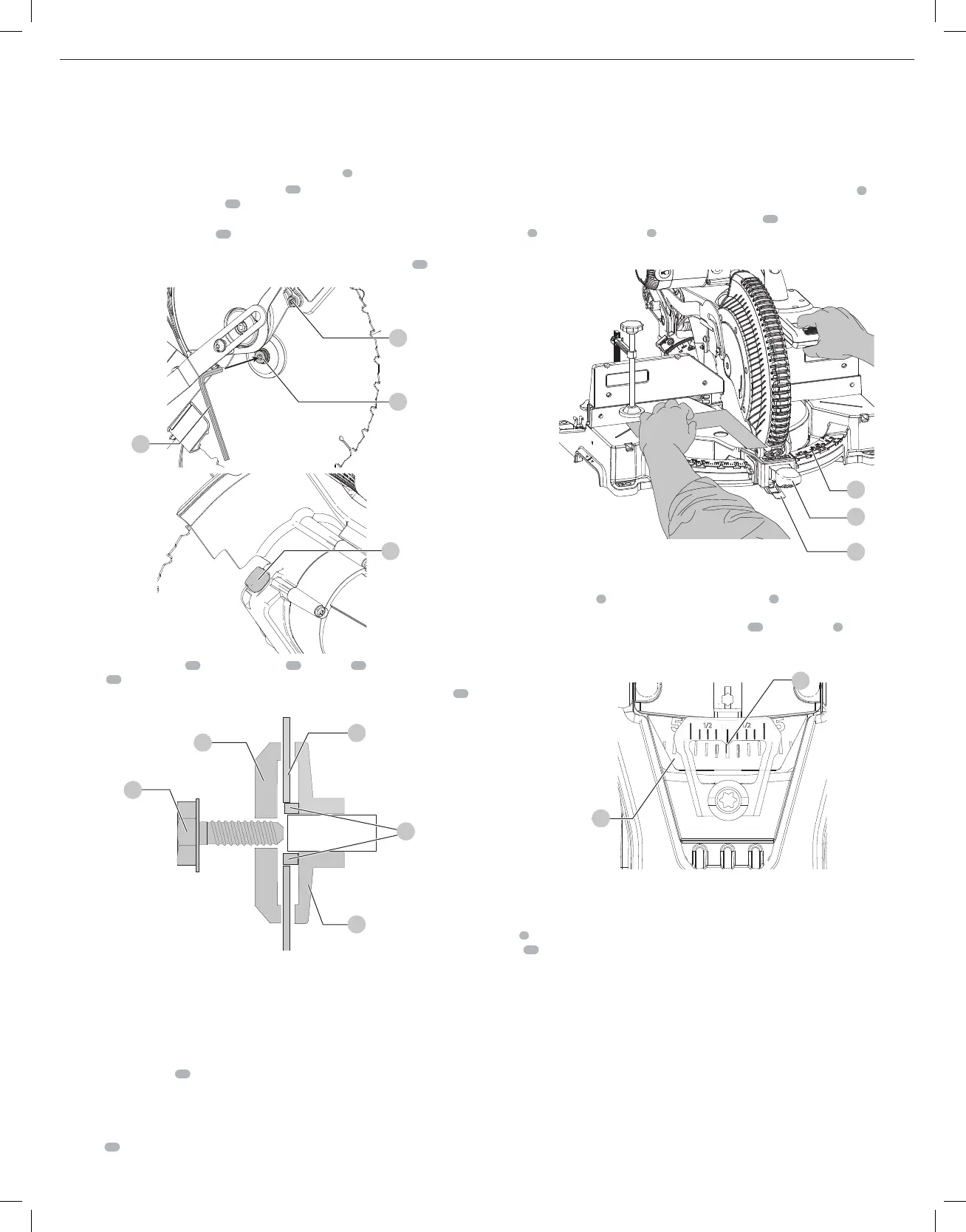

Fig. C

16

23

39

Fig. D

24

6. Remove the blade screw

34

, outer blade clamp

25

, and blade

26

. The inner blade

clamp

27

, and if used, the 1" (25.4 mm) blade adapter, may be left on thespindle.

NOTE: For blades with a blade hole of 5/8" (15.88 mm), the 1" (25.4 mm) blade adapter

40

is notused.

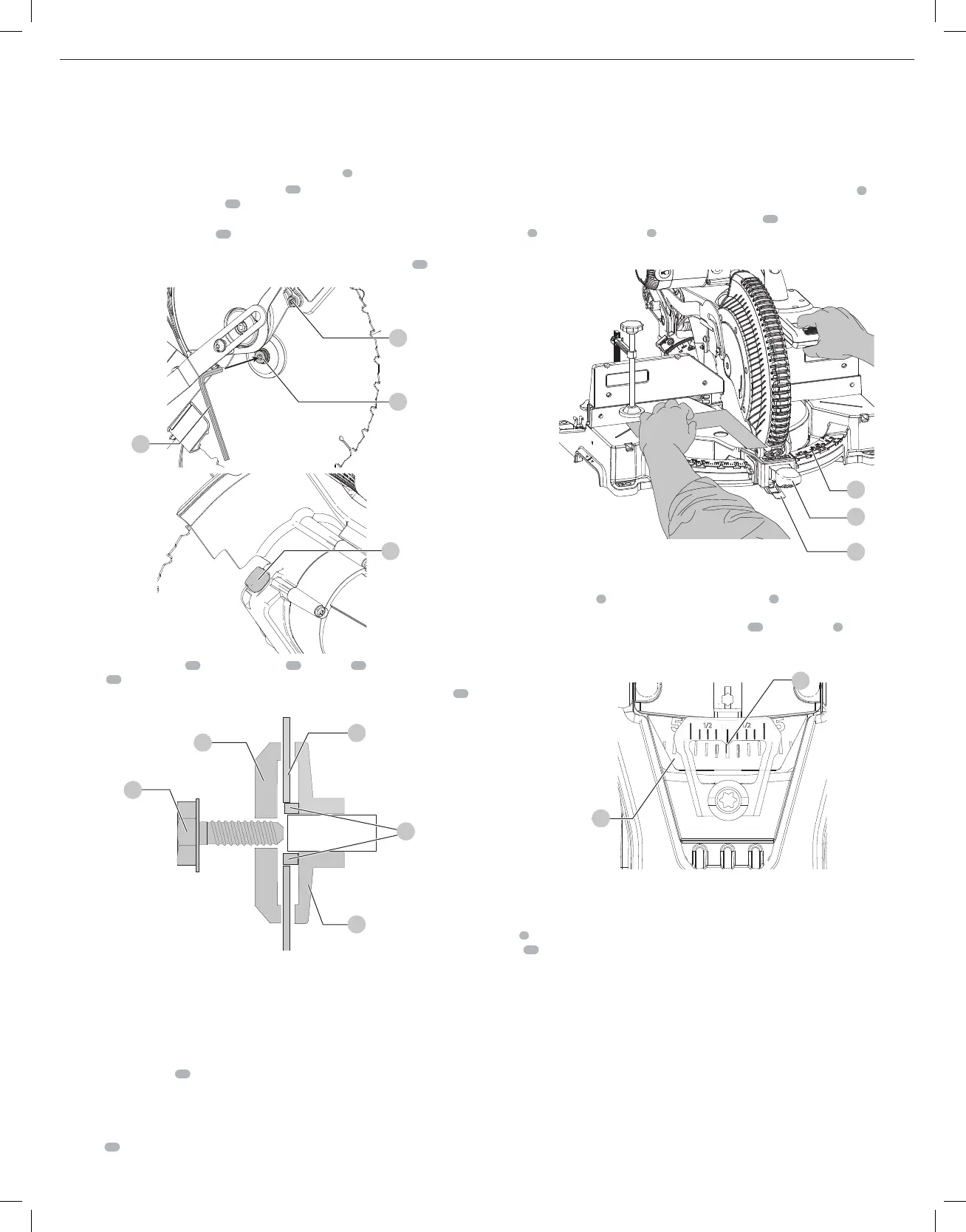

Fig. E

34

25

26

27

40

Installing a Blade

1. Unplug thesaw.

2. With the arm raised, the lower guard held open and the guard bracket, place the blade on

the spindle, onto the blade adapter [if using a blade with a 1" (25.4 mm) diameter blade hole]

and against the inner blade clamp with the teeth at the bottom of the blade pointing toward

the back of thesaw.

3. Assemble the outer blade clamp onto thespindle.

4. Install the blade screw

34

and, engaging the spindle lock, tighten the screw firmly with the

6mm hex wrench provided. (Turn counterclockwise, left-hand threads.)

NOTE: When using blades with a 5/8" (15.88 mm) diameter blade hole, the blade adapter will

not be used and should be stored in a safe place for futureuse.

5. Return the guard bracket to its original position and firmly tighten the guard bracket

screw

39

to hold bracket inplace.

WARNING:

• The guard bracket must be returned to its original position and the screw

tightened before activating thesaw.

• Failure to do so may allow the guard to contact the spinning saw blade resulting

in damage to the saw and severe personalinjury.

Miter Scale Adjustment (Fig. A, F)

Place a square against the saw’s fence and blade. (Do not touch the tips of the blade teeth with

the square. To do so will cause an inaccurate measurement.) Unlock miter lock lever

5

and swing

the miter arm until the miter detent locks it at the 0˚ miter position. Do not lock miter lock lever.

If the saw blade is not exactly perpendicular to the base fence

18

, loosen the three miter scale

screws

8

that hold the miter scale

7

to the base and move the scale/miter arm assembly left or

right until the blade is perpendicular to the fence, as measured with the square. Retighten the

three screws. Pay no attention to the reading of the miter pointer at thispoint.

Fig. F

5

7

6

Miter Pointer Adjustment (Fig. F, G)

Unlock miter lock lever

5

and squeeze the miter detent trigger

6

to move the miter arm to

the zero position. Unlock the miter lock lever to allow the miter detent to snap into place as

you rotate the miter arm toward zero. Observe the pointer

28

and miter scale

7

through the

viewing opening shown in FigureG. If the pointer does not indicate exactly zero, loosen the

pointer screw, adjust the pointer to 0˚ andretighten.

Fig. G

7

28

Bevel Square to Table (Fig. A, H)

To align the blade square to the rotary table, lock the arm in the down position. Place a square

against the blade taking care to not have the square on top of a tooth. Loosen the bevel lock

lever

5

and ensure the arm is firmly against the 0° bevel stop. Move the 0° bevel stop adjusting

screw

32

as necessary so that the blade is at 0° bevel to the table. Ensure the bevel override

levers are pushed inward to obtain an accurateadjustment.

Loading...

Loading...