T1000

Model T1000 Cat. No. DDF211001P

6

caused local hardening of the steel.

15. Do not fasten through a predrilled hole unless proper guidance

is provided.

16. If you decide not to make a fastening after the tool has been

loaded, you must always remove the powder load first followed

by the fastener.

17. Never attempt to override the safety features of this tool.

HANDLING THE TOOL AND POWDER LOADS

1. Never leave a loaded tool unattended. Once the tool is loaded,

make the fastening immediately or unload the tool.

2. Always unload the tool before work breaks, changing parts,

cleaning or servicing, and when storing.

3. To prevent accidental discharge of loads, never carry the powder

loads in the same container as the fasteners or other hard objects.

4. Always store the powder loads in the containers provided or

in an enclosure provided for them. Never intermix the various

power levels. Keep them segregated in clearly identified

containers.

5. Powder loads should never be used in firearms. They are

normally more powerful that the cartridges supplied with the

firearms.

6. Powder actuated tools and powder loads should always be

stored under lock and key. Tools must be unloaded when not in use.

TOOL MALFUNCTION

1. In the event that a load fails to discharge after the trigger

is pulled, the tool must be kept depressed against the work

surface for a minimum of 30 (thirty) seconds in case of a

delayed load discharge. Then carefully remove the entire load

strip. and dispose of it in a can of water or other nonflammable

liquid. Never attempt to force or pry a load out of a tool

chamber.

2. Never discard unfired powder loads into a trash container.

3. Do not attempt to unload or disassemble a jammed, stuck or

broken tool as improper handling may cause it to discharge

and strike operator and/or bystander. A jammed tool must be

pointed in a safe direction at all times. Tag the tool and lock

it up. Call your D

EWALT Fasteners representative for proper

assistance.

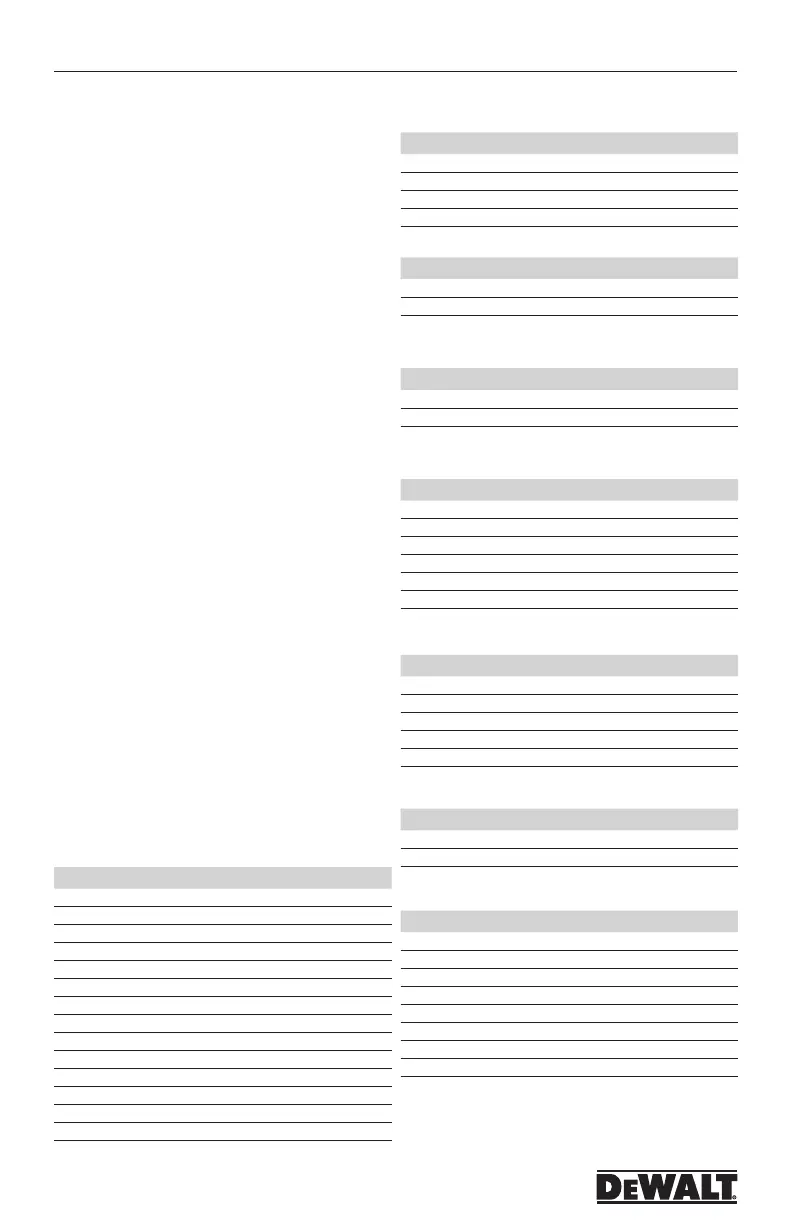

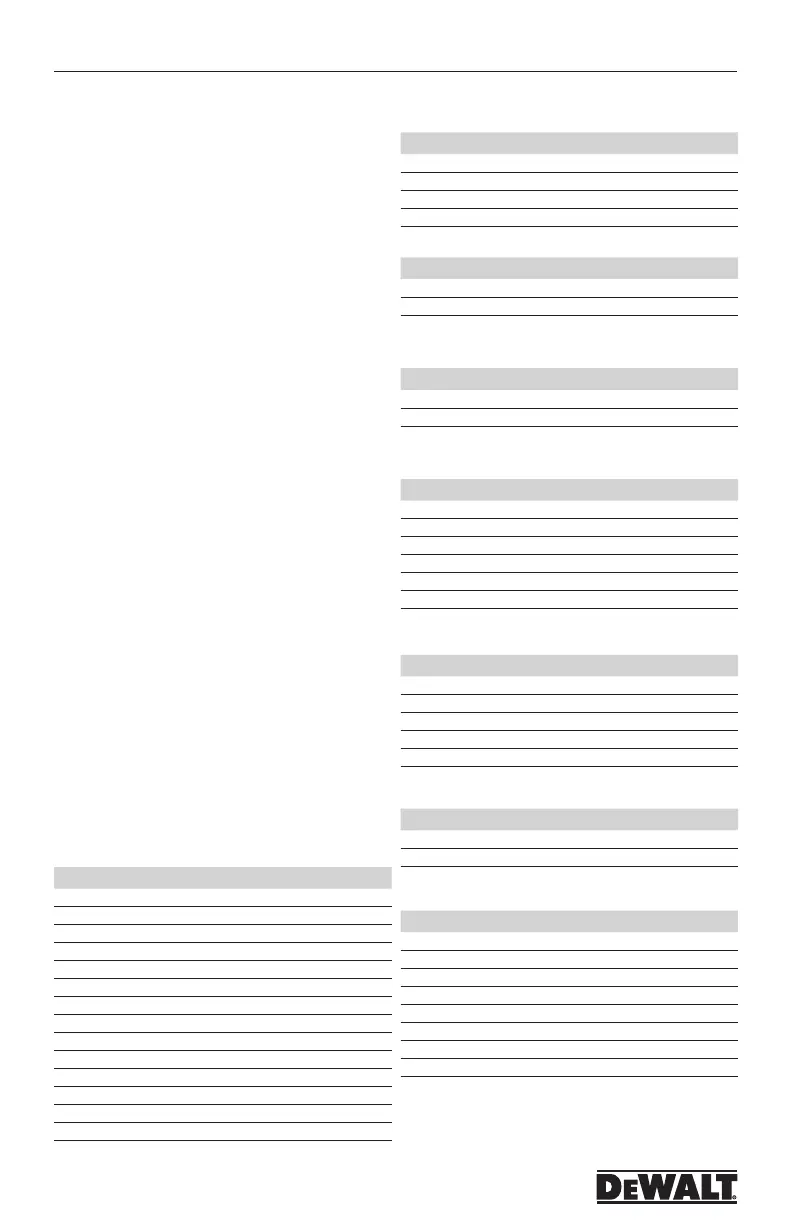

FasTener selecTion Guide

300 HEAD DIAMETER DRIVE PINS

CAT

NO.

ShANK

LENGTh

STD.

BOx

STD.

CTN

hEAD

DIA.

ShANK

DIA.

WT./

100

DDF3011000 1/2” K 100 5000 .300 .143 .5

DDF3011050 5/8” K 100 5000 .300 .143 .5

DDF3001100 3/4” 100 5000 .300 .143 .5

DDF3001150 1” 100 5000 .300 .143 .6

DDF3001200 1-1/8” 100 1000 .300 .143 .7

DDF3001250 1-1/4” 100 1000 .300 .143 .8

DDF3001300 1-1/2” 100 1000 .300 .143 .9

DDF3001350 1-3/4” 100 1000 .300 .143 1.1

DDF3001400 2” 100 1000 .300 .143 1.2

DDF3001450 2-1/4” 100 1000 .300 .143 1.2

DDF3001500 2-3/8” 100 1000 .300 .143 1.3

DDF3001550 2-1/2” 100 1000 .300 .143 1.4

DDF3001600 2-3/4” 100 1000 .300 .143 1.6

DDF3001650 3” 100 1000 .300 .143 1.9

.300 HEAD DIAMETER DRIVE PINS WITH TOP HAT

CAT

NO.

ShANK

LENGTh

STD.

BOx

STD.

CTN

hEAD

DIA.

ShANK

DIA.

WT./

100

DDF3031000 1/2” K 100 5000 .300 .143 .5

DDF3031050 5/8” K 100 5000 .300 .143 .5

DDF3031100 3/4” 100 5000 .300 .143 .5

DDF3031150 1” 100 5000 .300 .143 .6

.300 HEAD DIAMETER STEP SHANK PINS

CAT

NO.

ShANK

LENGTh

STD.

BOx

STD.

CTN

hEAD

DIA.

ShANK

DIA.

WT./

100

DDF3041000 3/4” Step Shank 100 1000 .300 .143/130 .5

DDF3041050 1” Step Shank 100 1000 .300 .143/130 .6

.300 HEAD DIAMETER DRIVE PINS WITH 3/4” WASHER

CAT

NO.

ShANK

LENGTh

STD.

BOx

STD.

CTN

hEAD

DIA.

ShANK

DIA.

WT./

100

DDF3051100 3/4” 100 1000 .300 .143 1.6

DDF3051200 2-1/2” 100 1000 .300 .143 2.5

. 300 HEAD DIAMETER DRIVE PINS WITH 7/8” WASHER

CAT

NO.

ShANK

LENGTh

STD.

BOx

STD.

CTN

hEAD

DIA.

ShANK

DIA.

WT./

100

DDF3061150 1” 100 1000 .300 .143 1.9

DDF3061250 1-1/4” 100 1000 .300 .143 2.0

DDF3061300 1-1/2” 100 1000 .300 .143 2.1

DDF3061400 2” 100 1000 .300 .143 2.4

DDF3061550 2-1/2” 100 1000 .300 .143 2.7

DDF3061650 3” 100 1000 .300 .143 3.0

.300 HEAD DIAMETER DRIVE PINS WITH 1” WASHER

CAT

NO.

ShANK

LENGTh

STD.

BOx

STD.

CTN

hEAD

DIA.

ShANK

DIA.

WT./

100

DDF3071000 1-1/4” 100 1000 .300 .143 2.2

DDF3071050 1-1/2” 100 1000 .300 .143 2.3

DDF3071250 2” 100 1000 .300 .143 2.6

DDF3071150 2-1/2” 100 1000 .300 .143 2.9

DDF3071200 3” 100 1000 .300 .143 3.2

.300 HEAD DIA. DRIVE PINS W. 1-7/16” INSULATION WASHER

CAT

NO.

ShANK

LENGTh

STD.

BOx

STD.

CTN

hEAD

DIA.

ShANK

DIA.

WT./

100

DDF3081000 1-1/2” 100 1000 .300 .143 2.1

DDF3081050 2-1/2” 50 500 .300 .143 2.7

1/4”-20 THREADED STUDS

CAT

NO.

ThREAD

LENGTh

ShANK

LENGTh

STD.

BOx

STD.

CTN

hEAD

DIA.

ShANK

DIA.

WT./

100

DDF3811020 1/2” 1/2”K 100 5000 1/4” .143 .8

DDF3811000 3/4” 1/2”K 100 1000 1/4” .143 1.1

DDF3811050 3/4” 3/4” 100 1000 1/4” .143 1.2

DDF3811100 1/2” 1” 100 1000 1/4” .143 1.2

DDF3811150 3/4” 1” 100 1000 1/4” .143 1.4

DDF3811180 1/2” 1-1/4” 100 1000 1/4” .143 1.4

DDF3811200 3/4” 1-1/4” 100 1000 1/4” .143 1.5

DDF3811250 1-1/4” 1-1/4” 100 1000 1/4” .143 1.7

POW2272_dw_t1000_booklet.indd 6 3/10/14 12:45 PM

Loading...

Loading...