Model T1000 Cat. No. DDF211001P

T1000

9

TRIM ALONG DOTTED LINE, PLACE IN ENVELOPE, ADDRESS AS SHOWN AND AFFIX POSTAGE

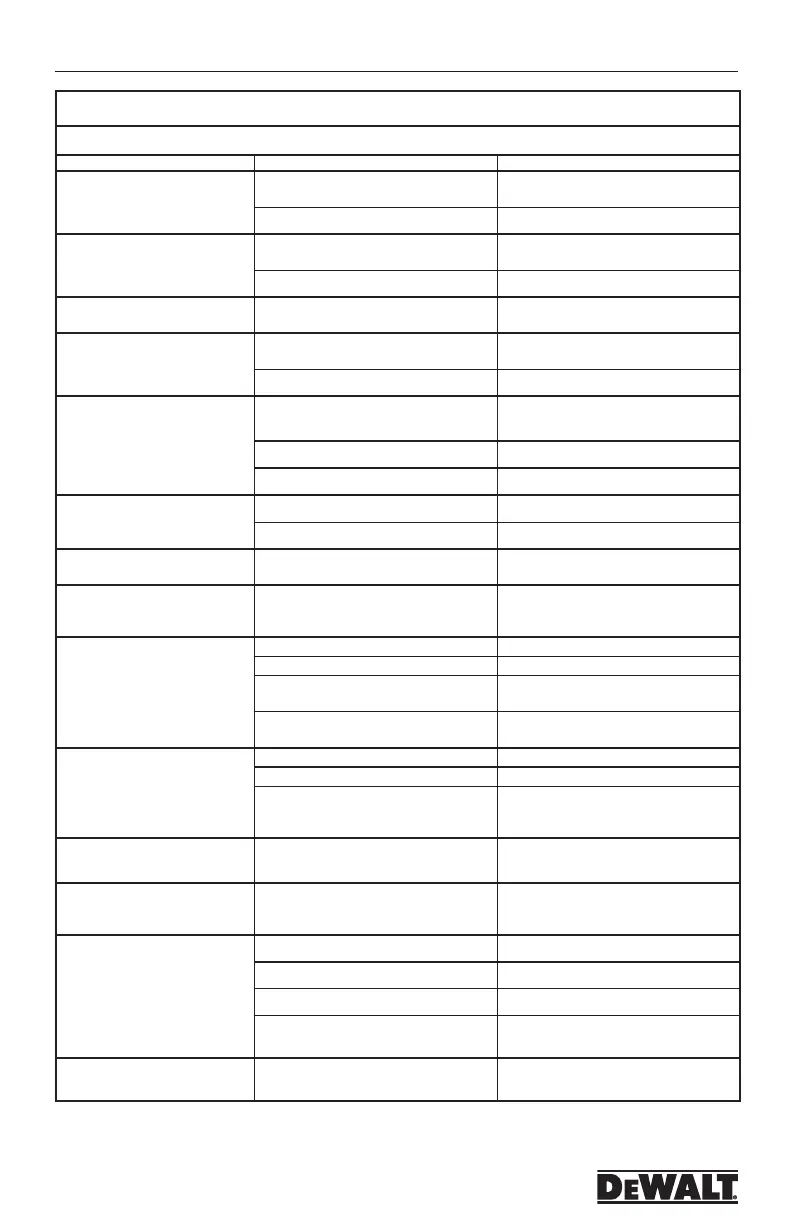

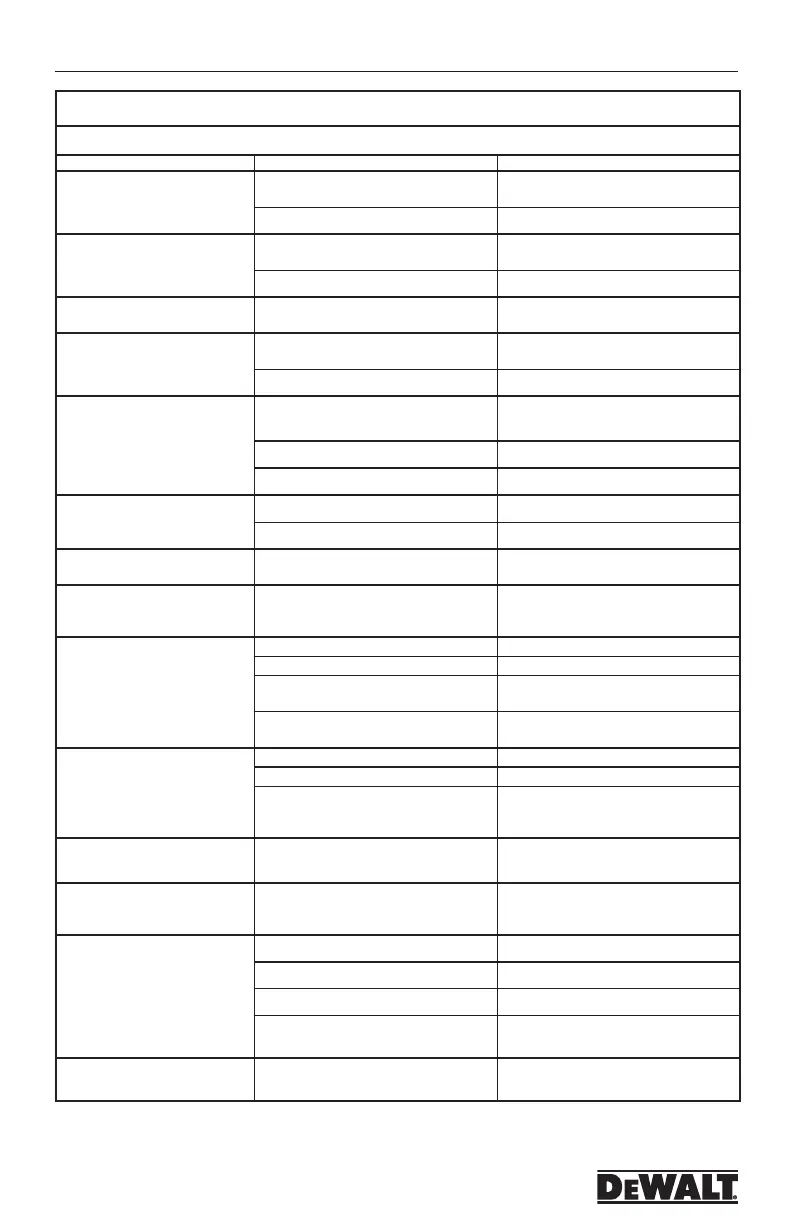

Troubleshooting

ALWAYS CHECK INSTRUCTION MANUAL FOR PROPER ASSEMBLY OF PARTS

PROBLEM POSSIBLE CAUSE SOLUTION

Fastener Overdriving Power level too high / Pin too short Use a lower powder load level number or a

longer pin

Soft base material Check base material suitability section

Tool does not fire Tool not depressed completely See “Tool does not depress completely”

section below

Firing pin damaged Replace damaged part(s)

Tool does not depress completely Damaged firing pin parts, ejector, etc. Parts

assembled improperly

Check the parts for damage or improper

assembly

Power reduction or inconsistent

fastener penetra tion

Barrel is not pulled fully forward when cycling

tool.

Barrel must be pulled out completely to properly

reset the piston

Worn or damaged piston Replace piston or piston ring

Powder load will not eject after firing

tool

Barrel is not pulled forward completely when

tool is cycled

Firmly snap the tool open.

If necessary dismantle and clean

Bent Piston or damaged piston ring Remove and replace piston or piston ring

Build-up of dirt in breech Clean breech area

Load strip cannot be

inserted into tool

Improper loading Insert strip from the bottom of the tool handle

Wrong caliber strip Use proper strip

Load strip will not advance Worn advance lever guide Replace advance lever guide. This should be

performed by qualified individuals

Load will not fire when

trigger is pulled

Tool is not fully depressed Follow safety procedure for misfired load then

attempt to fully depress tool before pulling

trigger

Load will not fire when tool is fully

depressed and trigger is pulled

Load is already fired Cycle tool

Load misfire Follow safety procedure

Broken firing pin Replace firing pin nut. This should be performed

by qualified individuals

Broken or missing Replace firing pin nut. This firing pin nut

should be

Tool cannot be opened

or cycled

Lack of proper cleaning Clean tool thoroughly

Damaged or bent piston Remove and replace piston

Broken or damaged parts Tag tool with warning “Defective - Do Not Use”

place in locked container and contact your

D

EWALT Authorized representative for service

Piston stuck in the forward position Piston has been overdriven and is jammed

against piston reset pin

Tap the piston against a hard surface

Chipped or damaged piston Tool not held on work surface squarely.

This allows the piston to slip off the head of the

pin and cause damage to the piston

Machine piston as shown on page ?. Piston

regrinding may be performed only by

qualified individuals

Piston guide will not open easily Bent shear clip Remove and replace shear clip

Excessive build-up of dirt Disassemble and clean tool

Piston stop is damaged Replace piston stop

Foreign material jammed between the piston

guide and steel liner assembly

Disassemble and remove foreign particles

Piston guide opens too easily Annular ball spring or steel annular ball have

worn

Remove and replace with a new spring and/

or ball

POW2272_dw_t1000_booklet.indd 9 3/10/14 12:45 PM

Loading...

Loading...