12

PM-000005 - Trencher Operators Manual - December 2012

SPROCKET REPLACEMENT

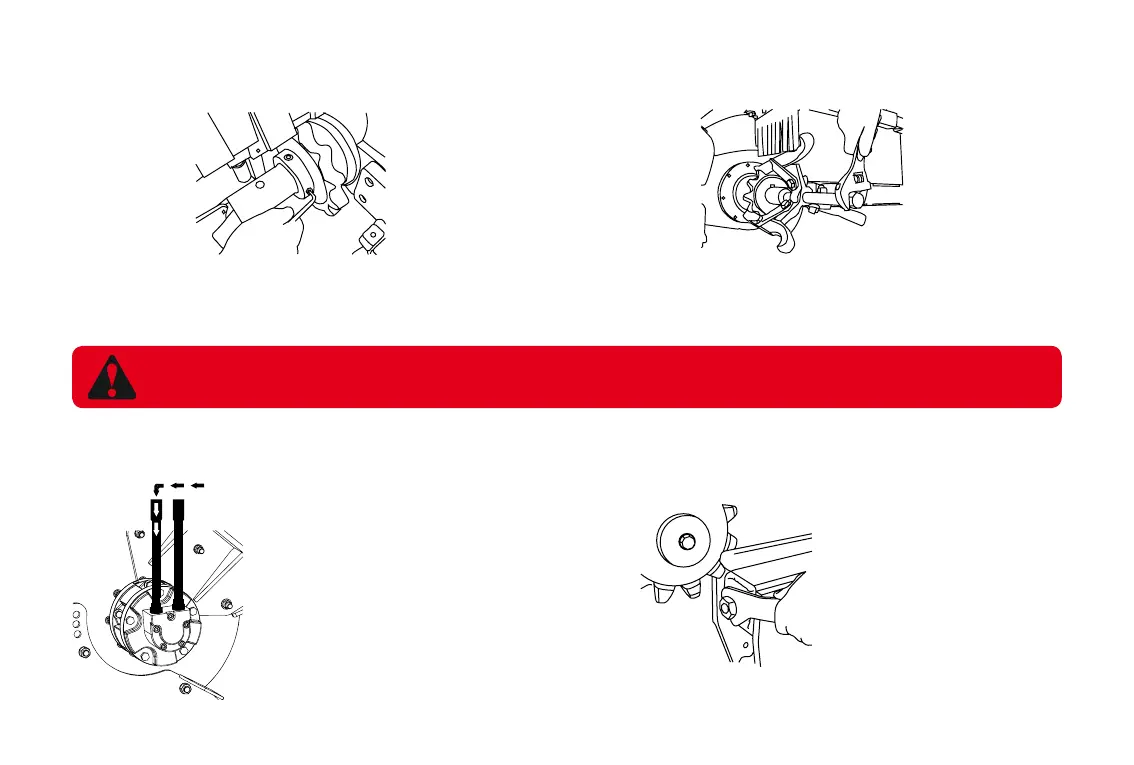

Firstly remove ½” bolt holding the auger, then remove auger.

Using a 3/16” Allen key loosen the 2 grub screws in the

retaining collar and slide collar off the shaft. (shown in Fig 1).

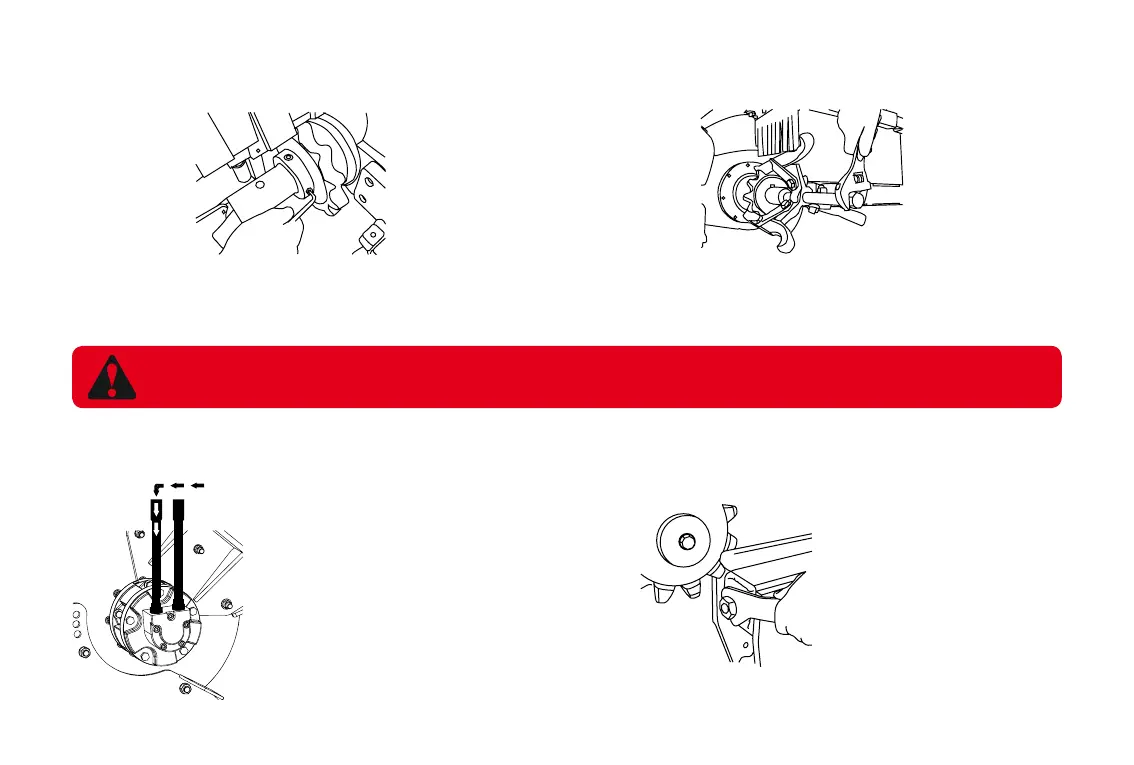

Slide the sprocket off the shaft and replace with new sprocket. It is

recommended Anti-seize be applied to shaft before replacement of

sprocket (Shown in Fig 2)

Fig 1

Fig 2

5 mainTenance

BOOM ADJUSTMENT

iMPORTANT: ShuT dOwN TReNcheR & MAchiNe beFORe ANy AdjuSTMeNTS ARe MAde

1. Use spanner supplied to

wind adjuster nut clockwise

for loosening, anti-clockwise

for tightening

a

b

suPPly from machine

1. The Trencher chain must rotate

in an anti-clockwise direction (when

viewed from the Motor side of the

Trencher). The Supply Line from the

Parent machine must be connected

to the ‘A’ port on the Trencher Motor

HYDRAULIC HOSE CONNECTION

NOTE: IF THE SPROCKET CANNOT BE REMOVED BY TAPPING WITH A HAMMER THEN A PULLER MAY

HAVE TO BE USED.

Loading...

Loading...