101

Cylinders

Start the engine and run at low idling speed for 10min.

Keep the engine running at low idling speed, extend and retract all cylinders for 4~5 times, but

take caution not to telescope any cylinder to the end.

Run the engine at high speed, extend and retract all cylinders for 4~5 times, but take caution not

to telescope any cylinder to the end.

Restore the engine to low idling speed, extend and retract all cylinders for 4~5 times, and always

telescope to the end.

Replace bucket teeth (as necessary)

Replace the bucket teeth when the tooth sleeves

are worn. Do not wait for the bucket to be

damaged before replacement.

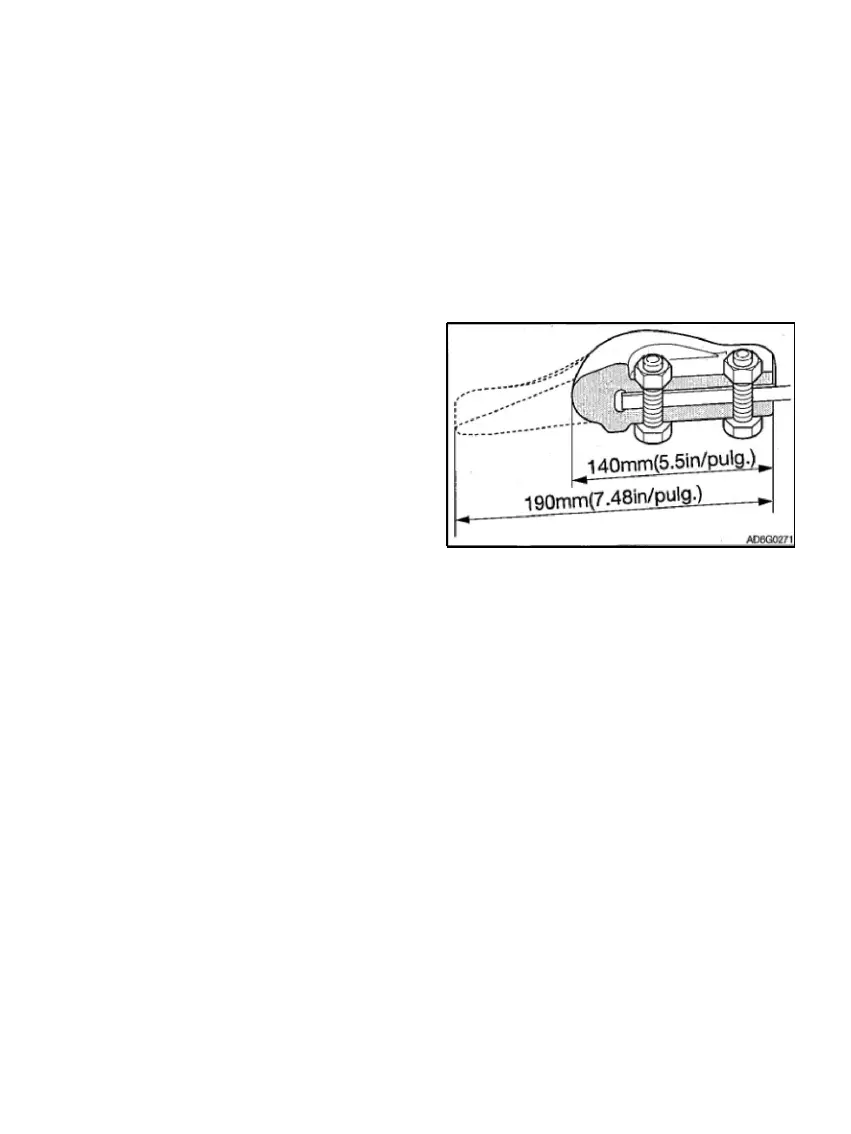

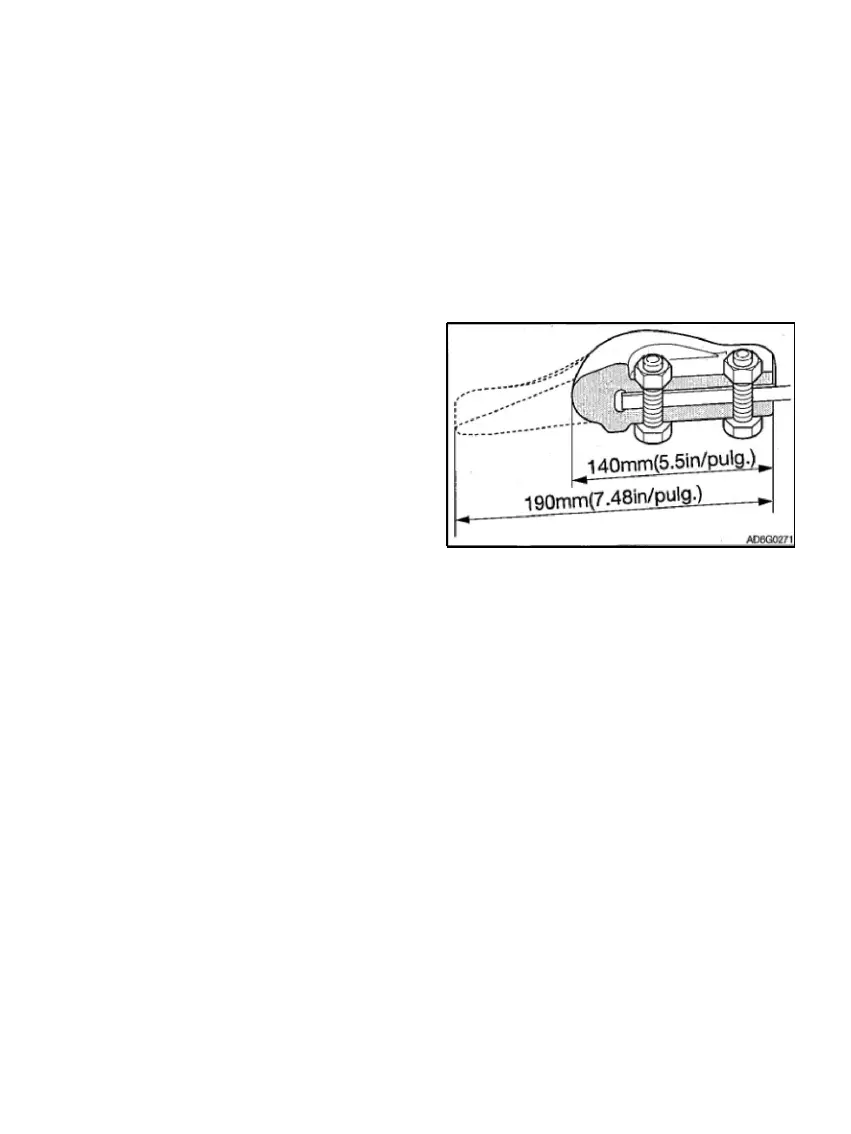

If the bucket teeth are worn to 140mm, replace.

Warning: Before maintenance or repairs beneath

the machine, lower all movable working devices

onto the ground or lowest position.

During the repairs and replacements of bucket

teeth or side teeth, to prevent the accidental movement of machine, securely fix the working

device.

During the use of hammer, the pins and the metal fragments may fly out. It may cause serious

personal harm.

While hammering hard metal parts such as tooth pins, bucket teeth, side teeth, and bearings,

please wear protective articles including goggles and gloves.

While hammering tooth pins and bucket teeth, ensure there is no person in surrounding area.

During operations, non-authorized personnel are prohibited to access the working zone.

Loading...

Loading...