102

Disassembling

Clean the bucket and park the machine on a level, firm, and

safe ground.

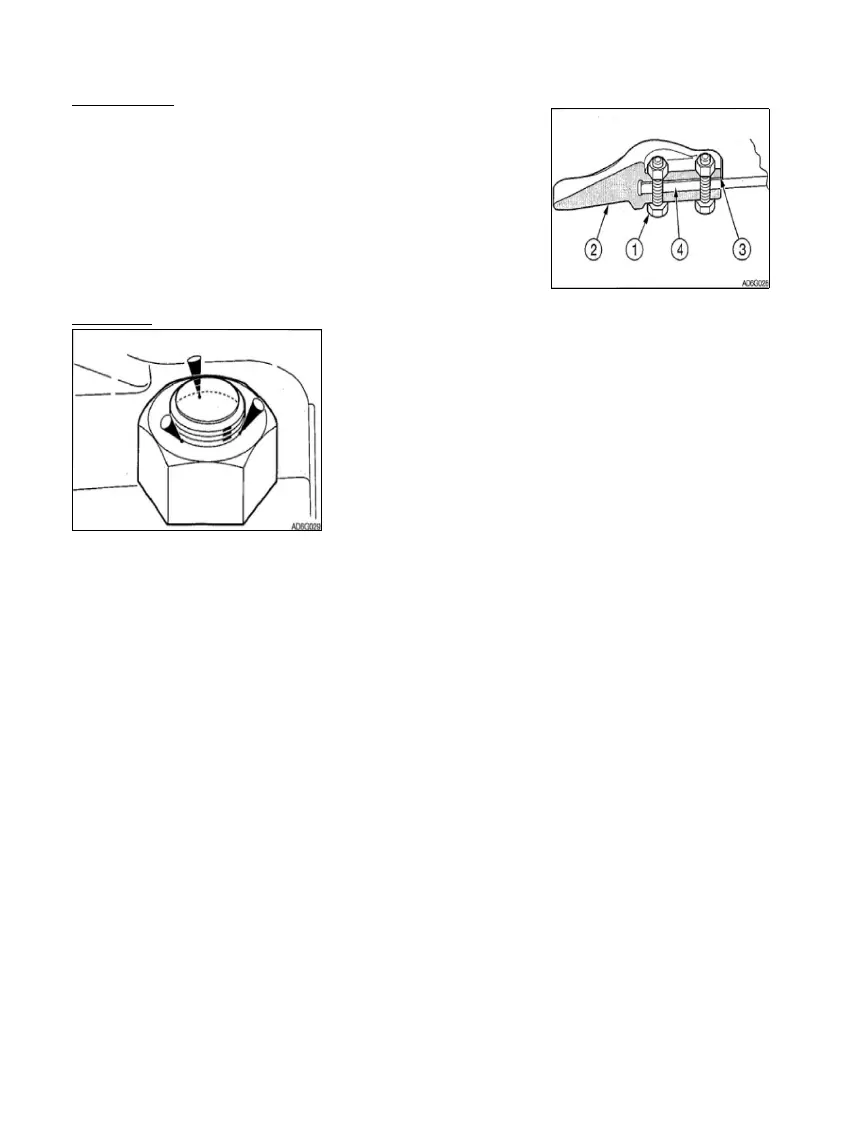

Place level the bottom face of bucket and cushion it with

cushion block to ease the disassembling of bolts (1).

Withdraw the starter key and check bucket for steady

placement.

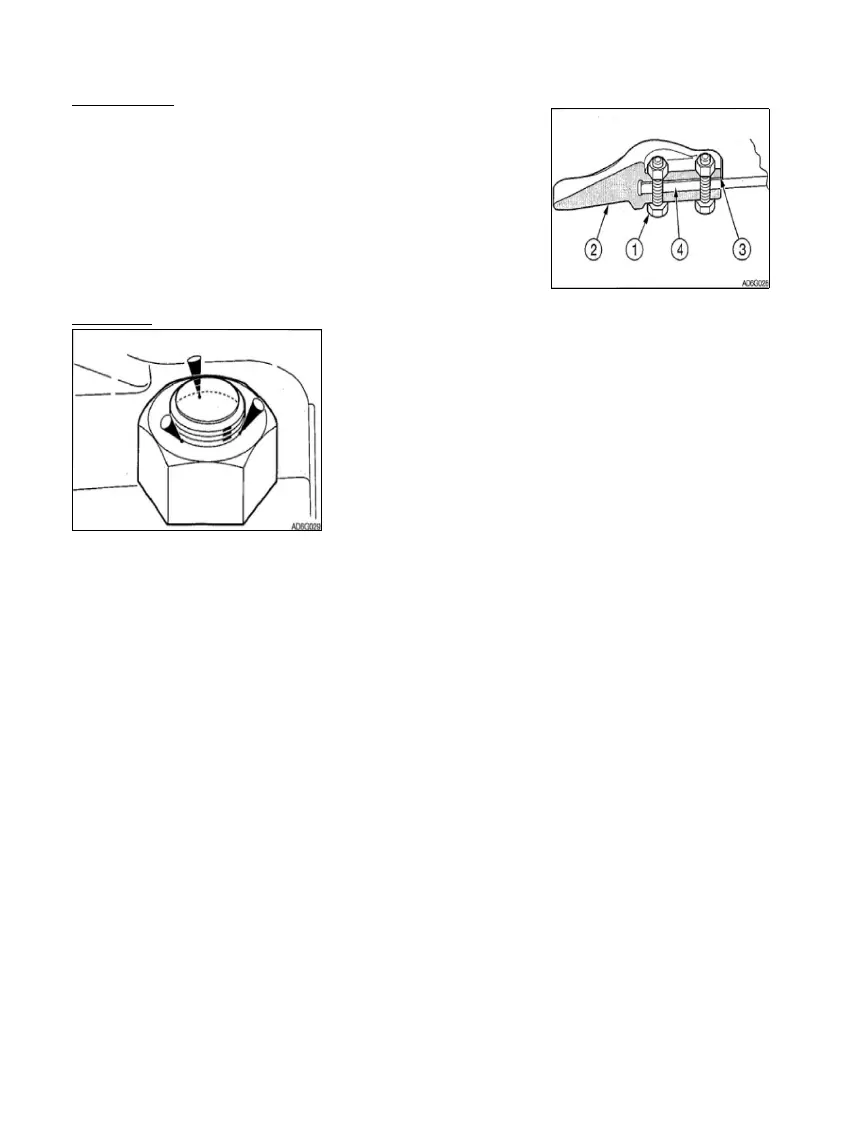

Disassemble the bolts (1).

Replace bucket teeth (2) and shims (3).

Installation

Clean the area for installation of bucket tooth. If there is any

soil or mud in this area, the bucket tooth and tooth sleeve

probably can’t be inserted completely.

Place the bucket tooth into the bucket.

If the bucket tooth is insecure, please insert a shim to

reduce the gap.

Insert the bolt from outer side of bucket and tighten by nut.

Tightening torque: 102 N.m.

Rivet the bolt by a press or perform three-point welding at

the threaded portion (Nut end).

Replacement of Bucket

Warning: Before maintenance or repairs beneath the machine, lower all working devices onto the

ground or lowest position.

If the maintenance requires the running of engine, assign two operators for teamwork and keep

contact with each other.

One operator must sit in the driver seat to get ready to stop the engine immediately when

necessary. This operator must pay special attention not to touch any joystick or pedal, unless it’s

absolutely necessary.

The other operator for the maintenance must keep the body and clothing away from motion

parts of machine.

During the use of hammer, the pins and the metal fragments may fly out. It may cause serious

personal harm.

While hammering hard metal parts such as tooth pins, bucket teeth, side teeth, and bearings,

please wear protective articles including goggles and gloves.

While hammering tooth pins and bucket teeth, ensure there is no person in surrounding area.

While aligning pinholes, always check by visual observation. Do not insert your finger into

pinholes, otherwise your finger may be lost.

Loading...

Loading...