81

Critical Safety Parts

To operate the machine safely, please fulfill the periodical checking and maintenances. The

following critical safety parts shall be replaced periodically to improve safety. These parts can

cause serious injuries or fire accident if they are damaged.

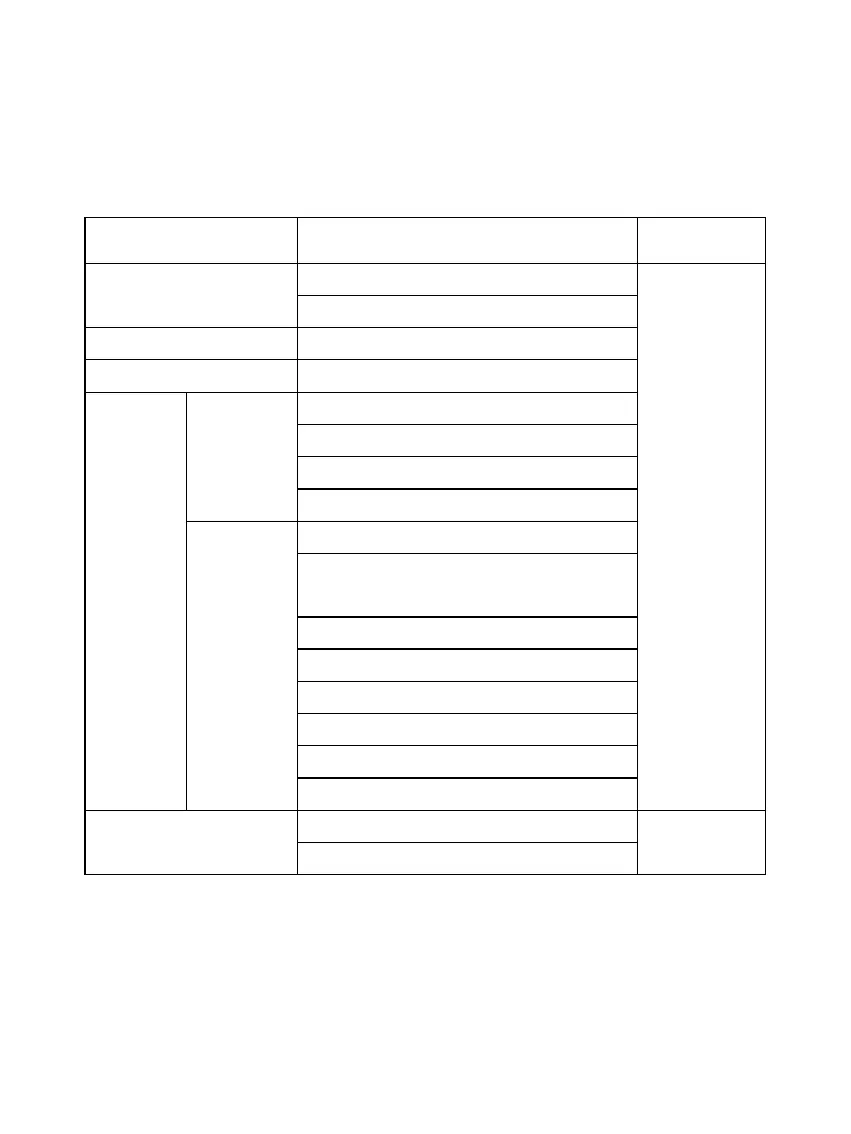

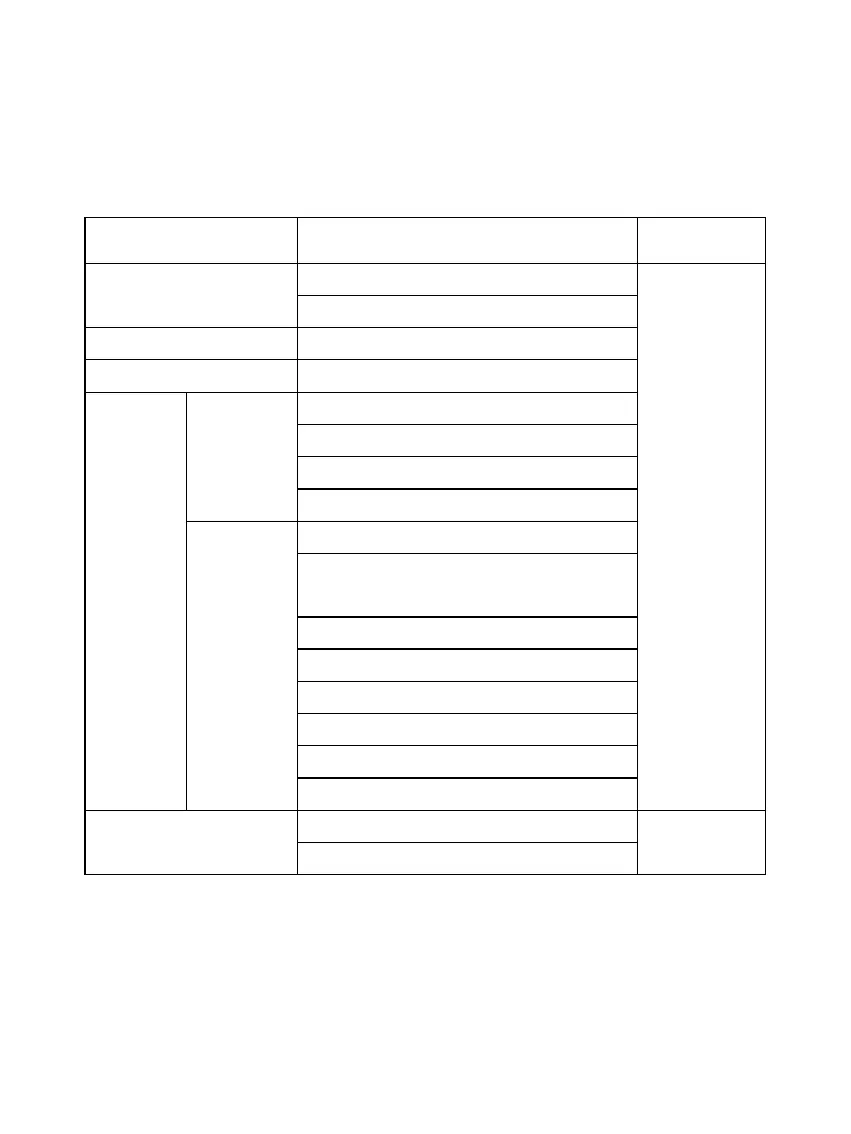

List of Critical Safety Parts

Periodically replaced critical safety part

Packing on fuel tank cover

Hydraulic pipe (Pump outlet)

Hydraulic pipe (Pump oil suction port)

Hydraulic pipe (Slewing motor)

Hydraulic pipe (Traveling motor)

Hydraulic pipe (Boom cylinder pipeline)

Hydraulic pipe (Bucket arm cylinder

Hydraulic pipe (Bucket cylinder pipeline)

Hydraulic pipe (Swing cylinder)

Hydraulic pipe (Bulldozing blade cylinder)

Hydraulic pipe (Span cylinder)

Hydraulic pipe (Pilot valve)

Hydraulic pipe (Auxiliary pipeline)

The materials of the above-mentioned critical safety parts will deteriorate along with time to

cause wear or deteriorated performance. It’s difficult to determine the deterioration extent

during periodical checking. Therefore, such parts shall be replaced with new ones to guarantee

stable performance, even if such parts are still working well. Please be noted that, regardless of

the replacement schedule, any part with wear symptom must be replaced immediately. Upon

Loading...

Loading...