90

Checking

Open left side gate of machine.

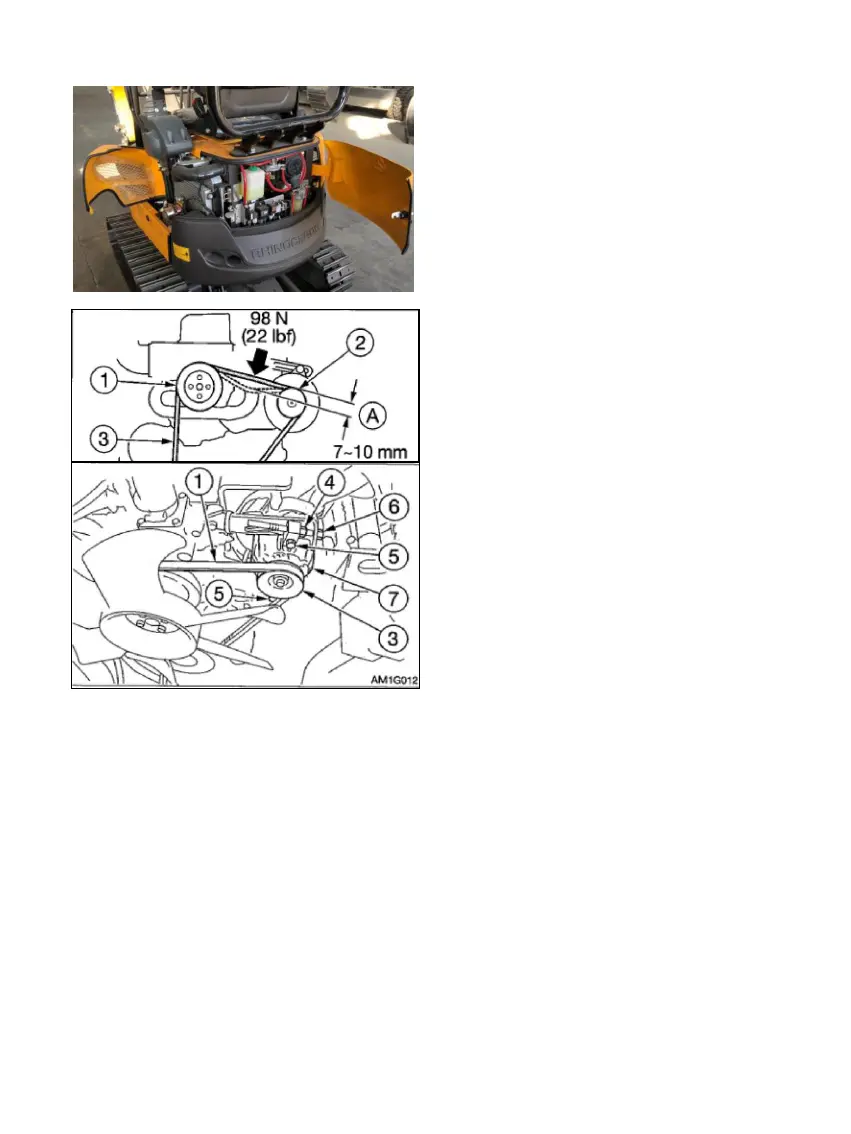

Check the tension (Approximately 98N) based

on the centers of fan pulley (1) and alternator

pulley (2).

Check the fan belt (3). Upon detection of any of

following conditions, replace.

Rupture or cracking.

The belt is worn to touch the bottom of pulley

V-grooves.

The belt is stretched loosely and is non-

adjustable.

Adjustment

Loosen bolt (5) and lock nut (4).

Rotate the adjustment bolt (6) to move the

alternator (7) and adjust the tension of fan

belt (1).

Increase tension: Clockwise Reduce tension:

Counter-clockwise

Tighten bolt (5) and lock nut (4).

Note: After the replacement with new belt,

run the engine at low idling speed for

approximately 3~5min to run in new belt and

then adjust the tension.

Replacement of hydraulic oil return filter

Slowly loosen the bleeding plug to relieve the pressure of oil tank.

While disassembling connector or plug or disconnecting hose, stand on one side, loosen slowly to

gradually relieve internal pressure, and then take out.

Warning

Please stop the engine and wait for the machine to cool down before maintenance.

The engine, hydraulic system, and many other parts are hot after operation. Touching such parts

can cause scalding. The hydraulic oil is also under high temperature and high pressure. Take caution

not to touch the hydraulic oil while loosening engine hood or connector. Operating the machine

under such condition can cause out-spray of hot oil which may result in scalding and injuries.

Loading...

Loading...