4.Installing Tx1500

1 Prepare the Turnstile assembly

th

tep:S

The floor where the turnstile will be fixed must meet the following specifications:

a. 1,6mm x l 1,4mm xDimensions: Direction of flow columns width concrete

height

10 cm;

b. ;Necessary height: 2. meters5

c. ;Level the floor for better product performance

d. ;Floor specification (FCK15 M.P.A. concrete or equivalent)

e. 1,6m

x 1,4m x 2,6m.Floor specification (FCK15 M.P.A. concrete or equivalent)

Power point input and network cable can be on the floor, preferably at point 3 or

overhead pipes.

Obs.:The dimensions of the concrete block and power inputs are only a suggestion.

The client can choose smaller bases (footing) at the fixing points (determined by

template).

List of tools for assembling the Turnstile:

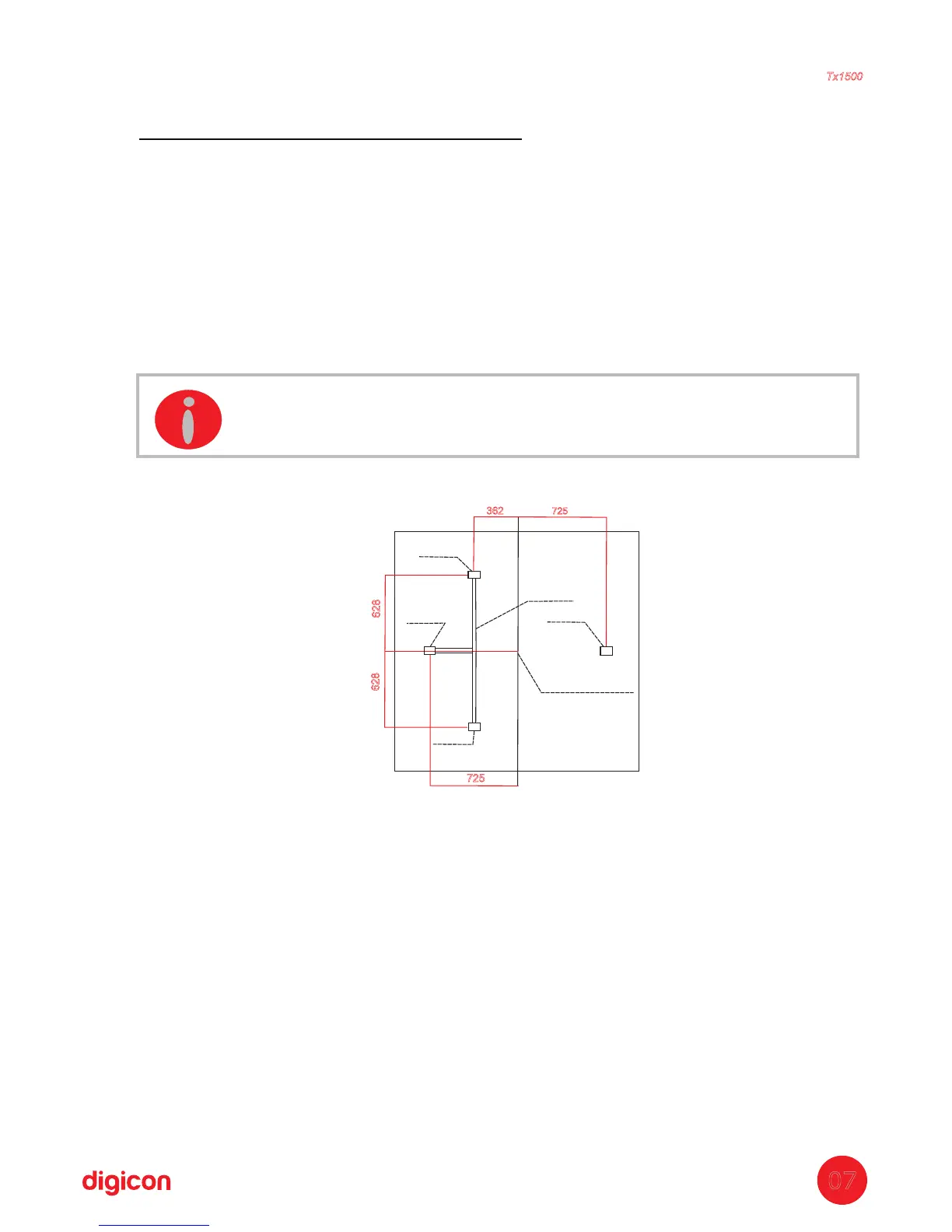

INFORMATION: Illustrative image (measures specified in “mm”).

Duct

Point 4

Reference point

Point 1

Point 3

Point 2

725

628

628

362

725

Torniquete

Tx1500

07

1 socket wrench with

socket of 14 and

17mm;

1 combination wrench

17;

1 socket wrench 10

with extension;

1 ;n.3 Allen wrench

1 n. 5 Allen wrench;

1

medium-sized

Philips screwdriver;

1 medium-sized

screwdriver;

1 hard plastic

hammer

1 plum-line or water

level;

1 silicone tube;

Molykote BR2 Plus

gr

aphite grease;

Step ladder with four

steps

;

Electric drill and drill

bits for concrete with

6 and 14 cm

;

Bolter – 10 parts for

every product.

Loading...

Loading...