E-8

English

7

Heat pump operation can be blocked as required if domestic hot

water is to be prepared using a second heat generator. This is

achieved by removing the factory-mounted copper bridge A2 (at

terminal strip X5, see Section 5.3) and integrating a floating con-

tact from the second heat generator regulation in the same posi-

tion. An external regulation must not lead to the maximum

switching frequency (12 operations/h) of the heat pump being ex-

ceeded. It may be necessary to take the local utility company

(EVU) specifications into consideration in this regard.

Relay for heat exchanger operation

Relay with a floating contact (hot-water heat pumps with internal

heat exchanger only) to control the ancillary devices (pump, so-

lenoid valve etc.) for operation with a second heat generator. The

relay contact is closed when the "Heat Exchanger" switch is acti-

vated and a hot water request from the hot-water heat pump tem-

perature controller is present.

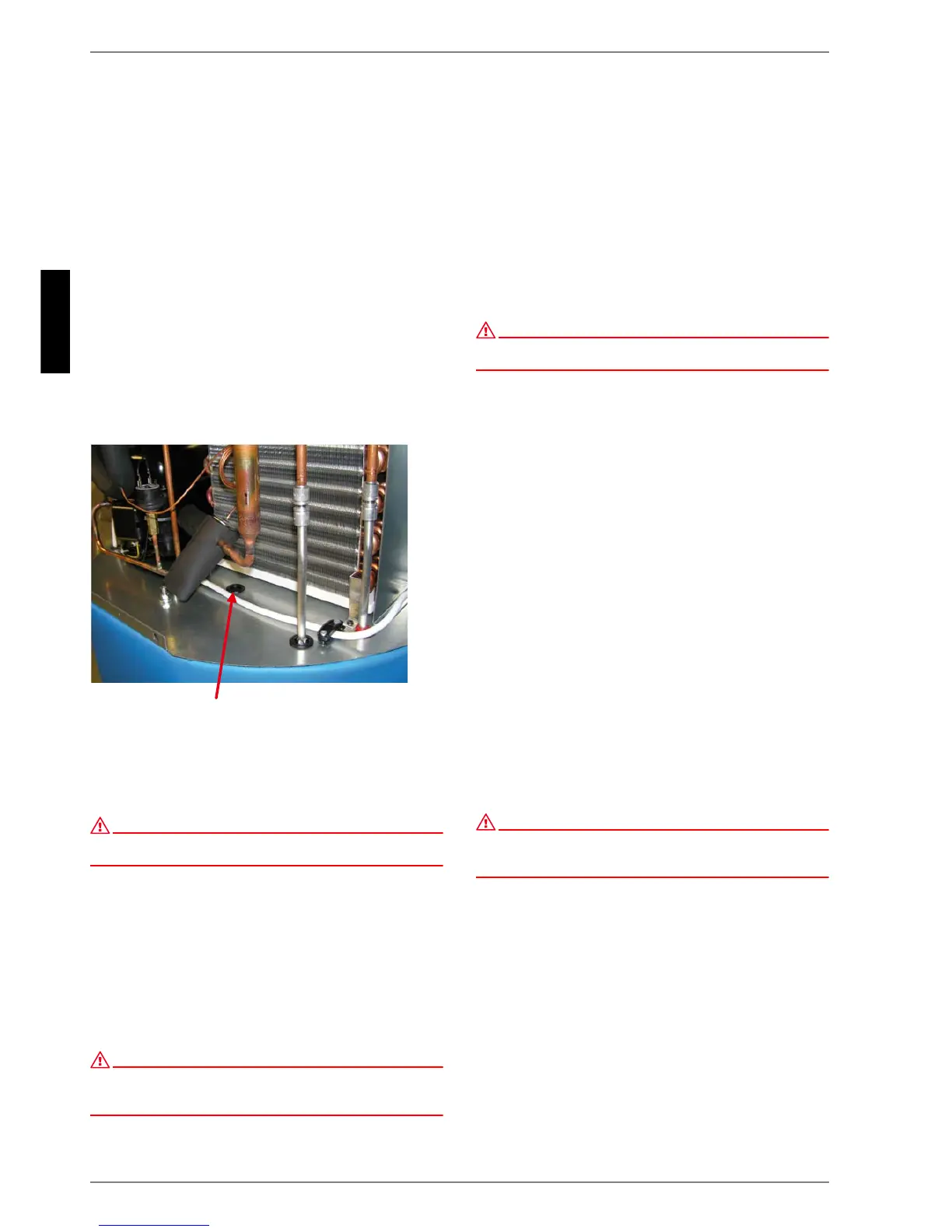

Sensor pipe for external temperature sensors

A vertical sensor pipe ∅

i

12mm (opening in the bottom plate

sealed with a leading-in tube) for an external heat sensor is fitted

in the rear of the hot-water heat pump and a cable feedthrough is

available in the rear panel.

External temperature sensor installation position

(device cover removed)

7 Maintenance

ATTENTION!

Disconnect the power supply before opening the hot-water heat pump;

observe possible coasting of ventilator.

General information

The hot water heat pump is virtually maintenance-free. A one-off

visual inspection for possible leakage in the water system or

stopping-up of the condensate outflow should take place a few

days after the maintenance work has been carried out.

Do not carry out any maintenance work on the refrigerating cir-

cuit of the heat pump.

Only use a damp cloth and soap solution for cleaning the hot-

water heat pump.

ATTENTION!

Ensure water does not come into contact with the operator controls.

Unplug mains plug/disconnect the power supply before beginning any

cleaning work.

7.1 Water Circuit / Condensate

Outflow

The water circuit check is limited to filters that may have been in-

stalled on-site, and possible leakage. Dirty water filters should be

cleaned and replaced if necessary. Occasionally check the seal

valve in the condensed water hose for contamination; replace if

necessary.

7.2 Air Circuit

Maintenance work is limited to cleaning the evaporator on a reg-

ular basis, and as needed.

ATTENTION!

Risk of injury caused by sharp-edged fins. Fins must not be deformed or

damaged!

If air filters are used, they should be regularly checked for con-

tamination and cleaned and replaced if necessary.

7.3 Corrosion Protection Anode

The corrosion protection anode installed in the hot water cylinder

should be electrically checked on a regular basis, at least every

two years after start-up, and be replaced if necessary. Electrical

checking is carried out by means of a suitable ammeter, without

draining the tank.

Procedure:

1) Unplug PE cable from protection anode tab.

2) Connect ammeter (0...50mA) between PE cable and tab.

3) Evaluation of protection anode wear:

Measured value > 1 mA ⇒ protection anode is in working

order.

Measured value < 1 mA ⇒ protection anode must be tested

or replaced.

If electrical testing does not provide any clear results, a visual in-

spection of the protection anode by a technician is recom-

mended.

Should replacement of the protection anode [by a technician] be

necessary, the tank must be drained via the valve provided (fitted

during installation - see Appendix).

ATTENTION!

Malfunctioning protection anodes reduce the operating life of the device!

(Reactive anode: electrically insulated magnesium anode with selenium

according to DIN 4753 Part 6)

Loading...

Loading...