An inverter compressor starts gently ramping up to its

maximum speed over a couple of minutes meaning the

current increase is very gradual. The fixed speed

compressor has a larger starting current because it

doesn‟t turn on gradually. The starting current is smoothed

by an inbuilt soft-starter to keep it within acceptable limits.

The starting current does not cause any problems

because an in-built randomised time delay that ensures

multiple heat pumps to not turn on at the same time.

An inverter heat pump is able to modulate down its output

as the external temperature increases. A fixed speed heat

pump will run at a constant speed meaning that its output

increases with rising temperature. This means that an

inverter compressor could achieve slightly higher cylinder

temperatures for the same size coil although in practice

both types of compressor can achieve suitable cylinder

temperatures.

Advantages of fixed speed compressors

A fixed speed compressor is designed to work at the

optimum performance level all of the time. An inverter

compressor does not always work in the optimum zone

because it modulates its output to match the heat demand.

The „over-driving‟ of an inverter compressor causes it

efficiency to drop.

Since the output of both the fixed and inverter

compressors drop with decreasing temperature, there

becomes a point when a secondary heat source is

required to match the properties heat demand, known as

the Bivalent point. At lower temperatures an inverter

compressor and a fixed speed compressor are equally as

efficient despite the inverter needing more immersion

support.

Heat pump labelling

The product code for the inverter range of heat pumps

continues the same convention as the rest of Dimplex‟s

heat pump range.

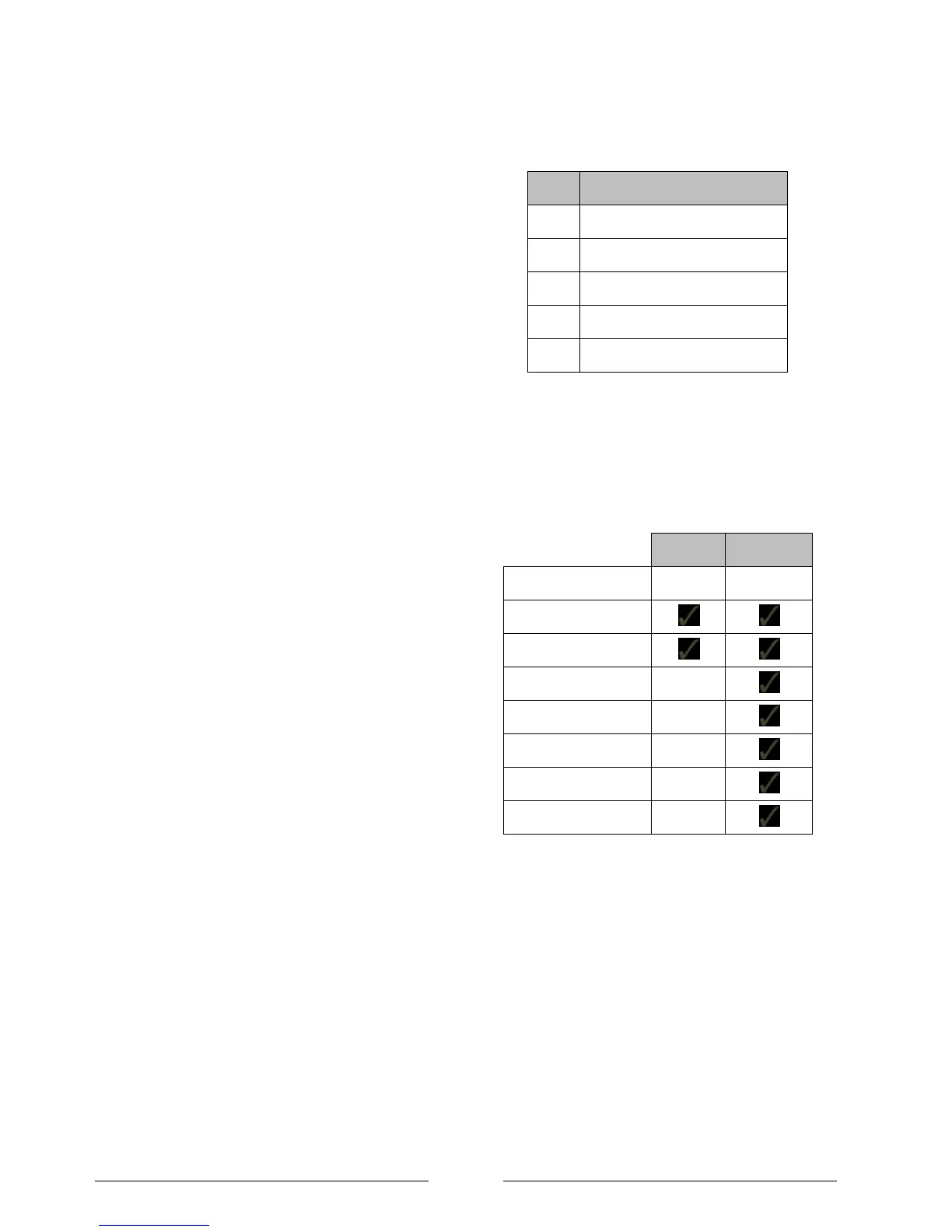

Table 1: Product coding convention

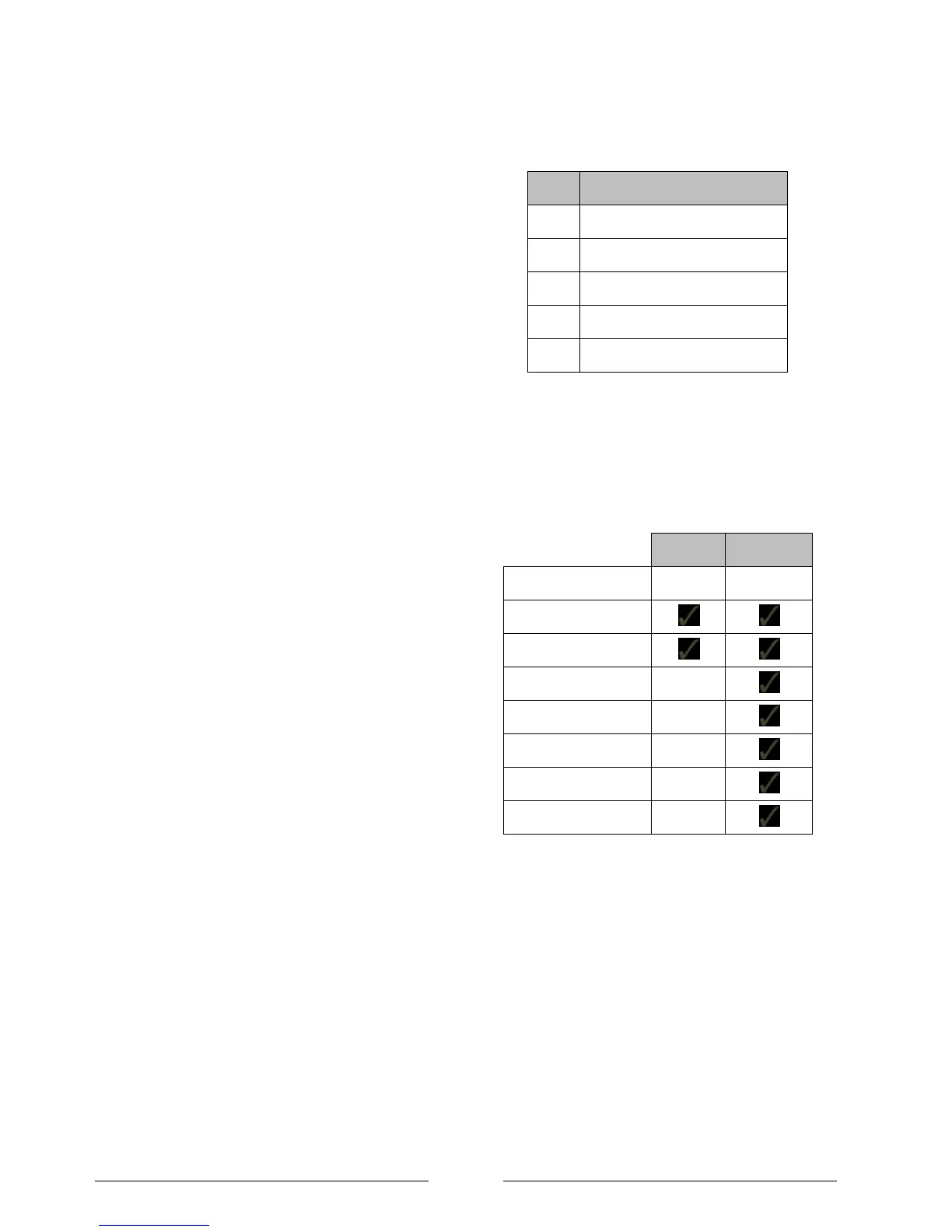

Comparison of the LA MS and LA MI ranges

The LA MI and LA MS range of heat pumps are ideal for

providing DHW and space heating. In addition, the MS

range of heat pumps also has a sophisticated controller

capable of controlling more complicated systems.

Loading...

Loading...