Convection Heated Plate and Base Dispenser | 3

6. To set the proper spring tension and dispensing level,

place ten wax bases in the self-leveling dispenser on right

side of unit (Figure 1). Add or remove springs by hooking or

unhooking the bottom of the spring from the moving carriage

as necessary, until the top wax base is positioned at the

top of the dispenser unit (Figure 2).

!

NOTE: Steps 6 -8 are for Combination Plate/Base Heaters but may

be followed accordingly for plate or base only dispensers. Spring

adjustment not covered under warranty.

7. Repeat step 6 with plates for the other self-leveling

dispenser unit. In general, fewer springs will be needed to

maintain proper level for plates than for bases.

8. Remove all bases and plates from the self-leveling

dispensers, and carefully lower the self-leveling

dispensers back into the cabinet, taking care to place

base and plate dispensers in the appropriate side.

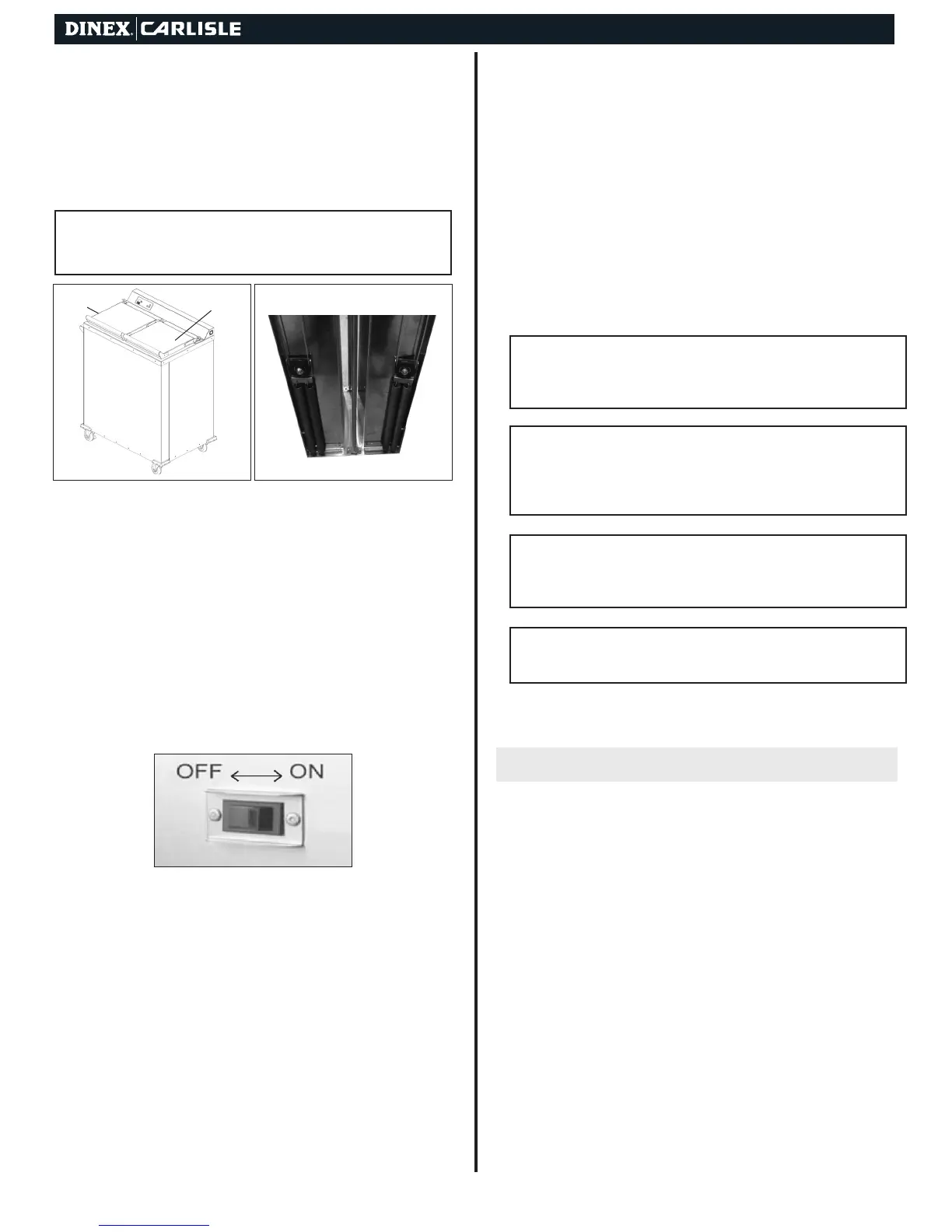

9. Be sure the power switches are in the OFF position before

plugging the power cord into the electrical outlet (Figure 3).

10. Select a location within reach of a 208, 220, 240 VAC,

60 Hz grounded NEMA No. 6-20R (2 Silo) or NEMA

No. 6-50R (3 silo) electrical outlet.

11. Place the unit near enough to the electrical outlet so

that the power cord is not stretched or strained when

plugged in.

12. When unit is properly located, engage the two caster

brakes by pushing down on the wheel brake lever.

13. See ELECTRICAL and START-UP sections before

plugging unit into power supply.

START-UP

Overview

These units are designed to heat stainless steel bases and

china plates. The fan motor, heating element, and power indi-

cator light will come on once the unit is turned on.

The fan motor will begin to circulate the heated air in

and around the plates/bases in a convection process that

promotes a quick and even heat absorption by the

plates/bases.

Once the air inside the cabinet has reached the desired and

preset temperature, the thermostats will continue to maintain

this temperature by regulating the power to the heating

element. The fan motor will run as long as each compartment

is energized.

ELECTRICAL

Refer to the General Information Section on page 2, your

local code or the National Electrical Code to be sure the unit is

connected to the proper power source. A protected circuit of

the correct voltage and amperage must be available for

connection of the line cord. Place the unit near enough to the

electrical outlet so the power cord is not stretched or strained.

Once the unit is properly located, push down on the two caster

brakes to lock them into place. All base/plate heaters are

provided with a NEMA plug type 6-20P (2 Silo) or 6-50P

(3 Silo).

!

WARNING: Every base/plate heater is fitted with a grounded power

cord and must be connected to a properly grounded receptacle.

Each receptacle must be wired to a dedicated circuit breaker rated

at not more than 20 amps (2 Silo) or 50 amps (3 Silo).

!

WARNING: To prevent electrical shock hazard, the main power

switch must be turned to “off” position and the heater disconnected

from the power source whenever performing service or

maintenance.

!

WARNING: Hazardous voltage inside back of cabinet. Only

qualied personnel familiar with electrical circuits, service manual,

and service procedures should open or work inside unit.

!

WARNING: Unit must not be run continually and must be turned off

after final meal service. Warranty may be voided if used improperly.

Figure 3

Figure 2

Figure 1

OPERATION INSTRUCTIONS

Plate Cavity

Pellet/Wax

Base

Loading...

Loading...