DK-1100A Ink Roll Coder Operation Manual

3.2 Relocation

3.2.1 Check the Home Position of Type Holder

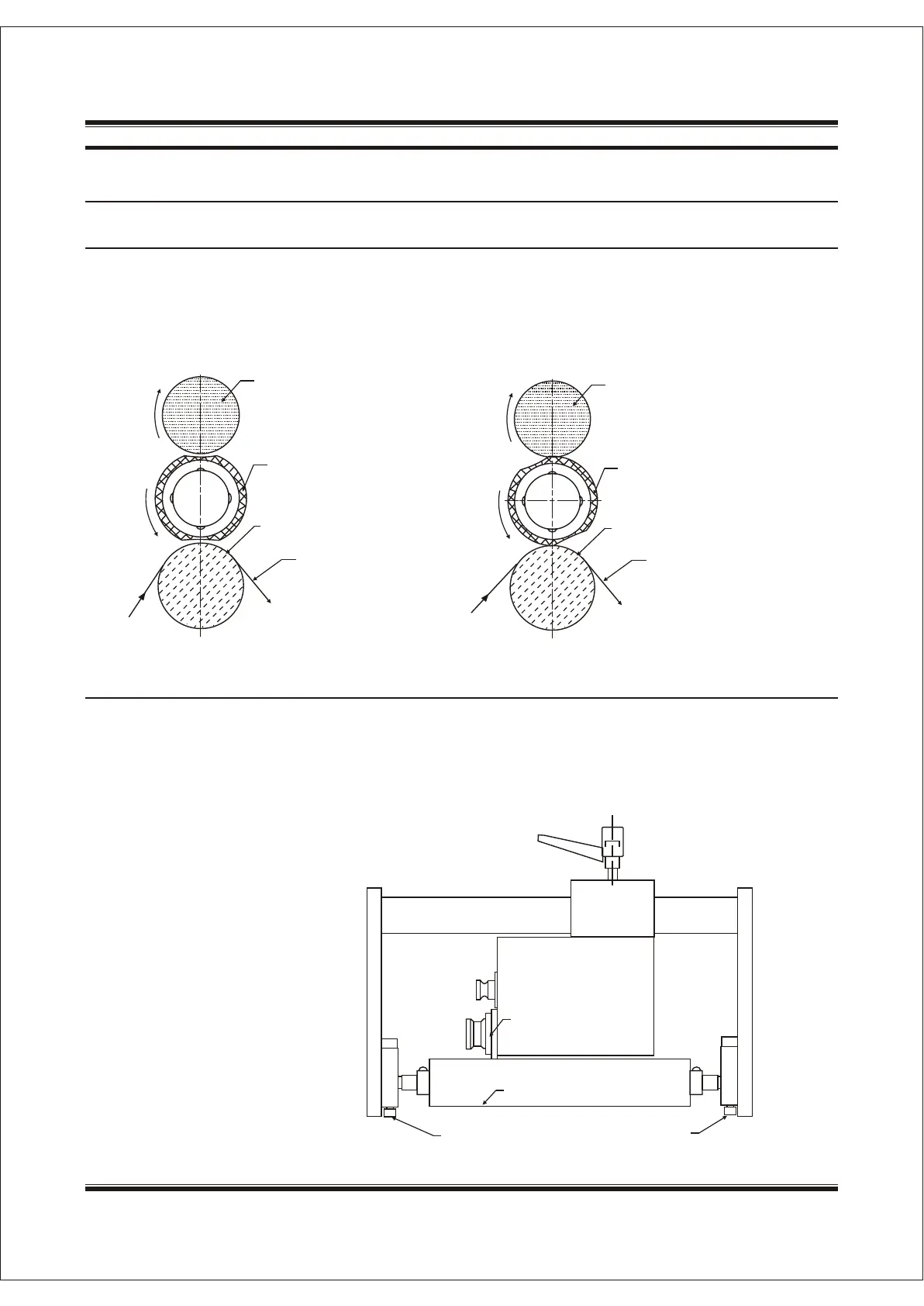

In the initiate position, any one of grooves around the type holder is faced to the pressure roller, no

contact (as diagram 10). After getting the print signal, the type holder contacts pressure roller reliably (as

diagram 11), to complete one print. Failure to do so can result in the failed or missed prints (it can

relocate the pressure between rubber wheel and pressure roller to get the clear prints, refer to 3.2.2).

3.2.2 Relocating the Pressure between Pressure Roller and Rubber Wheel

Ink RollInk Roll

Typr RubberTypr Rubber

Rubber RollerRubber Roller

FilmFilm

Diagram 10 Diagram 11

Ink RollInk Roll

Typr RubberTypr Rubber

Rubber RollerRubber Roller

FilmFilm

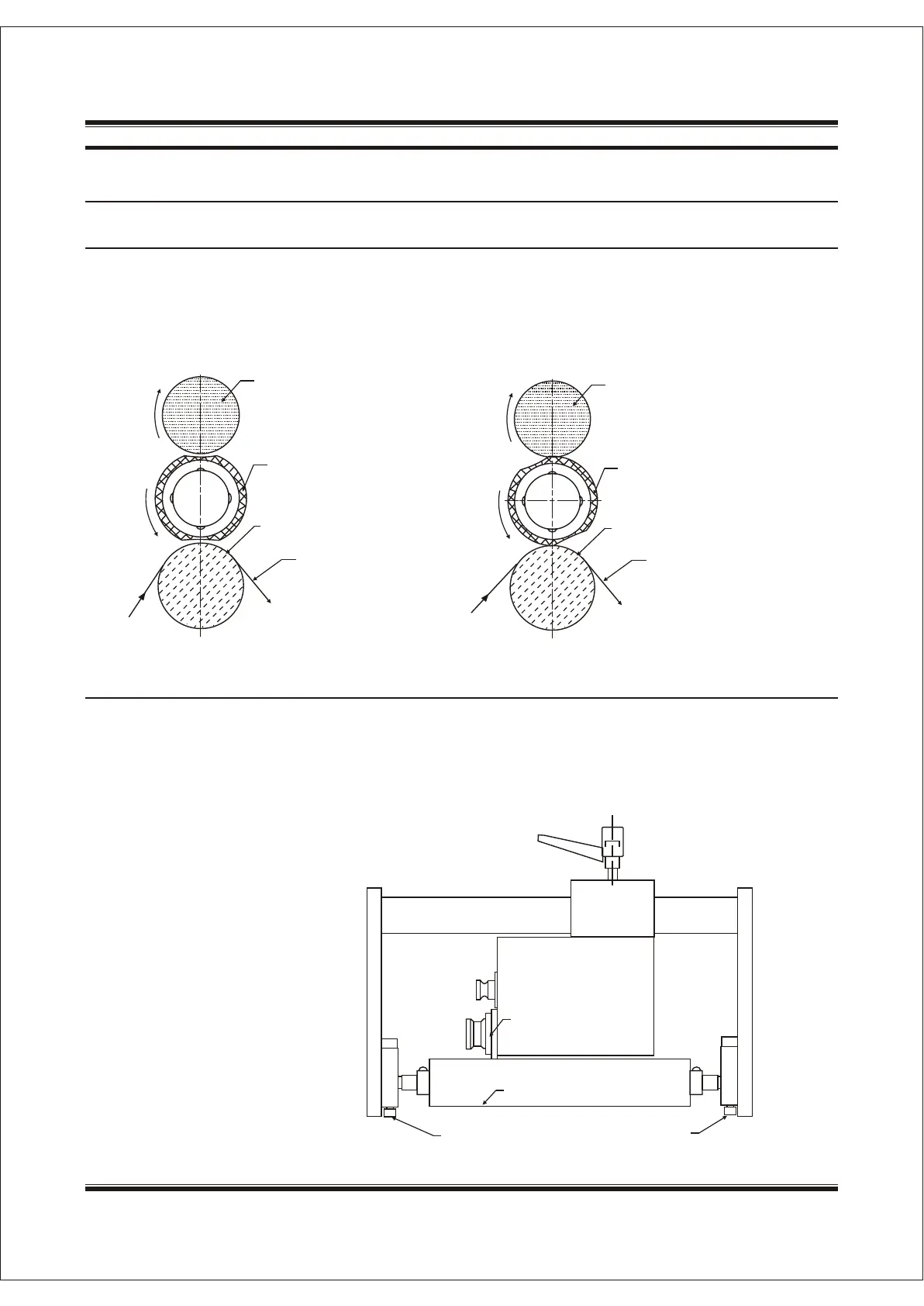

As diagram 12, the pressure and parallelism between pressure roller and rubber wheel can be

relocated by adjusting the screws and the horizontal position of adjusting wedges. This relocation makes

the correct position between pressure roller and rubber wheel, to get legible prints. When relocating, the

operator can press the test button in the control box to make type holder rotate and check whether the

pressure and position is correct.

Diagram 12

Adjusting wedge

Type HolderType Holder

Rubber RollerRubber Roller

Adjust screwAdjust screw

Adjust screwAdjust screw

SHANGHAI DIKAI SEPARATE MACHINERY CO., LTD.SHANGHAI DIKAI SEPARATE MACHINERY CO., LTD.3-173-17

Loading...

Loading...