1-14 (No.HD003<Rev.004>)

2.6 Check details after mounting separately sold parts

Item Check details Required tools

1 Reform H unit The warpage of the printed card should be within the specs (1.5

mm).

Blank card

2 IC Contact unit Check the IC contact position mark using a blank card and a

contact label.

• Service mode > Offline Test > Test the IC (Contact).

• If the position is out of specs, Maintenance > OffsetContact to

adjust the position. (See 2.3.1 IC contact position adjustment)

Blank card, Contact label

The card written with an application should be read by the read-

er.

(Check in the USB and Ethernet connections)

Contact IC card

Contact IC reader

3 MG Unit Service mode > Offline Test > test the MG.

• The test should be finished normally.

MG card

The card written with an application should be read by the read-

er.

• There is no adjustment for an MG unit after mounting because

MG units are shipped after being position adjusted. Check for

normal operation only.

MG reader

4 Running after mounting the

separately sold parts

(For all separately sold parts)

Test for normal printing on about 10 cards

• Service mode > Offline Test > print

Evaluation card

Item Item Conditions & specs Test point

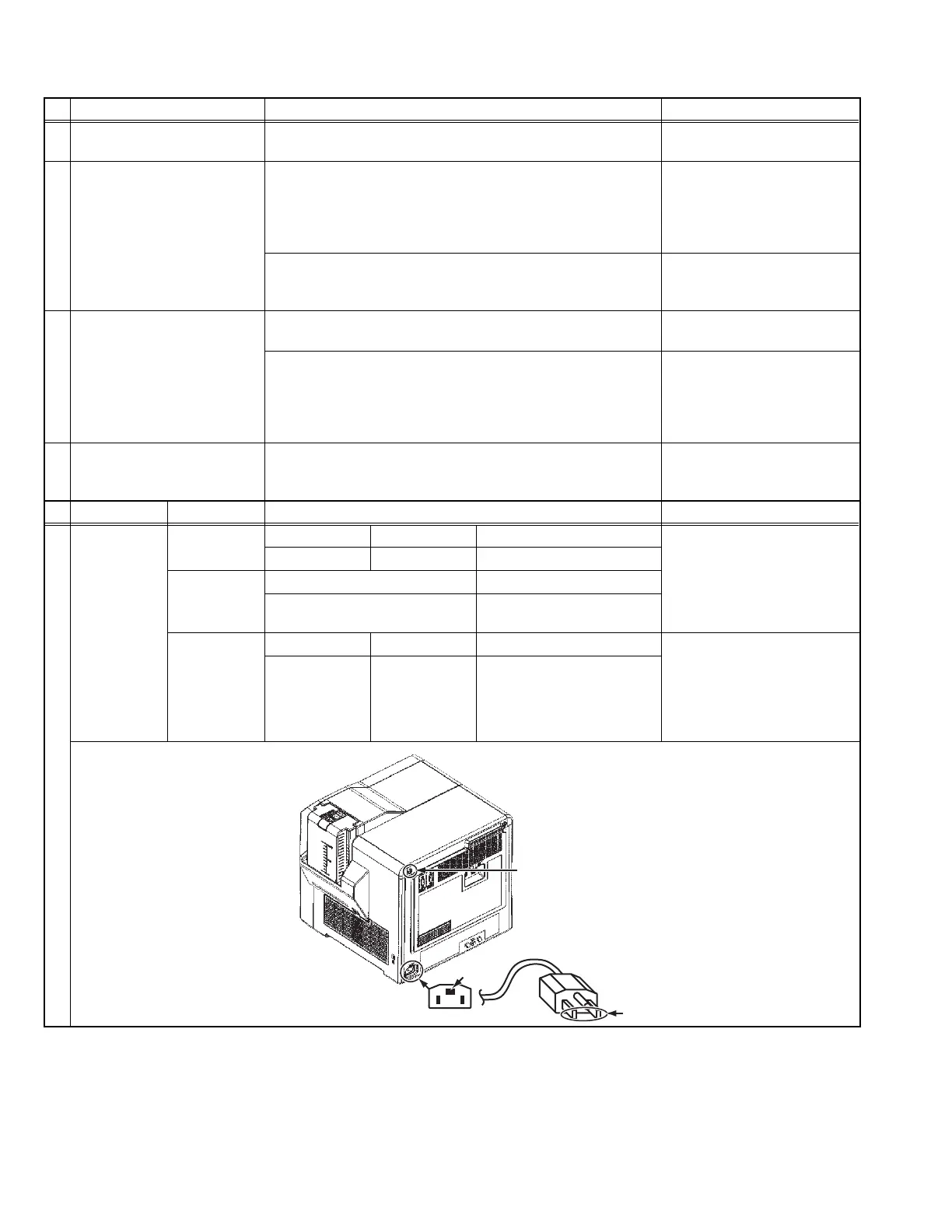

5 Safety test (for

all separately

sold parts)

Withstand

voltage test

Timer Leak current Test voltage (With the POWER SW: ON)

GND C on the AC inlet in the

drawing below

|

Bipolar B on the power cord in

the drawing below

2 to 3 sec. 30mA AC1600±50V

Insulation re-

sistance test

Test voltage Insulation resistance value

DC 500V 100M and over

Grounding

continuity test

Timer Test current Spec value (With the POWER SW: ON)

Screw A on the top left of the

rear panel in the drawing below

|

GND C on the AC inlet in the

drawing below

3 to 4 sec. AC25A 0.1 or under

(Without power cord)

A

B

C

Loading...

Loading...