6950 51st Street Kenosha WI 53144|Orders and Customer Care: 1-800-574-7665|Fax: 1-800-323-5932|Doheny.com

C. Motor Hums, But Does NOT Start – Check For:

1. Impeller jammed with debris.

Solution:Haveaqualiedrepairprofessionalopen

the pump and remove the debris.

D. Pump Won’t Prime, Check For:

1.

Empty pump/strainer housing.

Solution:Makesurepump/strainerhousingislled

with water and cover O-Ring is clean. Ensure O-Ring

is properly seated in the cover O-Ring groove.

Ensure O-ring is lubricated and that strainer cover

is locked rmly in position. Lubricant will help to

create a tighter seal.

2. Loose connections on suction side.

Solution: Tighten pipe/union connections. NOTE:

Any self-priming pump will not prime if there are

suction air leaks. Leaks will result in bubbles

emanatingfromreturnttingsonpoolwall.

3. Leaking O-ring or packing glands on valves.

Solution: Tighten, repair, or replace valves.

4. Strainer basket or skimmer basket loaded with

debris.

Solution: Remove strainer housing cover or

skimmer cover, clean basket, and rell strainer

housing with water. Tighten cover.

5. Suction side clogged.

Solution: Contact a qualied repair professional.

Block off to determine if pump will develop a

vacuum. You should have 5 in. to 6 in. of vacuum

at the strainer cover (Only your pool dealer can

conrm this with a vacuum gauge). You may be

able to check by removing the skimmer basket and

holding your hand over the bottom port with

skimmer full and pump running. If no suction is felt,

check for line blockage.

a. If pump develops a vacuum, check for blocked

suction line or dirty strainer basket. An air leak

in the suction piping may be the cause.

b. If pump does not develop a vacuum and pump

hassufcient“primingwater”:

i. Re-check strainer housing cover and all

threaded connections for suction leaks.

Check if all system hose clamps are tight.

ii. Check voltage to ensure that the motor is

rotating at full RPM’s.

iii. Open housing cover and check for clogging

or obstruction in suction. Check impeller for

debris.

iv. Remove and replace shaft seal only if it is

leaking.

E. Low Flow – Generally, Check For:

1. Clogged or restricted strainer or suction line.

Solution:Contactaqualiedrepairprofessional.

2. Undersized pool piping.

Solution: Correct piping size.

3. Pluggedorrestricteddischargelineoflter,valve

partially closed (high gauge reading).

Solution: Sand Filters: backwash as per

manufacturer’s instructions; D.E. Filters: backwash

as per manufacturer’s instructions; Cartridge Flters:

clean or replace cartridge.

4. Air leak in suction (bubbles issuing from return

ttings).

Solution: Re-tighten suction and discharge

connections using Teon tape. Inspect other

plumbingconnectionsandtightenasrequired.

5. Plugged, restricted, or damaged impeller.

Solution: Replace including new seal assembly.

F. Noisy Pump – Check For:

1. Air leak in suction piping, cavitations caused by

restricted or undersized suction line or leak at any

joint, low water level in pool, and unrestricted

discharge return lines.

Solution: Correct suction condition or throttle

return lines, if practical. Holding hand over return

ttingwillsometimesprovethispointorputtingina

smallereyeballtting.

2. Vibration due to improper mounting.

Solution: Mount the pump on a level surface and

securethepumptotheequipmentpad.

3. Foreign matter in pump housing. Loose stones/

debris hitting impeller could be cause.

Solution: Clean the pump housing.

4. Motor bearings noisy from normal wear, rust,

overheating, or concentration of chemicals causing

seal damage which will allow chlorinated water

to seep into bearings, wiping out the grease and

causing bearing to whine.

Solution: All seal leaks should be replaced at once.

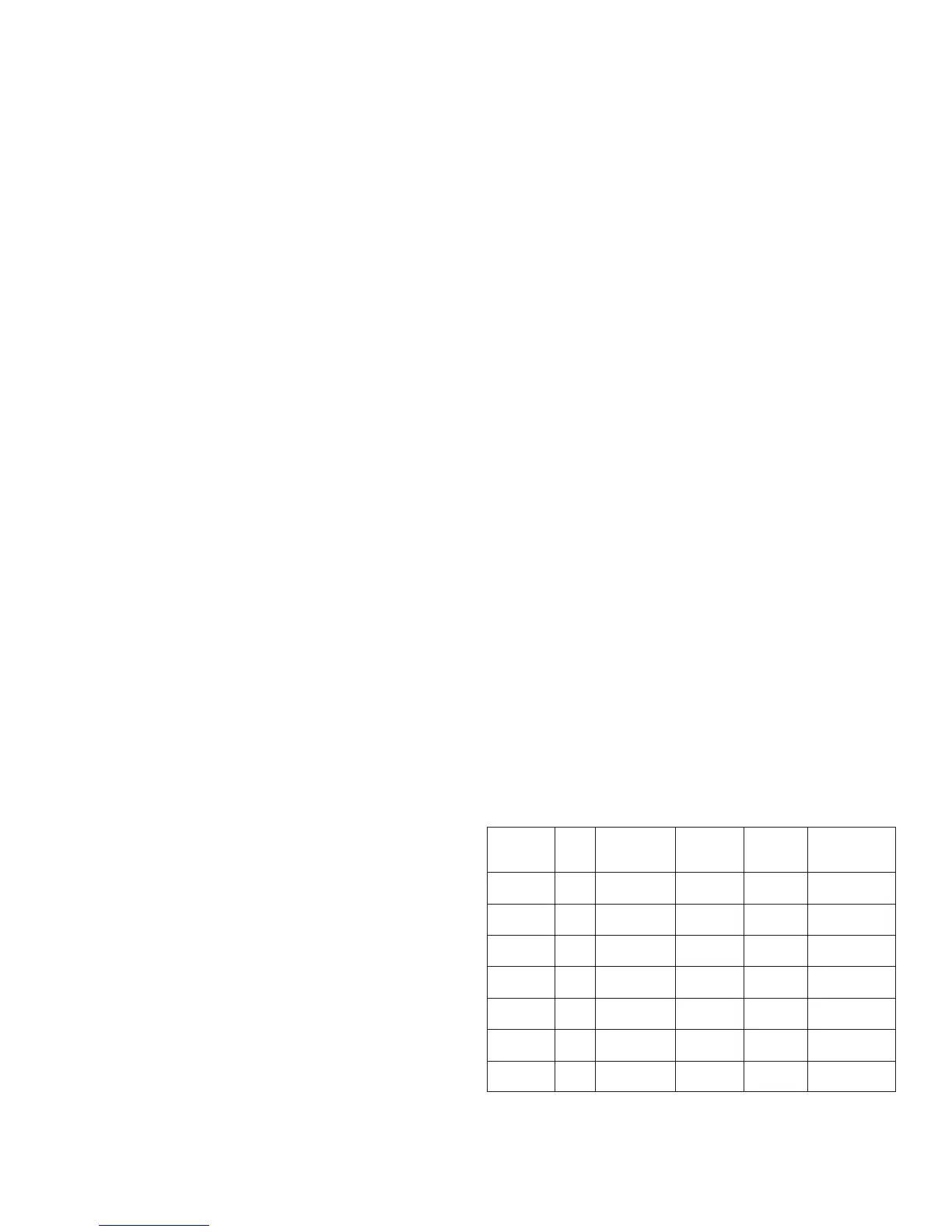

CHAPTER 8: TECHNICAL DATA

Pump performance table

ITEM# HP VOLT AMPS MAX MAX

(GPM) HEAD (ft)

2601 3/4 115 7.3 62 30

6578 1 115 9 75 38

6579 1.5 115 12 83 40

2716 1 115/230 11.5/5.7 83 15

6589 1.5 115/230 14.2/7.1 97 20

4657 1 115 11.5 82 50

5014 1.5 115 15 95 68

Loading...

Loading...